Industrial and production automation systems are proven to increase operational productivity by up to 50% as measured by WIP movement per operator per day.

This is as mentioned in the case study released by Systema titled, “A Guide to Digital Transformation in Manufacturing”.

WIP (Work in Progress) in this case includes all raw materials, labor, and overhead costs that have been incurred for products being produced in manufacturing.

PT. Bawalaksana Central Industrial as Authorized System Integrator and Solution Partner for Phoenix Contact can be the best partner for your company in implementing industrial automation systems and production systems and digital transformation for manufacturing.

We have access to the entire Phoenix Contact product portfolio, and can provide comprehensive support on Electrification, Networking and Automation.

Headquartered in Blomberg, Germany, Phoenix Contact develops cutting-edge solutions that adhere to the highest industry standards and drives the technological advancement of the industry by bringing the concept of Digital Factory.

At the same time, we also provide complete solutions for your industry by becoming an Authorized Distributor for Metal Work Pneumatic and Italian Plastic Mebra.

This partnership is proof that Bawalasana.id is a reliable partner in providing comprehensive solutions to build industrial-scale pneumatic automation systems that can be connected digitally.

Key Technologies in Industrial Automation and Production Systems

We provide a wide range of technologies and hardware for industrial automation and production systems in industry as well as a key foundation in building smart manufacturing that is future-ready operations.

Through our solid partnerships in Europe and Asia, we can provide complete solutions for sustainable Digital Factory implementation.

It should be recognized that in building a sustainable industrial automation system, various components and technologies are needed that are interrelated and cannot be ruled out.

In this article, we would like to provide some important insights into key technologies in intelligent and adaptive automation of production systems, as follows:

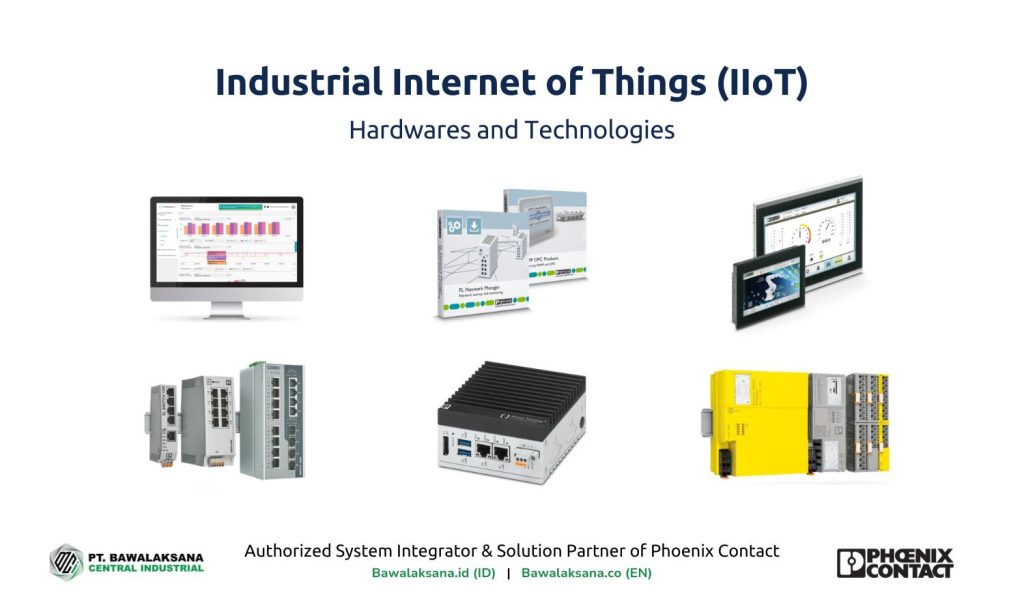

Industrial Internet of Things (IIoT)

The Industrial Internet of Things or IIoT for short is a major revolution in manufacturing that can connect physical devices to the digital ecosystem.

Production systems supported by IIoT are able to automate many processes that previously required manual intervention. This technology can significantly reduce production cycle time and minimize human error.

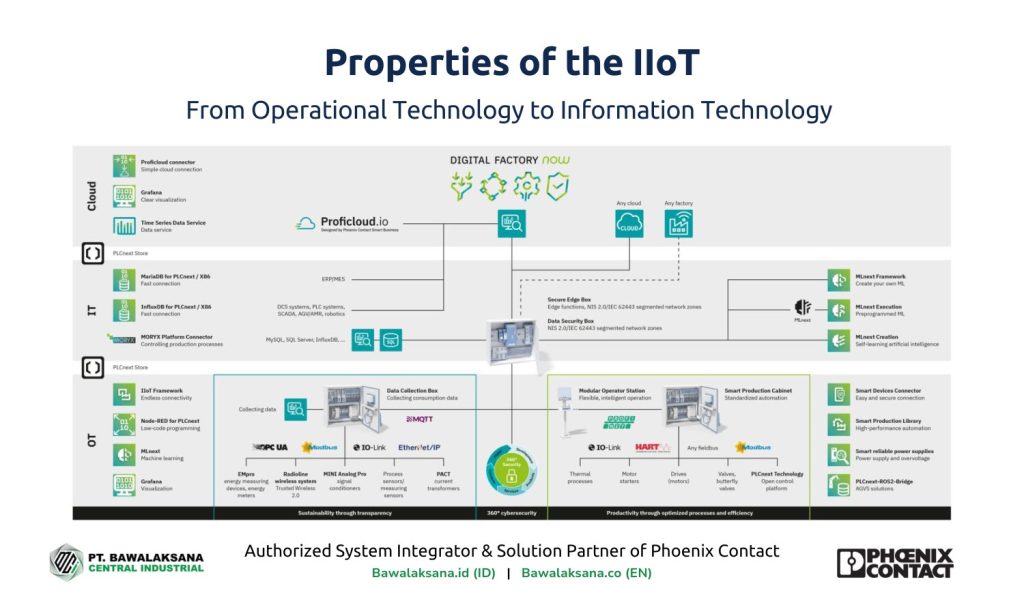

We have an IIoT Framework that can integrate Operational Technology (OT) and Information Technology (IT) in a practical and scalable way.

IIoT Framework is a bridging that can seamlessly connect brownfield and greenfield environments (infrastructure under construction/migration) without forcing them to make drastic changes.

Regardless of what phase your company is currently in, digitally connected industrial automation can be realized easily with this framework. Either do it gradually or in totality, according to the needs in your industry.

Among the most basic devices and technologies in IIoT are as follows:

- IIoT Platform: Smart Services designed for industry, including standardized and scalable cloud services. This platform will help your company in operational and maintenance processes with a high level of efficiency.

- Automation Software: This is software specifically designed to run industrial automation seamlessly and effectively. Automation software plays an important role in carrying out human-system interactions with innovative and intuitive functions.

- Edge Computing: Equipped with PLCnext Technology, next-generation Edge Computing combines the robustness of an industrial PC with an open and scalable ecosystem. It can process large amounts of data so that applications can respond faster and more flexibly.

- HMI & Industrial PC: Human Machine Interface (HMI) makes it easy to control machines, while industrial PCs are sophisticated hardware designed to run fast and safe computing processes to control machines.

- Industrial Communication System: Industrial automation in a wide scope will not be able to run unless there is reliable data transmission, starting from the control level to the factory floor. These devices also need to be supported by network security systems through various industry standard protocols to increase System Availability and minimize vulnerability.

- PLC & I/O: Intelligent control systems (PLCs) and reliable I/O stations are critical to industrial automation and the Digital Factory ecosystem. Future smart manufacturing relies heavily on IEC 61131-3 international standard PLC platforms, and can adapt to AI technologies and sustainable energy projects.

Bawalaksana.id as a trusted partner for Industrial Automation Solution and System Integration can provide you with a comprehensive solution for all the things we have mentioned above.

Using Phoenix Contact’s reliable and advanced innovations, we can help you to implement the Industrial Internet of Things (IIoT) in your company seamlessly and practically.

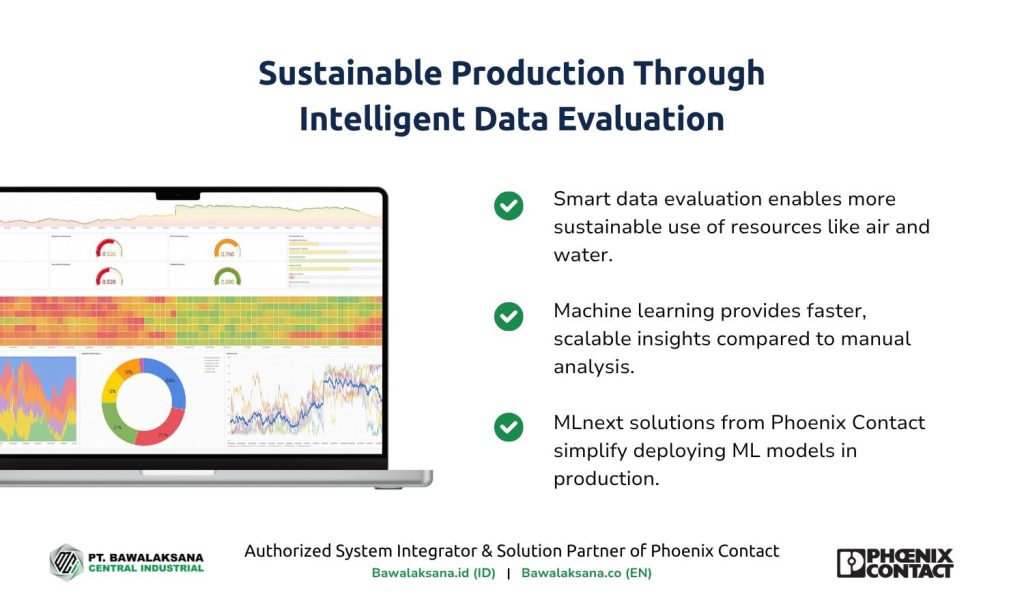

Integration of AI and Machine Learning for Quality Control

The integration of AI and Machine Learning in industrial automation is numerous, including:

- Anomaly detection and production optimization

- Predictive maintenance

- Improved product quality and consistency

- Energy efficiency and waste reduction

- Data-driven decision making

For your information, when AI was first invented in the industry (around the 1960s), it was considered too advanced for its time.

However, when it reached the decade of the 2010s, AI came back into the spotlight after rapid advances in the hardware sector, the emergence of the Internet of Things (IoT), and the widespread implementation of Cloud Computing and Edge Computing.

Using PLCnext Technology’s platform, manufacturers can integrate AI and Machine Learning integration, and run it through the edge and cloud.

PLCnext Technology is a platform with a flexible programming ecosystem. You can develop applications in various languages, such as C, C++, Python, Ladder Logic, Function Block, Matlab or Structured Text, and then integrate them seamlessly through the Global Data Space (GDS).

Moreover, PLCnext Technology has opened up a powerful new architecture to increase industrial productivity.

For example, one task may retrieve data from sensors in parallel, while another task simultaneously runs AI inference using that data directly at the edge.

Data can also be sent to the cloud via protocols such as MQTT and complex AI models run remotely, and the results accessed back by the PLC.

PLCnext’s advanced technology makes it easy to execute AI in advanced industrial cases, such as Machine Learning (ML)-based anomaly detection.

Thus, PLCnext Technology has an important contribution to make in the effort to achieve the Net Zero Emission target that will be targeted to be realized in 2050.

Cloud Computing for Industrial Scalability and Production Efficiency

Running Cloud Computing for complex industrial sectors is a complicated and challenging task. Especially if not managed properly using the right platform.

Meanwhile, in today’s smart industrial era, Cloud Computing has become vital to implement.

Cloud Computing plays an important role in performing cloud computing, data storage and applications in a flexible and scalable manner without the need for large infrastructure investments.

By utilizing this technology, your company can save operational costs by adjusting production capacity according to rapidly changing market demand.

However, please note that Cloud Computing services have several challenges in their implementation, such as:

- Cloud misconfiguration

- Insecure API

- Strict regulations

- Cyber security

Therefore, we are here to make it easier for you to face this challenge. By providing a wide selection of technologies and professional services in accordance with international standards.

The following are some important technologies to ensure your company’s Cloud Computing infrastructure is at the most optimal level:

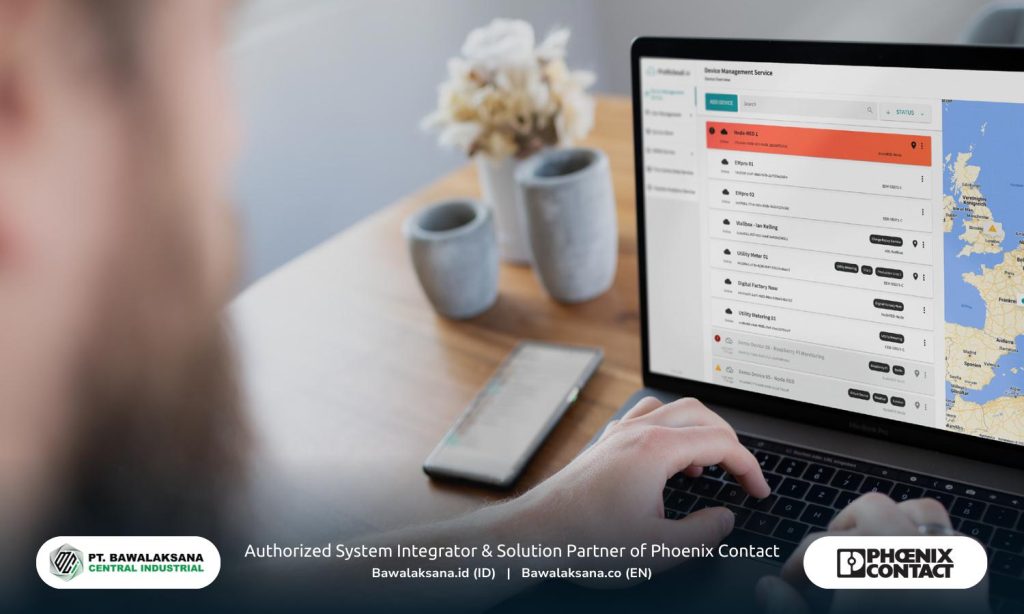

- Proficloud Smart Services: A comprehensive Industrial Smart Services for cloud services and data analytics in industrial automation. It offers a wide range of industry-leading features that are easy to use, and provide realtime transparency, predictive analytics, process optimization and data-driven decisions. Proficloud is a key enabler of digital transformation for small enterprises to large manufacturers.

- mGuard Secure Cloud: A turnkey cloud service for remote maintenance of high-security machines with VPN-encrypted communication. mGuard Secure Cloud enables secure remote access to machines and production systems anywhere and anytime, from around the world. This contributes significantly to reducing the cost and time of field visits.

- Cloud Clients: These are hardware devices that can connect machines to the mGuard Secure Cloud with high security protection. This technology supports scalable remote maintenance.

- PLCnext Technology: Smart PLC technology with an open ecosystem, supporting Edge Computing and Cloud Computing. PLCnext has the advantage of running AI-based applications and connecting with various cloud services for real-time production monitoring and control.

By using reliable and comprehensive Cloud Computing technology and services as we mentioned above, the productivity of the automation system in your company can run optimally and sustainably.

With Bawalaksana.id, you can realize the implementation of Digital Factory from sensor level to cloud level. We can provide all the technology you need to connect production machines to the digital world and realize sustainable smart manufacturing.

Industrial Automation to Scale Up Production

There are many industrial automation system devices that have been available to date. From pneumatic systems to collaborative robots, we can provide support for your industry from planning, implementation to maintenance.

Through our partnership with Metal Work Pneumatic, we can implement pneumatic automation systems for various industrial sectors, such as F&B, petrochemical, pharmaceutical, electronic manufacturing, automotive and others.

We can integrate Metal Work’s EB80 Electro-Pneumatic system with Phoenix Contact’s PLCnext Technology to achieve high productivity and energy efficiency.

For your information, pneumatic systems are the most popular and economical technology for industrial automation applications that require mechanical movement.

This is because pneumatic systems have many advantages and can answer various industrial challenges in the critical sector, such as:

- Operational security

- Flexibility to technology

- Low initial investment cost

- Ease of maintenance

- High component durability

By implementing reliable and highly durable industrial automation technology, your company can achieve a linear increase in production scale and business profits.

If your company has plans to implement industrial robots on a more complex scale, please talk to our Application Engineer team to get more detailed information.

Digital Factory Now: Start Implementing a Smart Industrial Automation System for the Future

PT. Bawalaksana Central Industrial is your best partner for the implementation of industrial automation systems and manufacturing digitalization to increase productivity, energy efficiency and business profits.

With more than 7 years of experience and strong partnerships across Asia and Europe, we can provide complete support.

Through proper planning, reliable technology and a professional team, we can help you realize a smart industry for the future.

Connect with our team of Application Engineers to discuss the best plan to build the ultimate foundation for quality industrial automation.

Please click the Contact Us button below and let’s get started on a sustainable Digital Factory implementation.

Piko Prasetyo

Application Engineer

This article was written in collaboration with Piko Prasetyo, an expert in Automation, Embedded Systems and Artificial Intelligence, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)

![Problems with 3 Phase Contactors and How to Solve Them [Practical & Effective]](https://bawalaksana.co/wp-content/uploads/2025/07/Masalah-Pada-Kontaktor-Motor-3-Phase-dan-Cara-Mengatasinya-Bawalaksana-ID-1080x675.jpg)