PTFE or Teflon hoses are highly heat-resistant and extensively utilized in petrochemicals, pharmaceuticals, healthcare, food and beverage, and automation systems. Due to their remarkable properties, their popularity has surged across various sectors in Indonesia.

PTFE hoses are uniquely capable of withstanding extreme conditions, making them the ideal choice for applications that demand resistance to high temperatures, corrosive chemicals, and harsh environmental factors simultaneously.

Thanks to Polytetrafluoroethylene (PTFE) or Teflon, these hoses are designed for diverse industrial and petrochemical uses. They demonstrate outstanding chemical resistance, excellent thermal stability, and low friction, which makes them perfect for transporting aggressive fluids and gases.

They also can endure significant temperatures and pressures, ensuring safe and dependable operation even in the most challenging environments.

In this article, Bawalaksana Central Industrial will explore the functions and benefits of PTFE hoses and highlight various applications across different industrial and manufacturing sectors.

When Should You Use PTFE Hoses?

PTFE (Teflon) hoses are highly recommended for industrial applications that involve simultaneous exposure to chemicals, oils, aggressive gases, and high temperatures (above 100°C).

What Pressure Can PTFE Hoses Withstand?

PTFE hoses can handle pressures ranging from 6 to 25 BAR (87–362 psi), depending on operating temperature, hose diameter, and wall thickness. However, specifications may vary between manufacturers.

Functions and Characteristics of PTFE Hoses

Polytetrafluoroethylene (PTFE) hoses are crafted from a synthetic plastic polymer and are celebrated for their outstanding properties. These hoses boast high flexibility, exceptional resistance to corrosive liquids and gases, and can endure extreme temperatures up to 200°C. Because of these remarkable features, PTFE hoses find widespread use in various industries.

Key Applications and Advantages of PTFE Hoses

PTFE hoses are commonly employed in a range of industrial applications, including:

- Transfer of chemical and petroleum products

- Steam applications within the chemical sector

- Air suspension and braking systems

- Pneumatic systems in the food and beverage industry

- Vacuum-related applications

PTFE hoses are an excellent option when selecting the correct hoses for your needs. Here’s why they’re becoming increasingly popular:

- High-temperature resistance: They perform effectively at temperatures up to 200°C, making them perfect for hot fluid applications and providing reassurance about their performance in extreme conditions.

- Chemical resistance: Due to PTFE’s inert characteristic, these hoses withstand strong acids, bases, solvents, and other aggressive chemicals.

- Corrosion resistance: Their non-reactive characteristics prevent degradation when exposed to corrosive substances, ensuring long-lasting durability.

- Low friction coefficient: The non-stick surface minimizes residue buildup, allowing smooth fluid flow throughout the hose.

- Low permeability: PTFE hoses effectively stop gas, chemicals, or oil from leaking through the hose walls, reducing the risk of hazardous spills.

- Good flexibility: While they may not be as elastic as polyurethane (PU) hoses, PTFE hoses still provide a minimum bending radius of 11–250 mm, depending on their diameter.

- FDA Approved: Many PTFE hoses are FDA-certified, making them suitable for use in the pharmaceutical, medical, and food and beverage sectors.

- Self-extinguishing: These hoses have a crucial safety feature; they extinguish flames automatically once the ignition source is removed.

With their exceptional blend of features, PTFE hoses offer a wide range of options for various industrial applications. Their versatility and durability ensure they can handle even the most challenging demands, giving you peace of mind for all your operational needs.

Considerations When Choosing PTFE Hoses

While PTFE hoses offer numerous benefits, they also come with some notable downsides:

- Environmental Impact: The waste generated from manufacturing and recycling PTFE is challenging and costly.

- Economic Factors: PTFE hoses’ superior performance comes with a higher price tag than other materials on the market.

Top Alternatives to PTFE Hoses

If PTFE hoses don’t quite meet your requirements, consider these two high-performance alternatives:

- PFA (Perfluoroalcox) Tubing: This option delivers performance on par with PTFE and can handle hot chemical transfers up to 260°C. It also boasts UL94 V0 self-extinguishing properties, adding an extra layer of safety.

- Semi-Rigid Perfluoroalcox (FEP) Tubing: This more budget-friendly choice is designed for applications that require chemical and heat resistance. It withstands heat, UV exposure, and wear while being UL94 V0 self-extinguishing and chemically inert to most industrial substances.

Businesses can decide which is best for their specific industrial and operational needs by weighing the advantages, limitations, and alternatives to PTFE hoses.

Safety Factor of PTFE Hoses

Typically, pneumatic hoses possess a safety factor ranging from 3:1 to 4:1 for their working pressure at a temperature of 23°C.

This means these hoses can crack or rupture if the pressure exceeds three to four times their recommended maximum working pressure at that temperature.

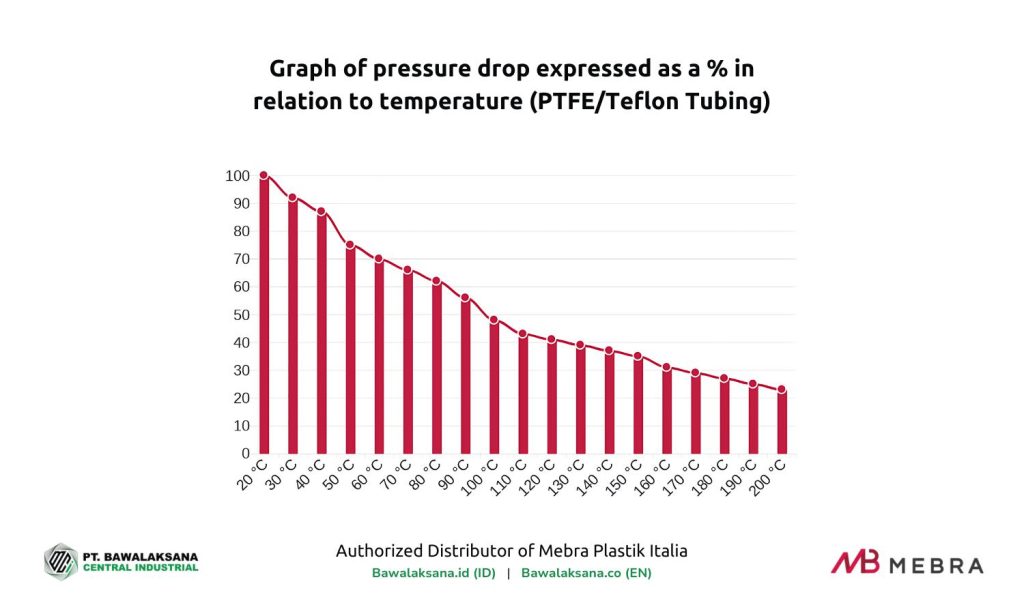

As the operating temperature rises, the maximum working pressure decreases correspondingly. It’s crucial to understand that working pressure can vary between different hose types, which is illustrated in specific performance graphs.

For detailed information, you should consult the manufacturer’s guidelines for industrial tubing.

The graph above is an example of a pressure drop chart for Teflon (PTFE) hoses from Mebra Plastik Italia, a specialist in industrial tubing.

This data shows that while Teflon hoses can function at temperatures up to 200°C, this capability comes with a reduction in working pressure. The higher the temperature, the lower the pressure resistance of the hose.

The graph indicates that the maximum pressure at 200°C is roughly 1.2 BAR (17 Psi), considering a safety factor 3:1.

Please avoid subjecting the hose to double the recommended pressure limit, as this could significantly reduce its lifespan or even cause it to burst. (Read: 6 Common Causes of Pneumatic Hose Failure and How to Prevent Them)

In the following section, we’ll explore various applications of Polytetrafluoroethylene (PTFE) hoses in industrial settings.

Applications of PTFE Hoses Across Various Industries

Having explored the functions and benefits of PTFE (Teflon) hoses, let’s take a look at some key applications in different industries where they play a vital role:

Chemical Industry

In the chemical sector, Polytetrafluoroethylene (PTFE) hoses are indispensable due to their exceptional resistance to aggressive and corrosive substances.

Examples of PTFE Hose Uses in the Chemical Industry:

- Transporting Aggressive Chemicals: PTFE hoses are crucial for the safe transfer of acids, bases, and solvents. Their corrosion-resistant properties ensure the entire system’s integrity, preventing contamination and leaks.

- Chemical Processing Operations: These hoses help maintain a reliable and secure flow of fluids, even under extreme temperature variations, which is essential for safe chemical processing.

- Laboratory Applications: PTFE hoses are ideal for transporting samples, reagents, and highly reactive chemicals, ensuring contamination is avoided throughout the process.

- Petrochemical Industry: In this sector, PTFE hoses are commonly used for transferring fuels, lubricants, and other chemical products that demand high resistance to heat and chemicals.

Industries can enhance safety and efficiency by employing PTFE hoses, making them key components in various processes.

Pharmaceutical and Medical Industry

The pharmaceutical industry is crucial in developing and producing medicines, vaccines, and health supplements. Within this sector, hoses must be heat—and chemical-resistant while adhering to strict FDA-approved hygiene standards.

Teflon hoses emerge as the perfect solution to meet these demands. Constructed from PTFE material, they guarantee high-quality, hygienic, and sterile production processes.

Advantages of Teflon Hoses in the Pharmaceutical and Medical Fields:

- Pharmaceutical Processing: Teflon hoses find application in various phases, from mixing and filling to packaging. Their inert and hygienic characteristics help avoid contamination and uphold the integrity of pharmaceutical products.

- Piping Systems: These hoses effectively transport liquids, suspensions, and solutions, all while ensuring hygienic conditions are maintained.

- Sterilization Processes: PTFE hoses can withstand high-temperature sterilization methods, including autoclaving.

- Vaccine Production: In vaccine manufacturing, PTFE hoses are vital for transferring raw materials, culture media, and finished products. Their inert nature prevents any interactions that could threaten the integrity and purity of vaccines.

- Health Supplement Industry: The Teflon hoses help transfer active ingredients, herbal extracts, and liquid formulations while preserving product quality.

Overall, Teflon hoses are indispensable in the pharmaceutical and medical sectors, ensuring safety and efficacy in every process.

Food and Beverage (F&B) Industry

In the F&B industry, PTFE hoses are vital due to their outstanding durability. Food and beverage production often involves high temperatures, continuous operations, and routine sterilization equipment. Teflon hoses effectively meet these challenges with flexibility, FDA approval, hygienic properties, and long service life.

Key Roles of PTFE (Teflon) Hoses in the F&B Industry:

- Food Processing: PTFE hoses are utilized to transport compressed air, food additives, coloring agents, and other ingredients across a range of temperatures. Their non-reactive nature helps prevent contamination and guarantees product quality, even under intense heat.

- Pasteurization and Sterilization Systems: These hoses play a vital role in various pasteurization and sterilization processes for food and beverage products, ensuring safety without compromising the integrity of the product or the hose itself.

Automotive Industry

Teflon hoses are extensively utilized in the automotive sector and are prized for their resistance to high temperatures and oils. Here are some of the primary applications of PTFE hoses within the automotive industry:

- Fuel System: PTFE hoses are used to transport gasoline, diesel, and various fuels. Their robust chemical, oil, and heat resistance guarantees a safe, leak-free fuel delivery.

- Braking System: These hoses are crucial in transferring brake fluid securely, even under extreme temperatures. Teflon brake hoses typically feature an external protective layer for added durability.

- Lubrication System: Thanks to their exceptional resistance to heat and oil, PTFE hoses are ideally suited for distributing lubricants in vehicles.

- Cooling System: Lightweight yet durable, Teflon hoses effectively carry coolant fluids within automotive cooling systems.

- Pneumatic System: PTFE hoses are commonly used in air suspension and braking systems that rely on compressed air. Additionally, Rilsan® PA 11 PHL is a strong alternative for vehicle pneumatics.

These examples illustrate just a few of the diverse applications for Teflon hoses in various industrial and manufacturing fields.

Since PTFE hose specifications can differ among manufacturers, we strongly advise consulting with our expert team before choosing a hose for your specific needs. Therefore, you can decide the proper specifications tailored to your operational requirements.

Official Distributor of Teflon® (PTFE) Hoses

If you’re exploring the many benefits of Polytetrafluoroethylene (PTFE) hoses, commonly referred to as Teflon® hoses, you might be curious about where to find a reliable distributor for these products.

PT. Bawalaksana Central Industrial proudly serves as the official distributor for Mebra Plastik Italia, a renowned manufacturer specializing in PTFE hoses and pneumatic tubing.

With over 50 years of experience, Mebra Plastik Italia, based in Italy, is trusted by industries worldwide for its commitment to high-quality and durable products.

We provide a diverse selection of Teflon® hoses in various sizes and types, including fluoropolymer options such as:

- Flexible Perfluoroalcox (PFA): Operating temperature: -60°C to 260°C

- Semi-rigid Perfluoroalcox (FEP): Operating temperature: -60°C to 200°C

- Kynar Flex® 2800: Operating temperature: -40°C to 90°C

- Kynar® PVDF HD 4000 Operating temperature: -40°C to 100°C

If you want more information about our fluoropolymer hoses and other tubing solutions from Mebra Plastik Italia, don’t hesitate to contact our Sales Engineers.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)