Pneumatic hoses are often overlooked, yet they are essential components in pneumatic systems. Many companies use low-quality hoses, which can jeopardize the functioning of complex and critical industrial automation setups.

Using inferior pneumatic hoses can lead to serious consequences, including product contamination, escalating maintenance costs, and potentially severe production halts. These outcomes underscore the critical role of high-quality hoses in industrial automation systems and highlight the potential risks of using low-quality hoses.

As you may know, a pneumatic hose’s primary function is to transport compressed air from the compressor to various system parts, including the air service unit, solenoid valves, and pneumatic cylinders. In this context, pneumatic tubing can be considered the system’s “lifeline,” underscoring its critical role in operation.

Can you imagine the consequences of a component so vital being susceptible to failure? Such issues could result in:

- Energy waste and reduced efficiency

- Frustrating downtime

- System failure that brings production lines to a standstill

- Significant financial losses due to unmet production goals

Pneumatic hoses’ role in air distribution throughout the system cannot be underestimated. Understanding just how critical these hoses are, the Bawalaksana Central Industrial team strives to offer a comprehensive guide on selecting the best pneumatic hose for your industrial automation systems.

The Importance of Choosing the Right Pneumatic Hose

Selecting the appropriate pneumatic hose is crucial for any industrial operation. Unlike standard hoses, industrial-grade pneumatic hoses boast a more intricate structure and composition that significantly affects their durability, even if made from the same materials.

Thanks to advancements in manufacturing technology, even everyday plastic can be crafted into high-quality hoses. Therefore, when choosing the right pneumatic hose for your automation system, it’s essential to approach the decision carefully. Adopting a mindset of “as long as it works, it’s fine” can lead to serious pitfalls in an industrial setting.

Pneumatic hoses are vital in ensuring your entire automation system’s smooth operation and efficiency. Their reliability also impacts your business’s reputation and long-term viability, underscoring their importance and value in the system.

Key Factors to Consider When Choosing a Pneumatic Hose

Several key factors should be considered when choosing a pneumatic hose. These factors can help guide your decision-making and ensure you select the right hose for your industrial automation system.

Selecting the proper pneumatic hose for your industrial automation system can often be lengthy and challenging. You’ve likely already taken several necessary steps, such as:

- Seeking recommendations from your engineering team

- Reviewing product specifications and aligning them with your on-site needs

- Confirming the validity of product certifications and ensuring the specifications match what you’re seeing

- Conducting hose tests to guarantee compatibility with working pressure, temperature, and chemical agents

- Comparing prices among various vendors

The good news is that all your efforts will ultimately lead you to a trustworthy and reliable supplier.

If you’re currently navigating this journey, we’re here to help simplify the process and make it more enjoyable. Below are several key mindsets to adopt as you search for and select the ideal pneumatic hose for your company’s automation system.

Meets International Standards

The role of pneumatic hoses in industrial automation systems is crucial, so your selection must be discerning. Compliance with international standards is key when choosing a high-quality pneumatic hose.

Why does this matter?

Ensuring your hose meets these standards gives you confidence that it has been validated for specific applications. For instance, pneumatic tubing certified under FDA Title 21 can be utilized in pneumatic systems within the food, beverage, and pharmaceutical sectors.

Similarly, hoses that comply with CE Reg. 10/2011 according to European regulations guarantee that no harmful substances will leach into food and that there will be no adverse reactions to food products.

This means that when these pneumatic hoses come into direct contact with food or beverages, they won’t cause contamination. Consequently, the integrity and quality of your food products are maintained.

Here are several key certifications for pneumatic hoses that meet international standards:

Food & Beverage Industry

For pneumatic hoses utilized in the food and beverage sector, the following certifications are essential:

- CE Reg. 10/2011

- CE Reg. 1935/2004

- D.M. 21/03/73

- FDA Title 21

Automotive Industry

In the automotive sector, particularly for vehicles equipped with air brake systems, such as container trucks, buses, and trains, the relevant certifications include:

- ISO 7628:2010

- DIN 74324

- DIN 73378

Mining Industry

When it comes to pneumatic hoses in the mining and petrochemical industries, the certifications you should be aware of are:

- ISO 8031:2009(E)

- ATEX

General and Manufacturing Industry

For applications in the general and manufacturing industries, particularly where exposure to welding slag and flames occurs, the following certifications are crucial:

- UL94 V2/V0

These examples illustrate the importance of adhering to international standard certifications for pneumatic hoses. Choosing the right hoses according to specific application standards ensures your pneumatic system runs smoothly while maintaining the highest safety, reliability, and quality levels.

Harnessing the Power of Top-Quality Polymer Hoses

As previously noted, engineers can produce pneumatic hoses from the same fundamental materials utilized in conventional hoses. However, due to advancements in manufacturing engineering, engineers can now create exceptional pneumatic hoses from standard polymer materials.

A good example of this is a non-DEHP pneumatic hose, Crystal PVC. While it is constructed from Polyvinyl Chloride (PVC), it isn’t the same as or comparable to cheaper PVC hoses. The Crystal PVC hose is free from DEHP and other phthalates—chemicals that may leach into food and pose potential health risks.

Another great example is Linear Low-Density Polyethylene (LLDPE) pneumatic hoses. Although this hose originates from the familiar PE material, its quality significantly surpasses standard PE hoses. This PE hose presents numerous benefits, particularly for the food and beverage industry, as it meets FDA standards, boasts excellent tensile and burst resistance (ESCR), is UV-resistant, and is non-reactive with food products.

When you consider these advantages, the potential gains for your company become clear, including enhanced productivity, improved product quality, and greater competitiveness in a rapidly evolving market.

Opting for hoses made from high-quality polymer materials will elevate your operations and contribute to a healthier and more sustainable industry. This is particularly true in sectors like food and beverage manufacturing, where strict regulations and ethical standards are crucial.

Compliance with Relevant Regulations

Each industrial sector operates under specific regulations to safeguard the environment and promote long-term sustainability. Among the most heavily regulated industries are food and beverage (F&B) and pharmaceuticals. These sectors are subject to various rules and standards due to their direct impact on consumer products and public safety.

The regulations stipulate several vital requirements for pneumatic hoses used in these industries. The hoses must not:

- Release harmful substances into food

- Alter the composition, taste, or odor of the food in unacceptable ways

- React negatively to food, ensuring safety for direct contact with consumables

- contains DEHP (Di-(2-ethylhexyl) phthalate), which poses significant health risks

Companies must be very discerning in selecting pneumatic hoses for their industrial automation systems to meet these stringent regulations. However, finding hoses that comply with all regulations and boast durable performance is challenging.

This challenge is particularly pronounced in the F&B and pharmaceutical sectors, which often have critical operational hurdles. Sourcing hoses that can handle extreme conditions and environments—such as repeated sterilization, high temperatures, or chemical exposure—proves difficult.

When the Bawalaksana team wrote this article, options for pneumatic hoses that satisfy rigorous regulatory standards and the demands of harsh field conditions remained limited. The interplay of these factors often leads to a shortened hose service life; if a hose is of subpar quality, it may wear out quickly, resulting in frequent system downtime.

Moreover, companies must be vigilant about potential risks. Some hose materials may degrade at high temperatures or react with specific chemicals, potentially contaminating the final product. Such incidents can compromise product quality and, in some instances, pose serious health hazards.

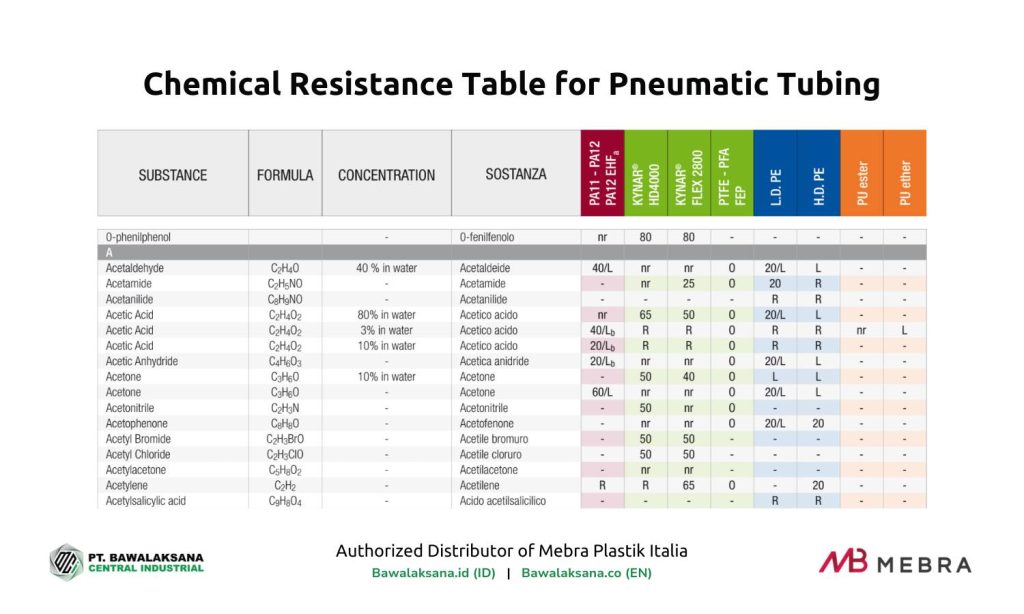

When working in critical sectors such as pharmaceuticals, biotechnology, and petrochemicals, it’s essential to scrutinize the Chemical Resistance Table. Doing so will allow you to clearly understand how various chemical reactions and their effects will influence the performance of the pneumatic tubing you intend to use.

Safety Factor on Working Pressure

A critical aspect often overlooked when dealing with pneumatic hoses is the Safety Factor related to Working Pressure. This factor is closely tied to two main parameters: working pressure and operating temperature.

For industrial-grade pneumatic tubing, the typical Safety Factor is either 3:1 or 4:1, assuming an operating temperature of 23°C. This indicates that the hose might burst or rupture if it reaches three to four times the maximum recommended pressure under those specific temperature conditions.

It’s important to note that as the operating temperature increases, the maximum working pressure the hose can safely withstand decreases.

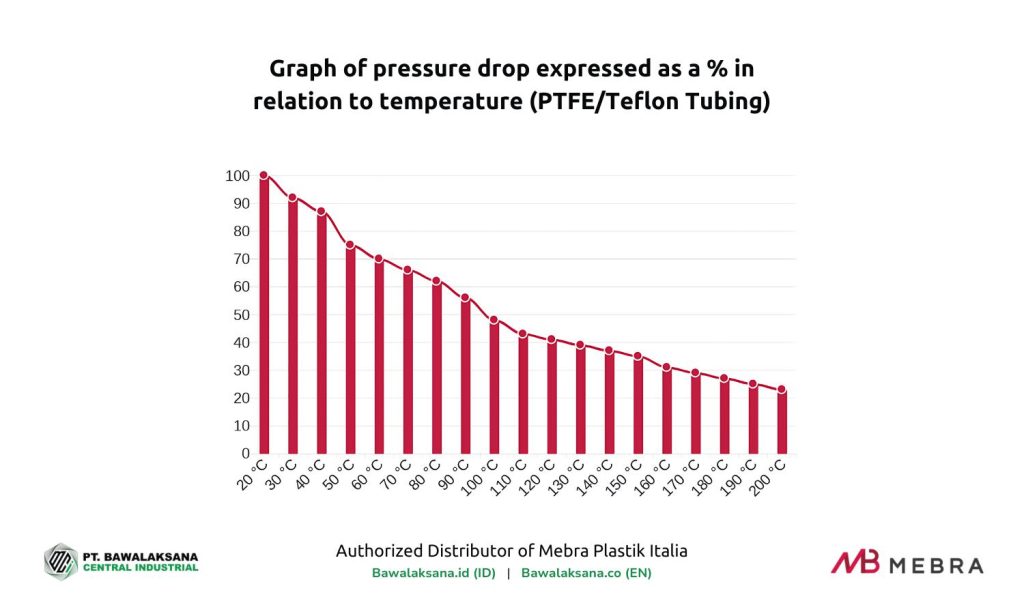

Improperly adjusting system pressure with the recommended working pressure is a frequent cause of hose failure. The Graph of Pressure Drop illustrates how hose performance diminishes as operating temperatures rise.

Sudden ruptures can result in system failures or unplanned downtime, significantly increasing production costs. For instance, the diagram below illustrates the Graph of Pressure Drop for PTFE (Teflon) hoses produced by Mebra Plastik Italia.

According to the graph above, the pressure resistance of PTFE hoses significantly decreases as the operating temperature approaches 200°C. At this temperature, the recommended working pressure for Teflon hoses is just 20% of their maximum pressure.

For instance, if a 2×4 mm Teflon hose can handle a maximum pressure rating of 24 BAR at 23°C, its recommended working pressure at 200°C would be 20% of 24 BAR. It translates to a recommended maximum pressure of 4.8 BAR, or roughly 69.6 PSI.

Considering that the Safety Factor on Working Pressure for PTFE hoses is 3:1, the hose could rupture if the pressure reaches three times 4.8 BAR, as indicated by the graph. This information is crucial for ensuring your pneumatic hose is durable and prolongs its service life. It’s highly advisable to avoid working pressures that exceed two to three times the recommended pressure.

Remember that the Safety Factor and the Pressure Drop Graph can differ between hose types. For precise pressure recommendations, always consult the manufacturer of the industrial tubing.

Hose Material Compatibility with Operating Media and Work Environment

The compatibility of hose materials plays a crucial role in the success of a pneumatic system and in achieving desired productivity levels. When choosing the right pneumatic hose for your industrial automation setup, it’s essential to consider two main factors:

- Operating Media: This refers to the type of fluid that will flow through the hose, which could include corrosive gases, oils, greases, high-temperature chemicals, food substances, and more.

- Work Environment: Consider the external conditions that can impact the pneumatic hose’s performance, such as extreme temperatures, UV exposure, corrosive chemicals, moisture, sparks, dust, static electricity (especially in ATEX environments), and even pests like rodents.

By carefully selecting pneumatic tubing that aligns with the operating media and the environmental conditions, you can ensure that your system operates at its best.

Additionally, this thoughtful approach to selection can lead to lower maintenance costs, as a well-suited hose will be more durable against weathering, UV damage, cracking, or leaks caused by various external influences.

Remembering that pneumatic systems often operate in unpredictable work environments is crucial. As a result, selecting the correct type of hose based on the specific requirements is essential. Here are some key considerations:

- Complex Work Environments: When you face challenges like high humidity, UV exposure, abrasion, and flexibility, opt for a Polyurethane (PU) hose. This type of hose offers advantages such as hardness of 52 Shore D and excellent hydrolysis and UV resistance, like the PU Clear 1198 UV Resistance tubing.

- Food & Beverage or Pharmaceutical Sectors: For environments with extreme conditions, like high temperatures and chemicals, and stringent hygiene requirements, choose heat—and chemical-resistant hoses that comply with international standards. PFA (Perfluoroalkoxy) tubing is a solid choice for these applications.

- Spark and Fire-Prone Areas: In settings where sparks or welding slag are common or fire risk, it’s best to use hoses with self-extinguishing properties, such as those meeting UL94 standards. Hoses with multilayer construction, like Anti-Spatter Tubing, are ideal.

- Gas Processing Applications: When working in methane or hydrogen gas processing or in environments where sparks from dust and friction may occur, opt for antistatic pneumatic hoses, such as Polyurethane 98 Antistatic hoses.

- Automotive Sector: For air braking or lubrication in the automotive industry, where exposure to moisture and chemicals is a concern, choose rigid and robust pneumatic hoses, like the PA 12 HL Rigid High Resistance hoses.

- Powder Coating Applications: In powder coating scenarios, particularly in automotive manufacturing and industrial robot use, select hoses known for their abrasion resistance, moisture resistance, and flexibility, such as PU 1185 High-Flexibility hoses.

These examples illustrate how to choose the proper industrial hose based on the media and environment. The more complex the challenges you face, the more specific your choice of hose needs to be. This way, you can confidently utilize pneumatic hoses even in the most demanding applications.

Fortunately, a wide range of pneumatic hoses and industrial tubing is available to tackle the challenges on the ground. Contact our expert team for tailored recommendations that meet your needs.

Choosing the Right Pneumatic Hose for Your Industry

Selecting the appropriate pneumatic hose for automation systems in critical industrial sectors. To guide your decision, here are some key factors to keep in mind, each playing a crucial role in the success of your pneumatic system.

- Operating Media: Hoses must be selected based on the type of fluid they’ll carry—whether that’s air, corrosive substances, oil, grease, granules, powder paint, or even food and beverage materials.

- Work Environment: Consider the conditions under which you use the hose. Is it in a controlled environment, a high-humidity setting, exposed to UV rays, chemicals, ATEX zones, or areas where sparks may occur?

- Working Pressure: Ensure the hose’s diameter and working pressure align with the hose specifications, taking into account the Safety Factor for Working Pressure and the Pressure Drop Graph.

- Rigidity/Flexibility: Different applications require unique hose characteristics. For instance, a rigid hose might be necessary for high-pressure scenarios with substantial mechanical friction, whereas highly flexible hoses are ideal for high movement/mobility applications.

- Recommended Fittings: Choosing the correct type of pneumatic fittings ensures secure connections. You must match every pneumatic hose with fittings corresponding to its specific attributes.

- Hose Length: Ensure the hose length is proportional to your pneumatic system’s needs. A hose that’s too short may put undue stress on the system, leading to breaks or damage, while an excessively long hose can result in significant pressure drops.

These considerations form the foundation for selecting the proper pneumatic hose for your company’s automation system. You can confidently make an informed choice by combining knowledgeable insights with a clear understanding of the technical elements involved.

Ultimately, each industry has unique hose requirements, and making the right selection is key to achieving optimal efficiency in your pneumatic systems.

PT Bawalaksana Central Industrial is a recognized distributor of industrial tubing from Mebra Plastik Italia and modern automation system components from Metal Work Pneumatic. We deliver a wide range of comprehensive solutions tailored for various pneumatic automation system applications, all in adherence to international standards.

Mebra Plastik Italy’s industrial tubing comes in an extensive selection designed to meet the needs of critical industries, with applications that include:

- Compressed air and vacuum systems for pneumatics

- ATEX-approved environments, addressing static electricity concerns

- Welding areas where sparking risks are present

- Transporting oils, greases, and lubricants

- Steam applications in petrochemical and power plants

- Transfer of chemicals or corrosive gases

- Food-safe and potable water uses

- Disinfestation processes

- Nebulization techniques

- Air shafts

- Clutch mechanisms

- Powder paint applications

- Industrial automation tasks

- Loading raw material granules

- Cable protection for energy chains and carriers

- And much more

To ensure the best results, our engineering team strongly recommends conducting thorough research and analysis before you decide to purchase industrial tubing or pneumatic hoses.

Feel free to request samples from the vendor’s official distributor if needed. This approach will help you secure high-quality hoses for critical applications within your company.

As we all know, today’s manufacturing landscape emphasizes high productivity, mobility, and optimal energy efficiency for pneumatic systems. This shift necessitates a more discerning selection of spare parts for industrial automation systems, including pneumatic hoses.

By making careful choices, you can enhance compliance with regulations, improve cost efficiency, and sustainably boost productivity.

Utilizing top-quality hoses alongside high-efficiency automation systems will enable your operations to run smoothly and effectively, paving the way for a seamless transition into the intelligent and modern era of Industry 5.0.

You’ve come to the right place if you plan to implement an advanced pneumatic system to drive productivity and efficiency. PT. Bawalaksana Central Industrial is here to help you implement a modern pneumatic system or upgrade to your company’s latest pneumatic automation technologies.

Don’t hesitate to consult our Sales Engineering team for the best recommendations tailored to your needs. Click the consultation button below to start a conversation with our experts.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)