Pneumatic systems have become indispensable to various industries due to their efficiency and cost-effectiveness. These systems rely on several crucial factors, such as air quality, pressure, and flow rate, to ensure smooth operation.

Ignoring these factors can lead to system failure, resulting in significant losses in costly repairs and downtime.

In automation systems, pneumatic systems are crucial in achieving effective and accurate equipment operation. However, to achieve optimal performance, it is essential to consider three critical factors:

- The most vital components.

- The implementation of best practices.

- Solutions to technical issues that may arise.

In this article, we will examine these factors in depth, providing valuable insights into how they impact the performance of pneumatic systems.

We will also offer practical solutions to technical problems that may arise, enabling you to plan, construct, and maintain pneumatic systems with precision and efficiency.

By familiarizing yourself with these critical factors, you can ensure that your pneumatic systems operate efficiently and achieve optimal performance.

Vital Components in the Proper Functioning of a Pneumatic System

It is essential to adhere to specific guidelines to achieve optimal functionality of the pneumatic system. These guidelines are as follows:

- Supply of high-quality, clean, and dry air

- Properly installed pneumatic pipe or hose network

- Implementation of all components according to industry standards

- Correct air pressure adjustment according to system requirements

- Lubrication of moving components

- Utilization of an electric controller for operation and automation

- Regular maintenance to prevent damage and leakage

- Use of safety equipment to reduce the risk of accidents

- Adequate knowledge and training

In the next section, we will explain all the abovementioned points, grouping them into three crucial factors for the pneumatic system to work correctly.

First Factor: Paying Attention to Essential Components in Pneumatic Systems

Building efficient pneumatic systems, including essential components, is crucial to ensure their smooth functioning. Some of these components comprise the following:

- Air Compressor

- Refrigerated Air Dryer

- Air Reservoir Tank

- Air Service Unit

- Regulator

- Pneumatic Valve

- Pneumatic Tubes

- Fittings

- Solenoid Valve

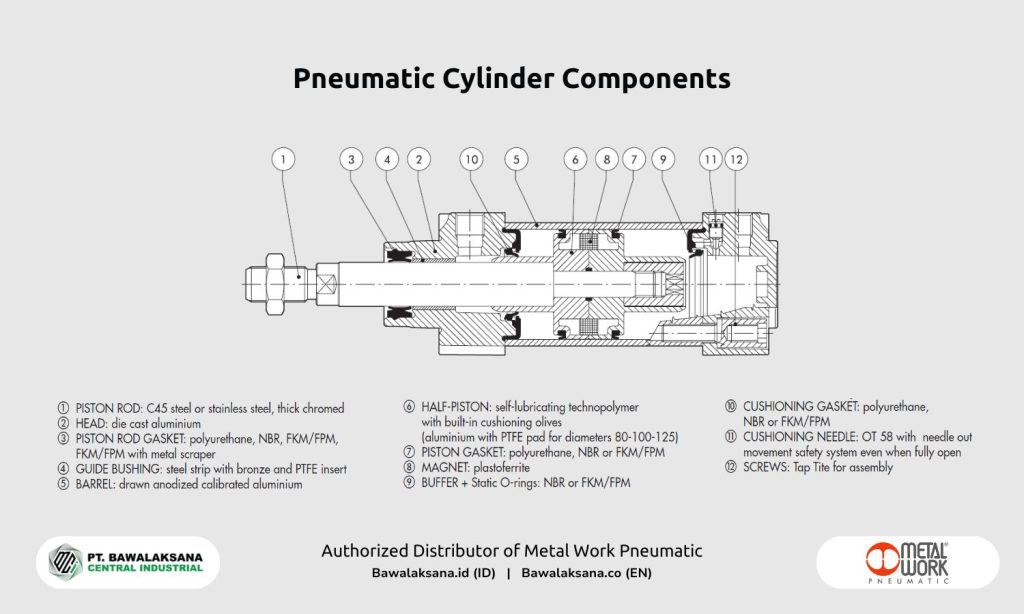

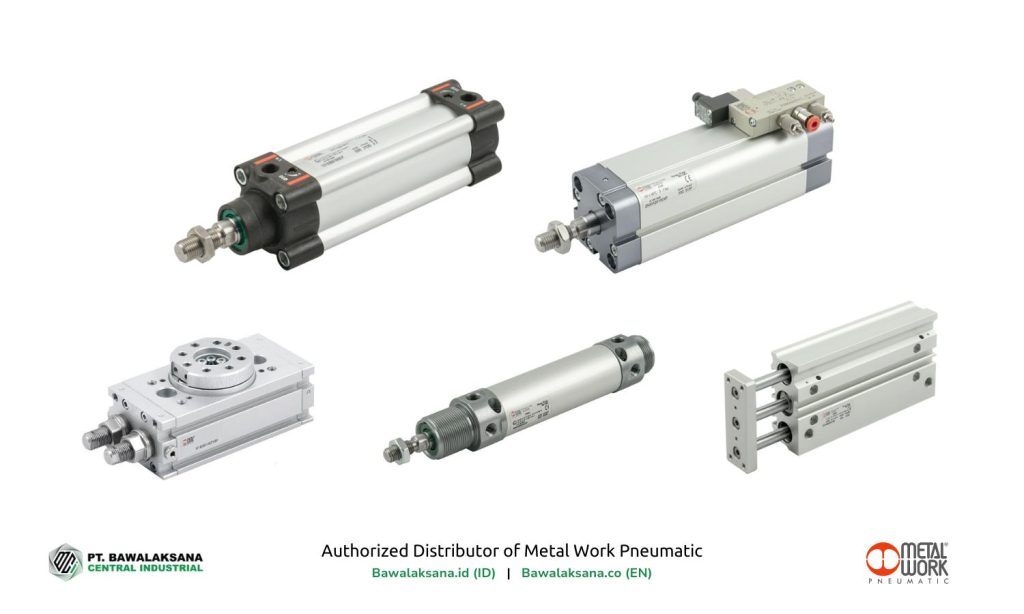

- Pneumatic Cylinder

- Others

It is imperative to have a comprehensive understanding of the components of a pneumatic system, as each component plays a vital role in determining the overall quality of system performance.

A previous article, 10+ Components of Pneumatic System You Need to Know, comprehensively explains each component’s functions and benefits.

It is essential to ensure that the pneumatic system comprises all the necessary components to ensure optimal performance, safety, and longevity of the devices. Therefore, selecting the appropriate components for your pneumatic system is recommended to guarantee its smooth and reliable operation.

Second Factor: Implementation of Pneumatic System According to Best Practice

Pneumatic systems are widely used in the industry for automation systems due to their popularity as a cost-effective choice for systems that require mechanical motion.

These systems can perform component transfer, positioning or clamping, and other essential functions. However, if they are not correctly designed or implemented, they may encounter issues and problems.

Therefore, it is highly recommended for your company to be aware of the possible incidents that can occur to operate the system effectively:

- Setting the air pressure that is too low or variable

- Improper use of air flow controllers

- Ignoring the decrease in cylinder performance when activating the system.

- Allowing pneumatic cylinders not properly to exhaust air

- Ignoring inconsistent or too-slow pneumatic cylinder speed

- Not paying attention to cylinder movement that is too harsh or not smooth

- The Solenoid Valve is locked, stuck, or even leaking

As an additional resource, we’ve developed a comprehensive guide on optimizing the efficiency and performance of pneumatic systems. Explore our page: How to Improve Pneumatic System Efficiency for Green Manufacturing.

Why Should You Engage an Experienced Expert Team?

Partnering with an experienced expert team ensures you can anticipate challenges and implement the right solutions proactively.

This approach helps your company avoid unexpected downtime or system failures caused by unforeseen circumstances.

As an official Industrial Automation equipment supplier, we offer more than quality products. Our professional team, with years of expertise—particularly in Pneumatic System Automation—is ready to assist you in overcoming even the most complex system challenges.

Our experts can provide tailored, professional support to restore efficiency and reliability if your pneumatic system has unresolved issues.

Engaging an expert team isn’t just about ensuring proper equipment operation. It’s about delivering strategic, practical solutions that drive productivity and sustained growth for your business.

Third Factor: Understanding Common Problems in Pneumatic Systems and Their Solutions

Pneumatic systems offer numerous advantages that can significantly enhance a company’s productivity. However, it’s essential to acknowledge that these systems can encounter specific issues that, if neglected, may disrupt their performance and efficiency.

Fortunately, the problems associated with pneumatic systems are generally simple, especially when anticipated and addressed by a competent engineering team.

In this section, we will delve into some common problems frequently encountered in pneumatic systems, including:

Inconsistent Air Pressure

Inconsistent air pressure is one of the most significant challenges pneumatic systems face. It can lead to unpredictable and irregular movements of pneumatic cylinders, affecting the system’s overall performance. Therefore, it is crucial to design the system correctly and equip it with suitable air flow controls to mitigate this issue.

One of the significant problems caused by inconsistent air pressure is challenging speed control. When air pressure varies, it can affect the speed of the pneumatic cylinder, making it difficult to control and regulate. This can result in a decrease in productivity and efficiency levels.

Additionally, inconsistent air pressure can compromise precision levels, which can be a critical concern in applications requiring high accuracy levels. Even slight variations in air pressure can affect the system’s accuracy, leading to errors and inconsistencies.

To proactively address these concerns, it is advisable to utilize high-quality devices obtained from authorized distributors or reputable industrial equipment suppliers. These devices are designed to withstand varying air pressure levels and maintain consistent performance, ensuring optimal system performance and longevity.

Cylinder Speed Issues

Various factors can cause cylinder speed issues in a pneumatic system. These factors may include low air pressure, using oversized cylinders, damaged or undersized pneumatic hoses, or malfunctioning solenoid valves. To resolve these issues, it is essential to adjust the components accordingly. Here are some recommended measures to address these cylinder speed issues:

Check Air Pressure

Make sure that the air pressure entering the pneumatic system is sufficient. Low pressure can cause the cylinder to move slowly. Consider using a pressure regulator to adjust the air pressure according to the recommended specifications.

Evaluate Cylinder Size

If the cylinder size is too large for the application, it can result in inefficient speed. This typically occurs when the compressor capacity is insufficient. It is advisable to use a cylinder with the appropriate diameter that matches the load to be moved to enhance speed.

Cleaning and Maintenance

Remember that dust or dirt in the pneumatic system can slow down cylinder operation. Therefore, regular maintenance and cleaning or replacing worn-out components are essential.

By paying attention to these factors, you can improve the speed of your cylinders and enhance the overall efficiency of the components in your pneumatic system.

Leakage and Noise

Leakage and noise in pneumatic systems can be significant issues, leading to higher operational expenses. However, a properly designed and well-maintained pneumatic system typically operates smoothly and quietly.

What Causes Noise in Pneumatic Systems?

Noise can occur in pneumatic cylinders if the bearings at the base of the pneumatic cylinder are not sufficiently adequate when the stroke reaches the stop point.

Regularly replacing the cylinder bearings in your machinery can significantly reduce the noise levels and prevent excessive wear and tear. This proactive step ensures the longevity of your machinery and increases its efficiency, leading to better performance and output.

Tips for Dealing with Leaks

Leakage in pneumatic systems can be caused by various factors, including:

- Worn-out valves

- Cracked or broken pneumatic hoses

- Poorly installed fittings

- Damaged connectors

- And others

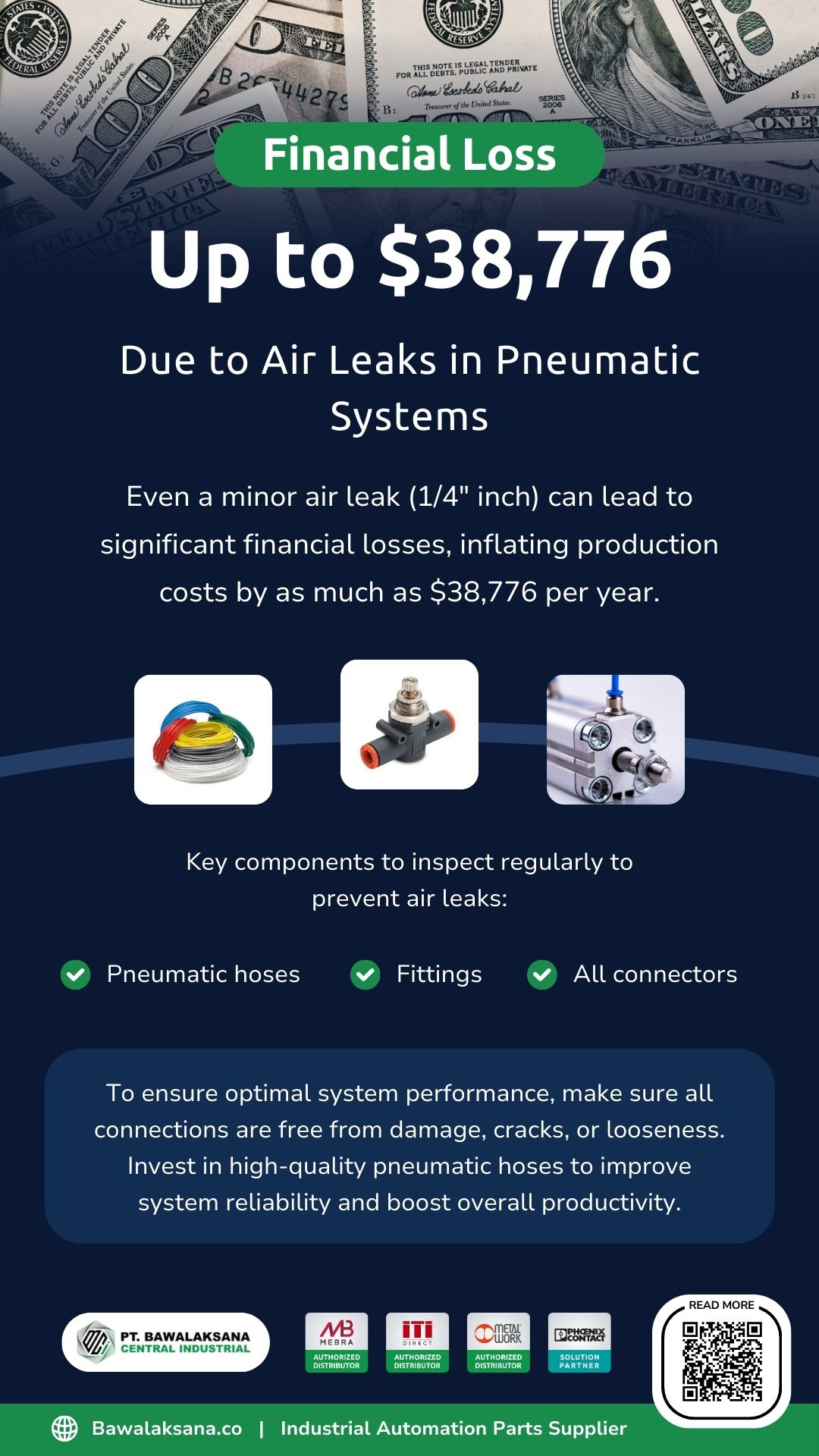

It is important to note that detecting leaks in pneumatic systems can be challenging. Unnoticed pressure drops can decrease system performance.

Pneumatic system leaks can lead to a significant increase in production costs, up to $38,776

According to the US Department of Energy, even a small leak of just 1/4″ (6.35 mm) in a pressurized air line can have significant financial implications, potentially increasing production costs by up to $38,776 per year, calculated through cost savings formulas. It’s crucial to recognize that unaddressed leaks in the pressurized air system can result in the wastage of 20%-30% of the output generated by the air compressor.

These issues can precipitate a range of other problems, including:

- Fluctuations in pressure within the system can cause components to operate inefficiently and consequently impact production quantities.

- Increased demand for compressor capacity leads to higher costs than necessary.

- Reduced lifespan and heightened maintenance costs, including those associated with compressor packages.

What do we do when a leak occurs in the pneumatic system?

The most effective method for identifying leaks is an Ultrasonic Acoustic Detector, renowned for detecting high-frequency hissing sounds commonly associated with air leaks. This device allows for precise pinpointing of leak locations, facilitating efficient and timely repairs.

To maintain optimal performance and prevent potential issues, it is advisable to take the following precautions, even in the absence of a pneumatic system leak:

- Conduct routine inspections to ensure all components are functioning correctly and leak-free.

- Pay particular attention to pneumatic hoses, fittings, and connectors, checking for signs of damage, wear, or looseness.

- Thoroughly investigate any suspicious sounds that may indicate leaks originating from components. Then, inspect all valves to ensure correct installation.

- Upon identifying the source of a leak, promptly perform repairs or replace damaged components to prevent further complications.

Water Accumulation in Air Lines

Moisture in the air is a significant challenge for pneumatic systems. Water vapor can condense during compression and temperature fluctuations, leading to water accumulation in air lines and components, such as valves and cylinders, which are particularly vulnerable to corrosion.

In pressurized air systems, water flows along with the air. With enough pressure, this water can act like a “cleanser,” stripping away essential lubrication from solenoid valves, cylinders, and other components.

Without proper lubrication, these components are at higher risk of corrosion, wear, and severe damage. Over time, water accumulation can cause extensive harm, including cracked pneumatic hoses, rusted cylinders, jammed valves, and more.

To mitigate water accumulation in pneumatic systems, consider the following best practices:

- Install drain valves and water separators to manage moisture effectively.

- Remove water regularly from critical points prone to accumulation, such as air storage tanks, FRL units, and drain valves.

- Use refrigerated or desiccant air dryers, especially in highly humid environments.

For a more in-depth guide, see our article How to Properly Drain Air from Pneumatic Systems and Understand Its Importance.

Why Is Implementing Pneumatic Systems in Industry Highly Beneficial?

Pneumatic systems are favored across industries due to their reliability and versatility despite their limitations. When implemented professionally and tailored to specific applications, these systems can deliver significant advantages for your business.

Key benefits of pneumatic systems include:

- Exceptional Durability: Components are designed to withstand rigorous use.

- Speed and Reliability: Ideal for repetitive tasks requiring consistent performance.

- Cost-Effectiveness: High accuracy with minimal operational costs.

- Ease of Use: Simple design, straightforward installation, and low maintenance requirements.

Pneumatic systems are particularly well-suited for challenging environments, operating reliably in high temperatures and dusty settings.

With proper care and maintenance, these systems can overcome numerous industrial challenges, even in extreme environments, making them a robust solution for many applications.

Industries That Benefit from Pneumatic Systems

Pneumatic technology has a wide range of applications, including:

- Manufacturing

- Construction

- Aerospace

- Medical

- Textiles

- Railway

- Oil and Gas

- Printing Machinery

- Pulp and Paper

- Car Wash Systems

- Industrial Robotics

- Automotive

- Plastics and Packaging

- Industrial Automation Systems

- Chemical Processing

- Food and Beverage

For a detailed exploration of these applications, check out our article: 15+ Industries Utilizing Pneumatic Systems.

Essential Considerations for Pneumatic System Design

Designing an effective pneumatic system involves careful planning, considering critical aspects like location and infrastructure, and selecting the right components for the job.

However, to maximize Pneumatic System Automation, it’s crucial to address common challenges proactively and follow best practices in system implementation.

By focusing on the three key factors we’ve outlined, you can ensure your compressed air system operates at peak efficiency.

Moreover, leveraging these modern systems optimizes performance and unlocks significant benefits for your business, driving productivity and long-term success.

PT Bawalaksana Central Industrial is an Authorized Distributor of Metal Work Pneumatic and Mebra Plastik Italia. We offer comprehensive solutions for designing pneumatic system automation tailored to your industry’s specific needs.

Since 2017, we have been a trusted supplier of Industrial Automation equipment. We bring years of expertise recommending the best pneumatic system components to optimize your operations.

Our professional engineers are ready to help you plan and design an efficient and effective pneumatic system, enabling your business to achieve enhanced cost efficiency and productivity.

Contact our expert engineering team today for accurate and tailored recommendations to support your success.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)