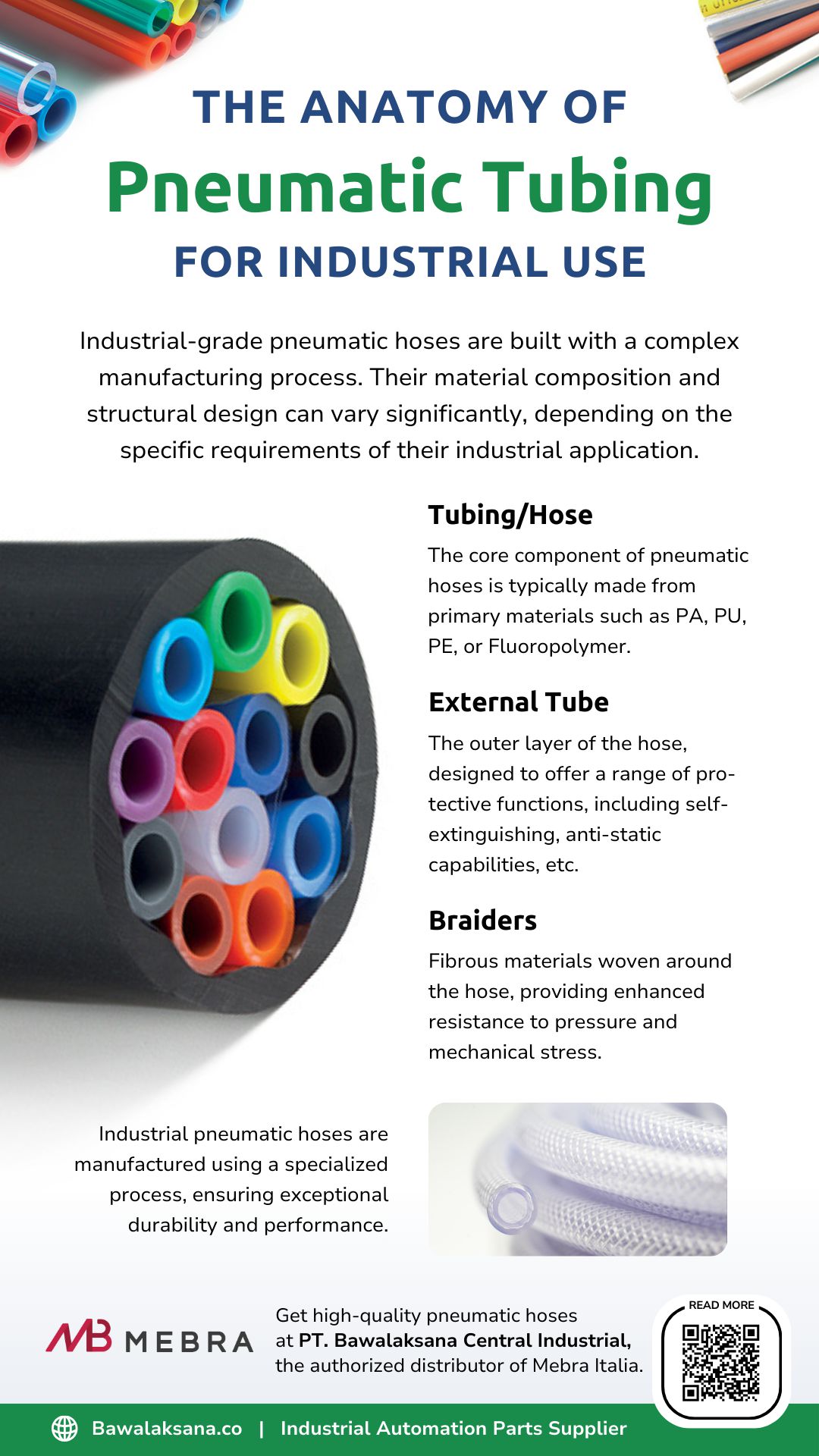

Industrial-grade pneumatic tubing has a complex structure comprising various intricate components. These components’ material composition and structure vary depending on the specific industrial application.

Pneumatic hoses or tubing undergo a specialized manufacturing process that sets them apart from conventional hoses despite potentially using similar materials.

Pneumatic tubing is a vital component of Pneumatic Systems within industrial sectors, and a comprehensive understanding of the materials and production processes associated with it is essential. This knowledge is key to recognizing the variety of industrial hoses and selecting the appropriate tubing for specific applications.

In this article, the Bawalaksana team will delve into the critical components of pneumatic tubing, the materials employed, and the manufacturing processes that yield highly durable hoses.

Components of Pneumatic Tubing

The essential components of pneumatic tubing, commonly called industrial hoses, can be classified into three primary categories: the tube or hose, the external tube, and the braiders. Below is a comprehensive examination of each component.

Tube or Hose

The tube or hose constitutes the fundamental component of the assembly and is typically manufactured from one of the following materials:

- Polyamide

- Polyethylene

- Polyurethane

- Fluoropolymer

External Tube

The external tube, also known as the outer layer of the hose, serves a critical protective function and fulfills several roles, including:

- Ensuring fire resistance through self-extinguishing properties

- Providing external protection by shielding the inner components from external factors

- Minimizing condensation to reduce moisture accumulation

- Among other functions

Braiders

Braiders are mesh-like reinforcements that encase the tubing, significantly enhancing durability and providing additional protection against pressure. Conventionally, braiders are made of textile or metal.

It is essential to acknowledge that not all variations of pneumatic or industrial hoses incorporate braiders or fiber reinforcements. Specifically, only certain types, such as Reinforced PVC hoses, utilize braiders to enhance strength and resilience.

Materials and Components of Industrial Hoses

The materials used to manufacture pneumatic hoses differ significantly from those employed in conventional or household hoses. This distinction is essential to ensure adherence to stringent industrial regulations and standards.

The selection of materials also considers the necessity for a dependable supply chain to satisfy the high demands in the industrial sector.

The following are some of the primary raw materials used in the production of pneumatic system hoses:

- Polyamide (PA)

- Polyurethane (PU)

- Polyethylene (PE)

- Fluoropolymer

Please refer to our detailed article on this subject for a comprehensive examination of the Various Types of Pneumatic Hoses and Their Functions in diverse industrial applications.

Manufacturing Process of Pneumatic Tubing and Industrial Hoses

The production of pneumatic tubing is an intricate process that integrates scientific principles and advanced technology. Before initiating the manufacturing process, a team of specialists engages in analysis, research and development (R&D), and design to ensure optimal quality outcomes.

Each phase yields critical data and insights that define the characteristics and specifications of the hose to be fabricated.

1. Analysis

During this phase, experts assess the requirements of pneumatic systems across various industries. Key considerations include:

- The necessary air pressure

- The volume and specific applications of the hose

2. Research and Development (R&D)

In the R&D phase, the manufacturing team investigates the most suitable materials for industrial hoses. This examination takes into account:

- Strength and durability

- Flexibility

- Resistance to temperature, pressure, and chemical exposure

3. Design

In the design phase, the expert team formulates the specifications for the hose, focusing on essential factors such as:

- The inner diameter of the hose

- Hose length

- Compatibility with connectors or fittings

Through these three critical stages—analysis, R&D, and design—manufacturers ensure that the resultant hoses adhere to industrial standards, regulations, and the specific requirements of end users.

The Importance of High-Durability Industrial Hoses

The diverse range of industrial air hoses is purposefully designed, with manufacturing professionals conducting comprehensive research and analysis to develop hoses that comply with specific industry standards and regulations.

Choosing the most suitable type for the intended application is imperative to ensure that the hose selected aligns with industrial specifications.

Key Considerations When Selecting a Pneumatic Hose:

- The required hose diameter for the application

- Industry-specific criteria, including resistance to temperature, pressure, or chemicals

- Relevant industry regulations (e.g., FDA, DIN, ISO)

- Application requirements, such as rigidity, flexibility, chemical resistance, and external protection

The appropriate hose selection can significantly enhance both productivity and cost efficiency. Conversely, opting for a hose that fails to meet industry standards or regulations may have substantial adverse effects.

It is strongly advisable to consult with professionals who are experts in this field to maximize the investment value in hose selection.

Pneumatic Hoses for Industrial Automation Systems

Selecting the appropriate hose for industrial applications entails more than determining the type, size, and certification; it also necessitates evaluating its durability under real-world industrial conditions.

As a discerning purchaser, it is advisable to assess the hose’s durability before making a decision. Technical specifications on paper can sometimes be misleading, mainly when the pricing appears excessively economical.

Therefore, it is essential to ensure that the pneumatic tubing or hose conforms to actual operational requirements to maintain optimal performance within automation systems.

Authorized Distributor of Mebra Plastik Pneumatic Hoses

PT. Bawalaksana Central Industrial is the official distributor of pneumatic hoses from Mebra Plastik Italia. Our products have been demonstrated to perform effectively in industrial environments and address extreme challenges.

Mebra Plastik, with its focus on innovation and high-specification products, is a trusted name in the industry, so you can be confident in your choice.

Mebra Plastik specializes in pneumatic hoses and industrial tubing, with most of its products certified to meet American, European, and other high industrial standards. With over five decades of experience in industrial tubing, Mebra Plastik has established itself as a leader in innovation and developing high-specification products.

For industrial pneumatic systems requiring superior quality high-durability tubing, we strongly recommend Mebra products for critical applications within your organization.

Enhancing Productivity with Premium Pneumatic Tubing

Utilizing premium pneumatic hoses and industrial tubing can elevate your factory’s productivity and production quality. For comprehensive product information, we invite you to engage with our professional team by clicking the consultation button below.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)