Examples of the application and benefits of Artificial Intelligence (AI) in industrial automation in manufacturing are numerous, including:

- Anomaly Detection and Production Optimization

- Predictive Maintenance

- Improved Product Quality and Consistency

- Energy Efficiency and Waste Reduction

- Data-driven Decision Making

In this best opportunity, the Bawalaksana.id team would like to discuss an interesting topic that is currently popular in the Digital Factory era, namely the benefits of Artificial Intelligence (AI) in industrial automation in manufacturing, examples of its application and how to implement it.

When did AI start being discussed in the industry?

The integration of artificial intelligence (AI) in industrial automation in manufacturing has been a much-discussed idea since the 1960s. These were the early years of the development of Artificial Intelligence (AI) and Neural Networks.

However, the idea was too advanced for its time, so plans to involve AI in the industrial sector tended to be ignored.

Initially, engineers had a vision that AI would be the key to improving production efficiency and scale, without having to rely on human labor. However, due to technological limitations at that time, the grand vision of integrating AI with industrial automation could not be realized properly.

The Turning Point of AI Utilization in Industrial Automation and Manufacturing

In the early days of AI and neural networks, AI systems required enormous computing power.

This technology requires large computing machines that can generate heat and high energy consumption. With reasons related to energy efficiency, the application of AI technology for industry is still considered far from feasible.

Then in the 2010s, AI came back into the spotlight with the rapid advancements in hardware, the emergence of the Internet of Things (IoT), and the widespread implementation of cloud computing and edge computing.

Technological advancements in recent years have paved the way for large-scale collection and processing of industrial data.

This convergence of technologies has finally brought back the spirit of realizing the original vision that was buried decades ago. That is applying artificial intelligence (AI) in industrial automation and manufacturing.

AI Integration in Industrial Automation in Manufacturing Using PLCnext Technology

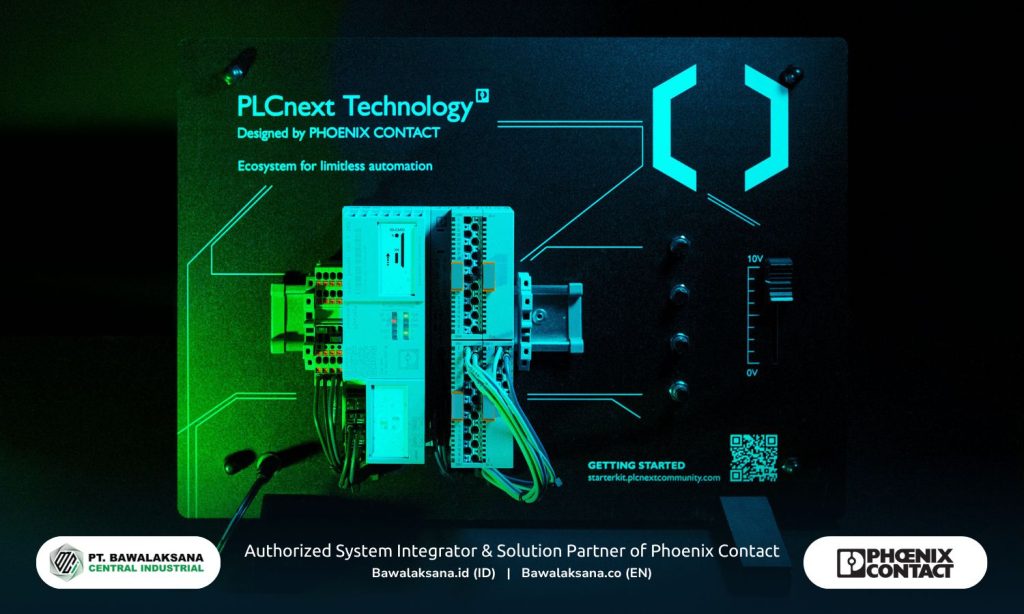

One of the major breakthroughs in modern industrial automation is the arrival of PLCnext Technology. This advanced platform developed by one of Europe’s leading OEMs, Phoenix Contact, offers the capability to run AI either through the edge or the cloud.

PLCnext Technology is different from conventional PLCs in general, because it has a flexible programming ecosystem.

Users can develop applications in various languages, such as C, C++, Python, Ladder Logic, Function Block, Matlab or Structured Text, then integrate them seamlessly through the Global Data Space (GDS).

GDS serves as a unified variable layer that enables real-time data exchange between programming languages without compatibility issues.

In addition, the Execution and Synchronization Manager (ESM) feature enables flexible task scheduling along with high-performance deterministic multitasking. With these various advantages, PLCnext is far superior compared to conventional PLCs in general.

PLCnext Technology as an Ecosystem for the Digital Factory

PLCnext Technology is an ecosystem for industrial automation in the manufacturing sector that can bridge between Operational Technology (OT) and Informational Technology (IT) seamlessly and practically. The PLCnext Technology ecosystem offers an open control platform, modular engineering software and a digital store marketplace to facilitate the gradual digital transformation for a successful and sustainable Digital Factory.

With simple cloud integration, the option to use open source software and a solid and growing community, brings PLCnext Technology as the best means to face all the challenges of the Industrial Internet of Things (IIoT) world.

Meanwhile, data is a vital part of the Digital Factory concept, as well as a key asset for creating quality processes, improving productivity, efficiency, safety and sustainability in manufacturing environments and the world at large.

Historically, the integration of OT and IT has been difficult because they use different communication protocols and technologies. As such, data exchange between them is very limited, difficult, time-consuming and expensive. This results in fragmented data in “data silos” (data isolated in one system only), making the discourse to achieve manufacturing digitization difficult to implement.

Therefore, PLCnext Technology is here to answer this problem with extensive and easy integration without the need for complex programming skills, namely by using the “IIoT Framework”.

It is important to note that the Digital Factory initiative comes from a far-sighted vision and constructive awareness to build an industry that supports climate and environmental sustainability, in an effort to achieve the 1.5°C target and net zero factory by 2050.

Data is the most important asset of your business in creating a carbon-neutral industry, through digitized and data-driven operations.

However, it needs to be recognized that building an advanced Digital Factory requires smart solutions to increase productivity, improve availability and generate new business models. Through the PLCnext Technology ecosystem and Phoenix Contact’s extensive portfolio, you can achieve extensive scalability and flexibility in your journey towards a true Digital Factory.

For complete information on what is Digital Factory, the technology needed, case studies and the stages of implementation, please go to our article What is a Digital Factory? The Future of Industrial Automation and Green Manufacturing.

Benefits of AI in Industrial Automation and Manufacturing

As we mentioned above, PLCnext technology offers extensive flexibility and capability to run AI and integrate it in industrial automation.

At the same time, PLCnext Technology has opened up a new, powerful architecture to increase industrial productivity.

For example, one task may retrieve data from sensors in parallel, while another task simultaneously runs AI inference using that data directly at the edge.

Alternatively, data can be sent to the cloud via protocols such as MQTT and complex AI models run remotely, and the results accessed back by the PLC. This progress opens up great opportunities for the application of AI in various advanced industrial cases, such as Machine Learning (ML)-based anomaly detection.

The following are some examples of the application of artificial intelligence (AI) in industrial automation and its benefits:

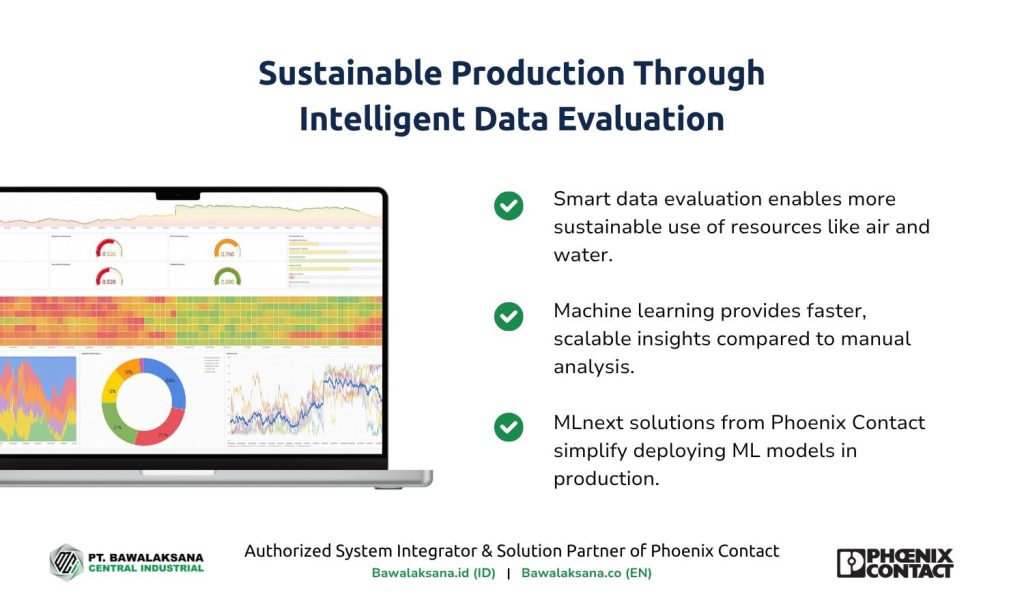

Anomaly Detection and Production Optimization Using AI

Artificial intelligence (AI) enables early detection of anomalies or deviations in the production process automatically and in real time. This capability can help the engineering team to identify potential problems before they cause damage or degradation of product quality.

One important technology for performing tasks like this is Phoenix Contact’s MLnext which can be used to create Machine Learning (ML) algorithms to recognize unusual patterns in production data. This method can help engineers to take corrective actions more quickly and efficiently.

Thus, continuous optimization of the production process can be carried out with evaluation data from AI, thereby increasing efficiency and lowering operational costs.

Predictive Maintenance

Artificial Intelligence (AI) is capable of analyzing sensor data and machine history to predict when equipment will fail. This capability can help engineers to know when maintenance can be scheduled before a breakdown occurs.

It is known that Predictive Maintenance requires proper planning, so that downtime can be minimized and proper maintenance helps in extending the life of industrial devices.

By utilizing AI in manufacturing, the engineering team can plan appropriate and effective Predictive Maintenance, so that sudden repair costs and lost production time can be significantly reduced.

Improved Product Quality and Consistency

Performing visual inspections automatically and quickly can also be done by AI, using special cameras and lenses (computer vision) to detect manufacturing defects based on color spectrum analysis.

Vision-based inspection systems equipped with high-resolution cameras and deep learning algorithms are capable of detecting even the slightest product defect in a matter of milliseconds.

Meanwhile, in electronics manufacturing, AI is used to detect micro-defects on circuit boards with almost 99% accuracy.

This is among the important benefits of AI in performing quality inspections automatically and consistently on every product, not just sampling. This increases the accuracy of defect detection and reduces failed products reaching customers. .

When customers are satisfied with the quality and quality of your company’s products, it will increase competitiveness and generate powerful positive reviews.

It is also worth noting that artificial intelligence (AI)-based inspection systems can improve in quality over time by learning from previously recorded defect data. That way, the ability to detect failed products will be more accurate and effective.

Energy Efficiency and Waste Reduction

When potential production problems can be prevented, predictive maintenance can be scheduled properly and production defects can be detected properly, the output will be energy efficiency and waste reduction.

Even with the help of AI, your company can improve product quality and consistency which contributes to customer satisfaction.

This condition is the expected sweet fruit of the Digital Factory implementation. That is, when the production process can be more efficient and waste can be significantly reduced, the emission of carbon substances can also be minimized. At the same time, the competitiveness and resilience of the business can be sustainably improved…

In short, artificial intelligence (AI) helps you to optimize the use of energy and raw materials by automatically adjusting production parameters based on realtime data. As a result, maximum efficiency is easily achieved and production waste is minimized. .

Data-driven Decision Making

Data driven decision making is vital for sustainable business. The question is, how can you achieve this if the data acquisition process on the factory floor is not optimized?

Therefore, implementing the right technology and software in your manufacturing is an important investment for business sustainability.

AI integration in industrial automation makes it easier for you to make data-driven decisions. In fact, AI can also process production data thoroughly and provide recommendations or make decisions automatically for process adjustments.

This advantage can provide good agility to your automation system to be able to respond to any changes in conditions more quickly and precisely.

In conclusion, PLCnext Technology with its open and scalable ecosystem, makes it easy to integrate AI in industrial automation. This is no longer just theoretical, but a practical step towards a sustainable and scalable Digital Factory era.

Some of the benefits of AI that we have mentioned above are the main foundation in the implementation of Digital Factory, which is now the main focus of industrial transformation to achieve higher efficiency, flexibility, and competitiveness in the industrial era 4.0.

Start Implementing AI in Industrial and Manufacturing Automation with PLCnext Technology

Technological advances in computing and hardware have become a bridge to realize the integration of AI into industrial automation systems. Although this idea was considered too advanced in its early days, we are now witnessing that the integration of AI into industry is already in great demand.

Thanks to Phoenix Contact’s innovative PLCnext Technology and its flexible programming ecosystem, the implementation of Artificial Intelligence (AI) in industrial automation is seamless, easy and smooth.

PT. Bawalaksana Central Industrial as Authorized System Integrator and Solution Partner for Phoenix Contact can be your partner to realize this big goal.

With over a decade of experience in the pneumatic industry and industrial automation systems, we have the professional experience and capability to implement AI technology in your industry.

We can help you with smart data acquisition, AI-based auditing, and predictive and preventive maintenance. We are your best partner to step into Industry 4.0 with confidence.

If you are interested in implementing artificial intelligence (AI) in your industry or would like to know more about Phoenix Contact’s PLCnext Technology, please connect with our professional team.

Click the consultation button below to start talking to our team of Application Engineers today.

Piko Prasetyo

Application Engineer

This article was written in collaboration with Piko Prasetyo, an expert in Automation, Embedded Systems and Artificial Intelligence, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)