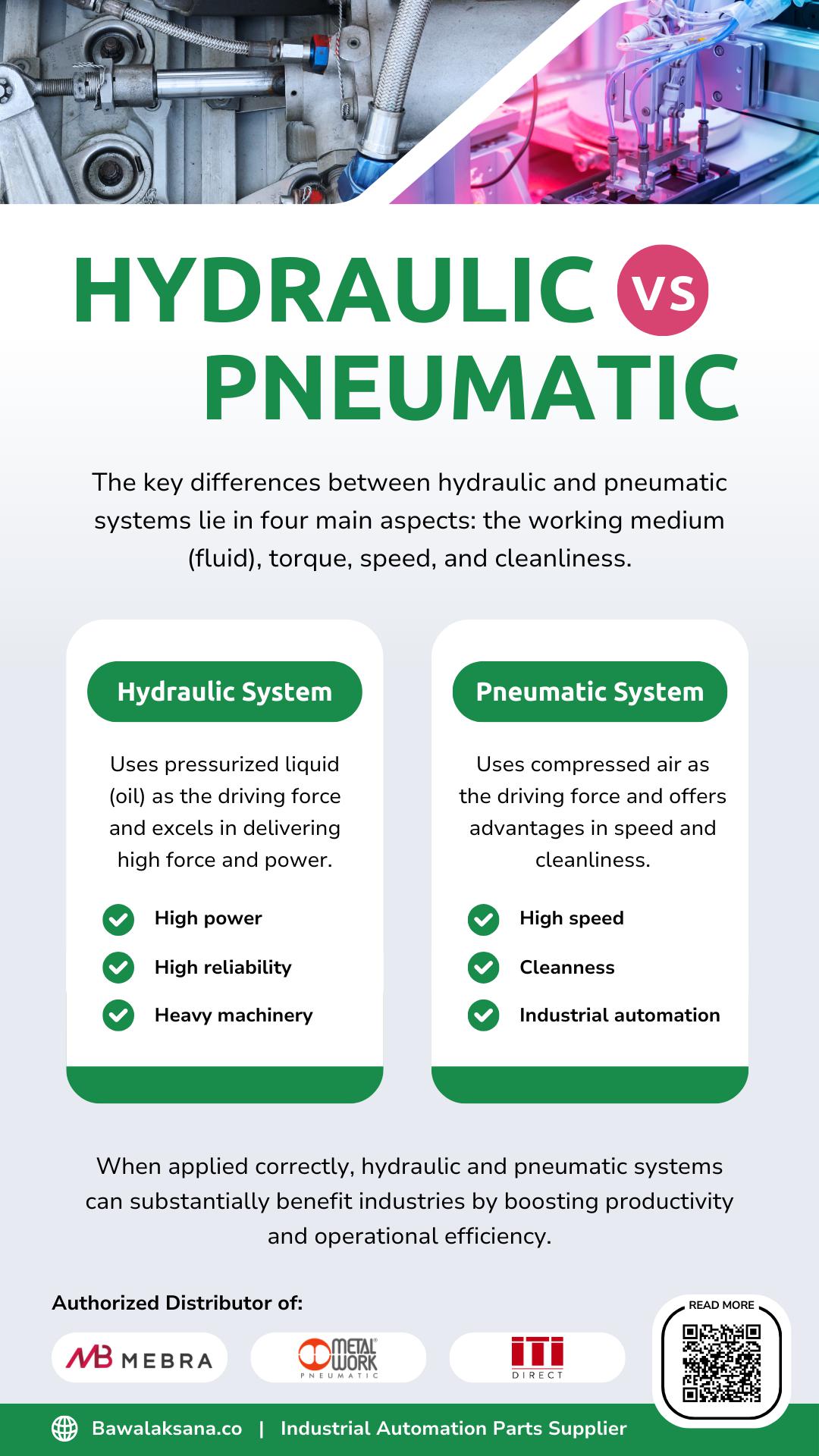

Hydraulic and pneumatic systems are distinct in several key areas, including their working media, torque (force) output, speed, and cleanliness. The primary difference lies in their medium: hydraulic systems operate with liquids, while pneumatic systems rely on compressed air or gas.

Both systems have advantages and drawbacks. Therefore, if your company is considering adopting one of these systems, it’s crucial to consider various factors, which we will explore in this article.

In our previous piece, we delved into The Advantages and Disadvantages of Pneumatic Systems for Industrial Automation. This article aims to compare pneumatic and hydraulic systems broadly.

Understanding the fundamental differences between these two systems is crucial—it’s empowering. This knowledge can significantly benefit both the industrial and commercial sectors. By grasping these distinctions, engineers can enhance functionality and reduce risks, ultimately promoting long-term sustainability in industrial practices.

The key points we’ll cover in this article include:

- The main differences between hydraulic and pneumatic systems

- The underlying principles of each system

- Components found in pneumatic and hydraulic systems

- Force and speed capabilities

- Cleanliness and sustainability considerations

- Factors to weigh when selecting between pneumatic and hydraulic systems

Let’s dive into a thorough comparison of pneumatic and hydraulic systems. This practical information will save time and equip you with the knowledge to make informed decisions.

What Are the Main Differences Between Hydraulic and Pneumatic Systems?

Hydraulic and pneumatic systems differ primarily in four key areas: the fluid they use, the torque they generate, their speed, and their cleanliness.

Pneumatic systems utilize compressed air as their driving force, making them well-known for their speed and precision. These systems are particularly effective for lighter, repetitive tasks that require quick operation.

In contrast, hydraulic systems use liquids like oil to generate power. They deliver greater torque, though this often comes with lower speed and less accuracy. As a result, hydraulic systems are commonly employed in heavy-duty applications that require substantial power.

| Aspect | Hydraulic System | Pneumatic System |

| Type of Fluids | Oli | Air |

| Force / Torque | Very High | Low |

| Speed | Slower | Faster |

| Cleanliness | Prone to Contamination | Clean and Contaminant-Free |

Hydraulic and pneumatic systems have notable differences in complexity. In industrial settings, hydraulic systems typically require a more significant upfront investment and come with bulkier equipment. In contrast, pneumatic systems offer greater flexibility for various applications, generally at lower costs and with lighter machinery.

Pneumatic systems can handle tasks ranging from opening and closing doors and operating pressing machines to more intricate applications such as pharmaceutical blister packaging and filling systems. They also play a crucial role in modern industrial automation, incorporating cutting-edge technologies and the Industrial Internet of Things (IIoT).

One of the standout features of pneumatic technology is its cleanliness, making it a perfect choice for environments with strict hygiene standards. This reliability is why pneumatic systems are widely used in food and beverage manufacturing, pharmaceuticals, and semiconductor industries.

However, it’s worth noting that in some sectors, a combination of hydraulic and pneumatic systems is often used to maximize efficiency. When adequately implemented, both systems can yield significant benefits for industrial and manufacturing operations.

The following section will delve deeper into the distinctions between pneumatic and hydraulic systems.

Essential Principles of Hydraulic and Pneumatic Systems

Both hydraulic and pneumatic systems are grounded in the same principle of physics: Pascal’s Law. This law states that any pressure applied to a fluid within a closed system is transmitted uniformly in all directions.

In a pneumatic system, air pressure is generated by a compressor and then conveyed to pneumatic cylinders or air-powered tools through pipes or hoses. On the other hand, hydraulic systems rely on a hydraulic pump to generate pressure, which is then directed to actuators via hydraulic pipes or hoses.

Pascal’s Law states that any pressure applied to a fluid within a closed system is transmitted uniformly in all directions. This principle is the basis for the operation of both hydraulic and pneumatic systems, allowing for the transmission of force and motion in these systems.

Components of Hydraulic and Pneumatic Systems

Hydraulic and pneumatic systems have distinctly different components, mainly because of the variations in the density of their working fluids. In this section, we will examine several essential components found in both systems and their respective functions.

Hydraulic System Components

The complexity of the devices and components in a hydraulic system varies based on your specific application needs. Here are some essential components typically found in hydraulic systems:

- Hydraulic Oil

Hydraulic oil is the working medium within these systems, enabling them to function and generate movement. It also acts as the driving force that transmits torque to the actuator, allowing it to lift heavy loads effectively.

- Hydraulic Pump

The hydraulic pump is essential for generating pressure in the working medium, typically oil, and distributing it throughout the system where needed. It draws oil from a reservoir and pushes it into the hydraulic circuit.

In essence, the hydraulic pump transforms mechanical energy from the motor into hydraulic energy as pressurized fluid. This pressurized fluid drives hydraulic actuators, allowing them to carry out various mechanical tasks like lifting, pushing, pulling, or rotating loads.

After the oil has circulated through the hydraulic system to power the actuator, it returns to the reservoir for reuse. This cycle continues seamlessly as long as the system is in operation.

- Reservoir Tank

The reservoir serves as a storage tank for hydraulic fluid, accommodating fluctuations in volume as the system operates. When the fluid heats up, it expands, and the reservoir is designed to handle these changes, ensuring smooth functioning without causing disruptions or damage to the overall system.

Inside the reservoir, a filter unit eliminates dirt and contaminants, keeping the hydraulic fluid clean. This filtration is crucial for preventing corrosion or wear on hydraulic components.

It’s worth mentioning that the fluid volume in the reservoir remains relatively stable as long as there are no leaks. The same fluid circulates through the system continuously and is not discarded as long as it stays in good condition. This contrasts with pneumatic systems, where the air used is released instead of stored in an air reservoir tank. In those systems, the air compressor draws fresh air from the environment, storing it in the air tank for the next cycle.

- Accumulator

An accumulator is a crucial device in hydraulic systems, designed to balance force and pressure. It plays a key role in stabilizing fluid pressure, ensuring the system remains responsive when needed.

When the oil pressure surpasses a specified threshold, the accumulator collects the excess fluid delivered by the hydraulic pump. This stored oil can then be released whenever the system demands a quick surge in pressure or flow.

Additionally, the accumulator dampens pressure fluctuations and vibrations generated by the hydraulic system. This helps maintain smooth and responsive operation while safeguarding essential components from potential damage.

- Hydraulic Actuator

A hydraulic actuator is crucial in transforming hydraulic energy into mechanical motion, whether linear or rotational. The energy source for these actuators is the pump, which supplies pressurized fluid (typically oil) from a reservoir.

Hydraulic actuators are well-suited for tasks requiring significant torque to lift or push heavy loads. Their impressive power is driven by fluid pressures ranging from 1,000 to 5,000 PSI (69–344 BAR).

Actuators can generally be categorized into three main types based on their power source: electric, hydraulic, and pneumatic. Our earlier article, What Is an Actuator and Its Types, thoroughly discussed this classification.

Pneumatic System Components

Pneumatic systems offer a highly efficient and cost-effective solution for applications requiring mechanical motion, whether linear or rotary. This technology is extensively used in various industries, including food and beverage, pharmaceuticals, petrochemicals, packaging, toy manufacturing (think LEGO), and more.

Here are some essential components commonly found in pneumatic systems:

- Air Compressor

The air compressor plays a crucial role by drawing in ambient air and compressing it into pressurized air. Once the air is compressed, it gets stored in an air reservoir tank for use in the pneumatic system.

- Air Reservoir

In contrast to hydraulic systems, the air reservoir in a pneumatic setup is designed to store pressurized air, serving as a vital energy reserve. Additionally, it plays a key role in minimizing pressure fluctuations within the system, which helps ensure smooth and stable operation.

- Air Service Unit (FRL)

The FRL unit, which stands for Filter, Regulator, and Lubricator, plays a vital role in any pneumatic system by carrying out key functions:

- Filter: It eliminates moisture and contaminants, ensuring the air is clean and dry.

- Regulator: It keeps air pressure stable and within the required range for optimal performance.

- Lubricator: It introduces a fine oil mist into the airflow, providing necessary lubrication for internal components.

Several FRL variants are available, tailored to meet the needs of different industries and specific applications.

- Solenoid Valve

Solenoid valves are crucial in managing pneumatic cylinders’ movement, extending or retracting their position. They can be operated manually through switches and hand levers or function automatically when connected to EB80 Valve Islands and PLCs (Programmable Logic Controllers).

- Pneumatic Hoses

Pneumatic hoses are crucial for transporting pressurized air from the air reservoir, through the FRL unit and solenoid valves, to the pneumatic actuators. They are essential for ensuring system stability and reliability.

To keep everything running smoothly, operators must regularly inspect hoses for any signs of damage or wear. Selecting the proper hose for your specific application is key to adhering to industry standards and enhancing overall system safety.

- Fittings

Fittings act as essential connectors in a pneumatic system, linking various components while effectively preventing air leaks. They simplify the secure attachment of hoses to the FRL unit, solenoid valves, and pneumatic actuators, ensuring a smooth and leak-free assembly process.

- Pneumatic Actuator

The pneumatic actuator, or pneumatic cylinder, is the endpoint of a pneumatic system. Its primary function is to transform pressurized air into mechanical motion, which can be linear or rotary.

Pneumatic actuators are well-suited for applications requiring high speed, precision, and a clean operating environment. Thanks to compressed air’s low density, these actuators typically deliver quicker response times than their hydraulic counterparts.

These devices are extensively utilized across various industrial applications, such as:

- Press machines

- Cutting tools

- Packaging equipment

- Oven door operations

- Mechatronics systems

- Others

The Bawalaksana Central Industrial team has developed an insightful article, 10+ Components of Pneumatic System You Need to Know. This comprehensive piece delves into the essential components of pneumatic systems, such as compressors, valves, actuators, and more, thoroughly explaining their roles and how they interact within the overall system.

By reading this article, you’ll gain valuable information about each component’s function, significance, and practical applications. It is a highly recommended resource for anyone looking to enhance their understanding of pneumatic technology. We encourage you to explore this article to understand the mechanisms driving efficient pneumatic operation.

Advantages of Hydraulic Systems Over Pneumatic Systems

Hydraulic systems present significant advantages over pneumatic systems, particularly when generating stronger forces and operating at higher pressures. This makes them particularly effective for pushing or lifting heavy loads. Typically, industrial hydraulic applications run at pressures between 1,000 and 5,000 Psi (69–344 BAR).

In more demanding scenarios, like mining or cranes hoisting heavy construction equipment, these pressure levels can soar up to 10,000 Psi.

On the other hand, pneumatic systems, often seen in industrial settings, manufacturing processes, or train braking systems, usually operate within a much lower pressure range of 72 to 145 Psi (5–10 BAR). This discrepancy arises because air has a lower density than oil and is easily compressed, making it less effective in exerting force than hydraulic fluids.

However, one key benefit of pneumatic systems is that they can achieve higher flow rates, allowing them to release energy quickly and respond faster. This quick response time enables pneumatic systems to complete cycles more efficiently, significantly boosting productivity.

In contrast, hydraulic systems, which depend on a thicker fluid, encounter more resistance to movement than the readily flowing air used in pneumatic systems. While they provide greater lifting force, hydraulic systems tend to be less responsive.

In summary, hydraulic systems are the go-to solution for lifting or moving heavy loads. In contrast, pneumatic systems shine in applications where speed, responsiveness, and high productivity are essential.

Advantages of Pneumatic Systems Over Hydraulic Systems

As Rowse highlights, pneumatic systems hold a distinct advantage over hydraulic systems in terms of cleanliness. The primary reason is that any leaks in pneumatic systems release air, which doesn’t pollute the environment or lead to significant adverse effects.

On the other hand, leaks in hydraulic systems can create serious issues; even with preventive measures, spilled hydraulic oil can contaminate soil, water, and surrounding ecosystems.

A notable benefit of pneumatic systems is their use of filtration units that effectively eliminate dirt, oil, water, dust particles, and other contaminants. This ensures that the air circulating through the system remains clean and dry.

As a result, pneumatic systems are often the preferred choice in industries that demand high cleanliness standards, such as electronics manufacturing, pharmaceutical labs, and the food and beverage sector.

Also, pneumatic systems appeal to companies that prioritize environmental responsibility and embrace sustainable manufacturing practices, often referred to as Green Manufacturing or the Green Deal.

One of the top manufacturers of pneumatic devices, Metal Work Pneumatic, has created cutting-edge equipment to enhance this concept. Leveraging advanced technical solutions, innovative technologies, and optimized device designs can significantly improve the efficiency of pneumatic systems.

Did you know that compressed air has become the fourth primary energy source, following gas, water, and electricity? In the industrial sector, it typically represents about 20% of a company’s total energy consumption.

Remarkably, this energy usage can be cut by one-third by utilizing appropriately sized products, configuring systems correctly, and analyzing compressed air consumption to implement necessary adjustments.

Choosing Between Hydraulic and Pneumatic Systems: A Guide

After exploring the key differences between hydraulic and pneumatic systems, it’s time to determine which one best fits your needs.

There are several factors to consider when making this choice, as outlined below:

Compatibility

The first step in selecting a pneumatic or hydraulic system is to assess its ability to meet the specific requirements of your application.

As mentioned, pneumatic systems are ideal for industries that prioritize high cleanliness and efficiency standards. In contrast, hydraulic systems excel in applications requiring substantial force to lift or maneuver heavy loads.

Take a close look at the weight of the load you need to lift, your resources, and any space limitations. A pneumatic system might be your best bet if the load is relatively light and cleanliness is a top priority in your working environment.

However, if you’re dealing with loads exceeding 70 kg and the environment isn’t particularly sensitive to cleanliness, opting for a hydraulic system could be the way to go.

Speed

In the Fast-Moving Consumer Goods (FMCG) sector, production speed is critical in achieving economies of scale and driving profitability. Most processes are carried out quickly, automatically, and continuously from start to finish.

Pneumatic systems are specifically designed to tackle this challenge. They are easy to maintain, simple to deploy, and perform well. As a result, a pneumatic system is an excellent choice when your industrial operations demand both speed and precision.

Using compressed air as the working medium, pneumatic systems offer rapid responses and can efficiently and accurately manage repetitive tasks. In today’s Industry 4.0 landscape, many pneumatic devices and components can operate automatically at impressive speeds.

By effectively harnessing the benefits of pneumatic technology, you can boost productivity and enhance your company’s profitability.

Cleanliness

Cleanliness is essential in the food and beverage, pharmaceutical, and medical industries, as well as sectors like electronics and semiconductor manufacturing, where a pristine environment is crucial for product quality and efficient operations. For these industries, pneumatic systems are the ideal option since pneumatic components help create a clean, contamination-free atmosphere.

In the food and beverage sector, many pneumatic products are already certified as food-grade and approved by the FDA, particularly those from reputable manufacturers like Metal Work and Mebra Plastik Italia. With access to top-quality pneumatic equipment, you can confidently develop an advanced automation system that prioritizes cleanliness and efficiency.

Conclusion

In conclusion, hydraulic systems demonstrate a substantial advantage in force and strength, making them ideal for lifting and transporting heavy loads. These systems transmit power using incompressible fluids, allowing for precise control over lifting mechanisms and enabling the handling of heavy machinery and materials in demanding applications.

On the other hand, pneumatic systems stand out in terms of speed, cleanliness, and energy efficiency. Compressed air systems are often faster and cleaner, making them suitable for environments where contamination must be minimized.

Both pneumatic and hydraulic systems are vital across various industries, including manufacturing, automotive, aerospace, and construction. They serve a multitude of applications, from assembly lines to machine operations. When integrated correctly into operational processes, both systems can significantly enhance productivity, safety, and operational efficiency.

Despite their respective strengths, each system also has inherent weaknesses. Hydraulic systems can be prone to leaks, leading to environmental concerns, while pneumatic systems might struggle under high-load conditions.

However, these drawbacks can often be mitigated through careful planning during the system design and implementation phases, ensuring optimized performance tailored to specific operational needs.

PT. Bawalaksana Central Industrial proudly serves as an authorized distributor of premier brands such as Metal Work Pneumatic, Mebra Plastik Italia, and Instruments To Industry (ITI). As a trusted supplier of an extensive range of industrial equipment, we are committed to being your reliable partner for maintenance, support, and repair services.

With over seven years of industry experience and a dedicated team of professional engineers, we are well-equipped to assist businesses in transitioning toward Industry 4.0.

We understand the need for continuous innovation and efficiency in today’s competitive market. Therefore, we invite you to consult our expert team to explore the most effective solutions tailored to your unique business challenges. Together, we can enhance your operational capabilities and achieve your goals.

Ready to take the next step?

Consult our experts today to discover customized automation and power transmission solutions that enhance productivity. Click the consultation button below to connect with our expert team and discuss your unique needs.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)