Pneumatic Gripper is a mechanical device for material handling in industrial applications. Its function is to lift, pick, assemble, test and various other jobs on the production line.

Explore the cutting-edge world of industrial automation with our blog, offering the latest insights and practical tips to enhance your company’s productivity.

Pneumatic Gripper is a mechanical device for material handling in industrial applications. Its function is to lift, pick, assemble, test and various other jobs on the production line.

The Air Service Unit has three main functions: filter (F), regulator (R) and lubricator (L), hence the name FRL Unit. All three functions are accommodated by three separate and modular components.

Clean air is beneficial for maintaining the durability of the components and productivity of the pneumatic system. Meanwhile, controlled air contributes to improving safety and security aspects.

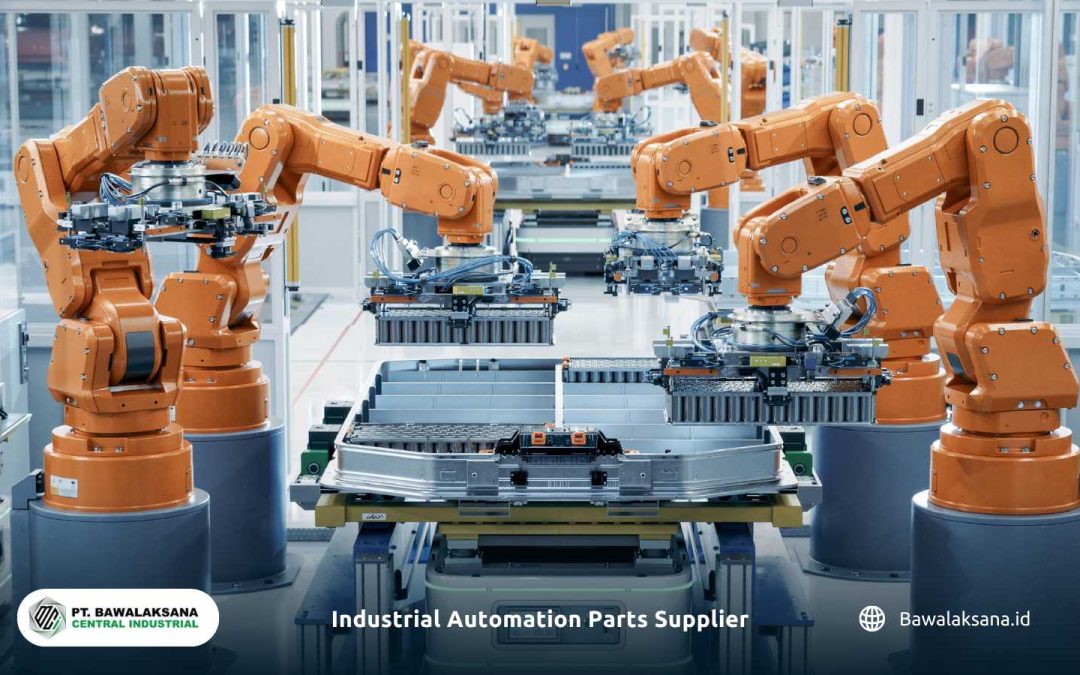

Bawalaksana.id provides various technologies and hardware for production system automation as well as the main foundation in building smart manufacturing (future-ready operation).

In the food and beverage (F&B) industry, the use of Nitrogen gas is common, especially in the packaging process.

Industrial power supplies are important components that contribute to providing a stable supply of voltage and current to various equipment, machines and control systems in manufacturing.

Clean air is beneficial for maintaining the durability of the components and productivity of the pneumatic system. Meanwhile, controlled air contributes to improving safety and security aspects.

Bawalaksana.id provides various technologies and hardware for production system automation as well as the main foundation in building smart manufacturing (future-ready operation).

In the food and beverage (F&B) industry, the use of Nitrogen gas is common, especially in the packaging process.

Pneumatic Gripper is a mechanical device for material handling in industrial applications. Its function is to lift, pick, assemble, test and various other jobs on the production line.

The Air Service Unit has three main functions: filter (F), regulator (R) and lubricator (L), hence the name FRL Unit. All three functions are accommodated by three separate and modular components.

Clean air is beneficial for maintaining the durability of the components and productivity of the pneumatic system. Meanwhile, controlled air contributes to improving safety and security aspects.

In the food and beverage (F&B) industry, the use of Nitrogen gas is common, especially in the packaging process.

Air Service Unit or FRL Unit is among Main Components in the Pneumatic System which has the...

Pneumatic systems are the backbone of industrial automation with many advantages. Despite its high...

Industrial power supplies are important components that contribute to providing a stable supply of...

Polyurethane (PU) hose is a pneumatic hose that has elastic, strong and high flexibility...

The electrical contactor is an important component that functions to regulate the 3-phase motor...

![Problems with 3 Phase Contactors and How to Solve Them [Practical & Effective]](https://bawalaksana.co/wp-content/uploads/2025/07/Masalah-Pada-Kontaktor-Motor-3-Phase-dan-Cara-Mengatasinya-Bawalaksana-ID-1080x675.jpg)

Entering the era of industrial automation and Digital Factory era, electrical contactors have...

Manufacturing in the modern era faces many major challenges that can threaten business resilience,...

Examples of the application and benefits of Artificial Intelligence (AI) in industrial automation...

Entering the digital era and smart industry today, data acquisition of various parameters in the...

Terminal Block technology has evolved significantly since Phoenix Contact introduced its first...