Industrial power supplies are important components that contribute to providing a stable supply of voltage and current to various equipment, machines and control systems in smart manufacturing.

By providing a stable power supply and a high level of availability, expensive equipment in manufacturing can operate without interruption, avoiding damage and unplanned downtime.

Power Supply is a key technology to ensure system availability in various industrial sectors and digital infrastructure, such as:

- Industrial automation and control system

- Telecommunication infrastructure, data centers, and servers

- Medical equipment and imaging

- Electric vehicle charging station

- Electric railway infrastructure

- Renewable energy system

- Building automation

- Process industry

- Others

In this article related to Industrial Power Supply, the Bawalaksana.id team would like to discuss some interesting things as follows:

- Definition and basic functions of industrial Power Supply

- Difference between industrial and conventional Power Supply

- Benefits of industrial Power Supply benefits in various vital sectors

- The Critical Role of Industrial Power Supply for Digital Factory Sustainability

What is an Industrial Power Supply?

Industrial Power Supply is an important part of the industrial electrical system that serves to provide a continuous supply of voltage and electric current to various electronic systems. Thus the system availability is at the most optimal level.

In addition to serving to provide electricity supply, industrial Power Supply also serves to protect electronic equipment from voltage spikes or electrical disturbances that could potentially cause damage and downtime.

In fact, industrial power supplies equipped with advanced technology make an important contribution to keeping factories away from potential hazards to protect people, machinery and the environment from fatal system failures (e.g. fire or explosion).

Therefore, industrial power supply has an important contribution to ensure every machine, control system and electronic equipment in the industry can operate properly and sustainably. As well as ensuring the sustainability of a safe and comfortable environment (Environmental Sustainability).

Also keep in mind, that the most basic function of the Power Supply is to regulate the incoming power source from the outlet (AC current), then convert it into power with specifications that match the needs of industrial equipment (usually DC current).

However, the features and specifications contained in industrial Power Supplies are more complex and have higher standards than conventional types.

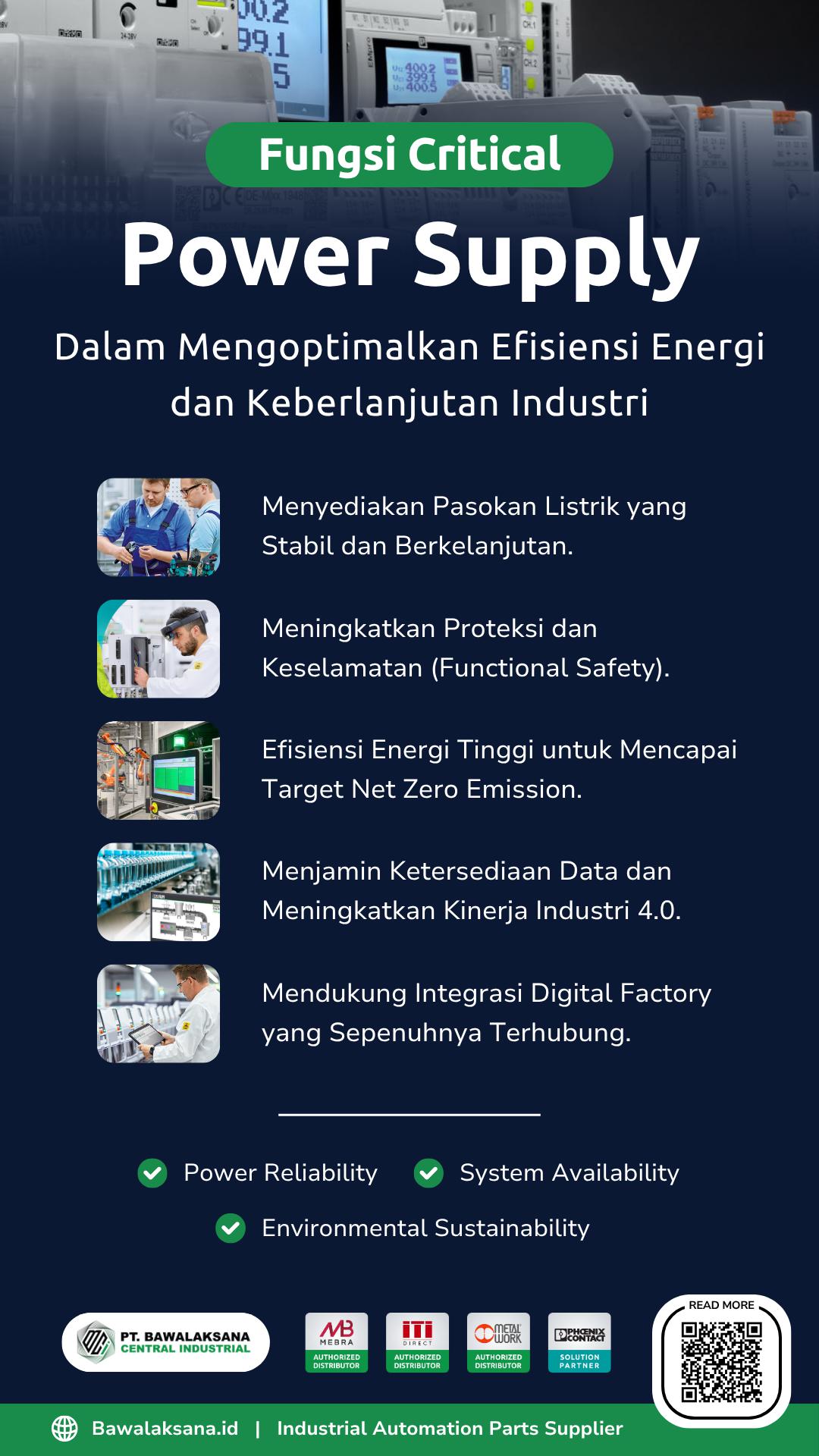

The following is a brief overview of the functions and benefits of Power Supply in optimizing Energy efficiency and industrial sustainability in the Industry 4.0 era:

- Providing Stable and Sustainable Electricity Supply: Supplying voltage according to the specifications of industrial equipment, including providing strong power for large starting loads, thus supporting the smooth operation of industrial machinery.

- Improving Protection and Safety (Functional Safety): Maintain the safety of people, machines and the work environment with safety functions according to the Safety Integrity Level (SIL 3) standard.

- High Energy Efficiency to Achieve Net Zero Emission Target: High-efficiency power supplies (over 95%) help in reducing energy consumption and carbon footprint, while cutting plant operating costs.

- Ensure Data Availability and Improve Industry 4.0 Performance: Reliable power availability is an important key to achieving optimal performance for all IoT systems and devices in Industry 4.0.

- Supporting Fully Connected Digital Factory Integration: Industrial power supplies are the “bridge” that connects the physical infrastructure (electrical equipment and machinery) across the Digital Factory network.

To better understand the differences in function, benefits and advantages between industrial and conventional Power Supply, here we provide a complete explanation.

Functions, Benefits and Advantages of Industrial Power Supply Compared to Conventional Type

There are many things that distinguish between industrial and conventional Power Supply, apart from the amount of wattage released, components, features and technology.

Although both have the same fundamental function, which is to provide voltage and current supply, Industrial Power Supply actually has more complex functions and benefits.

In this section we will explain some of the functions, benefits and technologies found in Industrial Power Supplies that are not found in conventional types.

We reviewed it from three aspects, namely:

- Stability

- Reliability

- Durability

The following is an explanation of the functions, benefits and advantages of industrial Power Supply:

Component Stability in the Face of Extreme Environments

Power Supply component stability is the first aspect that needs to be considered to ensure System Availability in the manufacturing sector. Through good component stability, the Power Supply can deliver consistent and stable power to various important devices in manufacturing.

Power supply components that are unstable (prone to interruptions) are prone to problems when faced with extreme industrial environments. This weakness can have a direct negative impact on production floor operations and business sustainability.

Meanwhile, environmental challenges in industry are diverse and complex, such as:

- High or low temperature

- Humidity

- Interference

- Vibration

- Dust

The good news is that industrial-grade power supplies have a very good level of component stability and exceed the standards of conventional type power supplies. In fact, industrial Power Supply is deliberately designed to face a variety of very extreme environmental conditions.

One type of industrial Power Supply that is very reliable is the 3rd generation TRIO POWER from Phoenix Contact with the following advantages:

- It can be safely used for extreme industrial environments in the oil and gas, pharmaceutical, automotive and other sectors.

- Has a protective coating for protection against exposure to corrosive gases, dust and environments with 100% humidity.

- Can be used in an ambient temperature range of -40°C to +70°C.

- It has passed ATEX and IECEx tests making it safe for use in sectors prone to sparks and fires.

For information, the stability of the Power Supply needs to be supported by comprehensive protection, advanced technology and good component quality. Thus, the device is safe for use in applications that have severe environmental challenges such as the petrochemical, automotive, oil and gas industries.

Meanwhile, conventional types of Power Supply are not designed to face challenges such as those found in the industrial sector. Therefore, this first aspect becomes an important point that distinguishes between industrial and conventional Power Supply.

Best Reliability for Availability System in Manufacturing

Power supply reliability is a crucial aspect that needs to be considered because it contributes importantly in maintaining the stability of electricity supply to various industrial machines and equipment.

As is well known, that voltage disturbances in industry often occur due to several things, including:

- Sudden load changes

- Lightning strike

- Short circuit

- Overload

Did you know?

Voltage disturbances have the potential to cause damage to various machinery and equipment, which can lead to large losses.

Industrial Power Supply with Selective Fuse Breaking (SFB) Technology can be the best solution to anticipate this threat.

SFB technology serves to prevent electrical disturbances from escalating into bigger and more serious problems, such as damage to industrial equipment or production downtime.

SFB Technology has a function like a Miniature Circuit Breaker (MCB) that can selectively disconnect certain circuits / lines for Fault Isolation from electrical problems.

This feature is important to prevent a total system shutdown due to an electrical fault arising from one of the components or due to voltage changes in the industry. This function helps to keep production uptime at its most optimal level.

Imagine what would happen if SFB Technology was not available in industrial power supplies for critical applications. Power problems in one part of the production plant could have implications for overall downtime and huge financial losses.

Industry Case Examples:

On high-speed production lines, you can find various components of complex industrial automation systems, ranging from SCADA, PLC, industrial IoT, wireless communication systems, motors, actuators, sensors and other control systems.

All such equipment requires a superior supply of electrical power to perform complex functions and realtime process control.

If the electrical system is not equipped with selective disconnection or MCB for fault isolation, then every time there is an electrical problem in the system, it will potentially cause unplanned downtime.

This will lead to various problems on the production line, such as:

- Production operations stopped completely

- Production raw materials are wasted due to production batches that cannot be completed

- Financial loss due to unplanned downtime and production failure

- Unable to achieve production targets according to deadlines

Therefore, SFB Technology is vital to maintain the best reliability of system availability in manufacturing.

One Power Supply with SFB Technology is QUINT POWER from Phoenix Contact that can provide up to 1000 Watts of power, as well as with the following advantages:

- SFB Technology to prevent system failure due to voltage disturbances.

- Static Boost up to 125% continuously to facilitate system expansion without the need to replace the Power Supply (saving investment costs).

- Dynamic Boost up to 200% for 5 seconds to assist the starting of heavy loads such as electric motors or appliances that require a short burst of current.

- Preventive Function Monitoring for early warning in case of critical operating conditions, so as to prevent failures from actually occurring. This feature is essential to prevent unplanned downtime and is an important part of the safety features.

- Equipped with a comprehensive component protection system to deal with surge protection, vibration, extreme heat and harsh industrial environment conditions. The power supply device becomes more durable and less prone to damage.

- High efficiency of up to 95% and long service life, making an important contribution to the Digital Factory ecosystem and the realization of the Net Zero Emission target.

In conclusion, industrial power supplies are excellent for industrial applications that demand reliability in various aspects, including protection against extreme environmental challenges and protection against voltage spikes. Such advantages are certainly not found in conventional types of Power Supply.

High Durability for Long Usage Life

The high durability of power supplies has an important contribution to avoiding financial losses due to system failure or environmental factors.

Using high-tech devices is the best investment to get a positive return on investment (ROI).

As we have mentioned in the previous point, that industrial Power Supply plays a vital role to prevent potential damage to industrial equipment and unplanned downtime.

Durability is the next point that has a major impact on industrial productivity and business sustainability.

This is not without reason, as challenges in the most vital industrial environments are difficult to predict. Even a very small error can have multiple negative implications if there is no proper risk mitigation.

Therefore, as an industry that operates in critical sectors, using a Power Supply that is proven to have high durability is no longer an option, but it is a necessity.

Speaking of Power Supply applications in critical sectors (Demanding Application), you will be dealing with a variety of very complex safety regulations, such as:

- Safety Integrity Level (SIL) where devices must be equipped with safety functions, especially in applications in the power generation, chemical, oil & gas and industrial process sectors that endanger human life if they fail.

- ATEX and IECEx standards for applications in hazardous zone, explosion-prone environments due to accumulation of static electricity, such as oil and gas processing industries, chemical and other industrial processes.

In addition to having to meet high industry standards for Demanding Application, industrial Power Supply is also required to have advanced technology and components that are not easily damaged.

This is important because each component will complement each other and ensure long-term safe operation. When a component is damaged, at least the safety function is still functioning properly.

QUINT POWER Plus is one of the best Power Supply to answer this kind of challenge. Because it is proven to have high durability for various applications in the most vital sectors and has several advantages such as the following:

- MOSFET Integrated Decoupling for 1+1 and n+1 redundancy and resulting in symmetrical and balanced load distribution.

- Functional Safety (SIL 3, HFT=1) in accordance with international standards IEC 61508 and IEC 61511, guarantees a high level of safety (failsafe feature) especially for the most vital industrial applications to protect people, machines and the environment.

- It complies with ATEX and IECEx Standards for Hazardous Zone (Zone 2), and is equipped with protective coating and certification according to IEC 60079-0, IEC 60079-7, IEC 60079-11, and IEC 60079-15 standards. By meeting these standards, QUINT POWER power supplies can be used in potentially explosive areas, such as chemical, oil and gas, pharmaceutical, and other industries.

- Double Overvoltage Protection (OVP) which functions as a double protection against voltage surges that can damage equipment. If there is an excessive voltage surge, the output will be turned off (disconnected) automatically to protect loads.

- Wide Temperature Range (-40°C to +75°C) that can operate well in very low or very high ambient temperatures.

- It has a Static Boost of up to 125% continuously and a Dynamic Boost of up to 200% for a few seconds for starting heavy loads such as large motors or equipment that require a large starting force.

- Preventive Function Monitoring with Configurable Signal Thresholds for early detection when in critical condition and before fatal damage occurs. Thresholds and signal curves can be customized according to application needs for precision monitoring and appropriate preventive action.

These are three important differences between industrial and conventional Power Supply that we review in terms of function, technology and advantages.

In short, industrial Power Supply has a very complex function, more than just providing stable voltage to various electronic equipment in manufacturing.

Industrial Power Supply also serves to protect equipment from damage due to electrical interference, and is equipped with a protection system so that it is not prone to failures that have the potential to pose a safety risk to humans, machines and the environment.

The Critical Role of Industrial Power Supply for Digital Factory Sustainability

Digital Factory is the goal of digital transformation of manufacturing by fully integrating Information Technology (IT) and Operational Technology (OT).

The concept of Digital Factory is to connect people, industrial processes, machines and technology in a sustainable manner, thus creating data-driven integrated manufacturing.

Through full technology integration, the efficiency of every process in the industry can be optimized to achieve carbon-neutral production without compromising economies of scale and production quality.

High reliability industrial power supplies are crucial to ensure efficient energy consumption in the sustainable digital manufacturing sector.

Industrial power supplies are the bridge that connects physical and digital infrastructure, from automation systems in manufacturing to digital infrastructure.

We summarize the contribution of the Power Supply industry to the sustainability of the Digital Factory in the following points:

- High efficiency of over 95% ensures very little energy is lost, resulting in more economical operation, less heat and minimal carbon emissions.

- Connecting physical infrastructure (electronic equipment and machines) in industrial automation systems to digital networks (data, monitoring and cloud), through reliable system availability.

- Carry out monitoring and safety functions to minimize potential hazards from industrial processes in the most vital sectors.

- Minimize financial, personal and environmental losses caused by voltage changes due to system failure or environmental factors (temperature, lightning, dust or vibration).

- Provide power reliability to critical parts of manufacturing and system availability to avoid unplanned downtime.

- Reduce energy and maintenance costs, and maximize system uptime to improve economies of scale.

The integration of advanced industrial power supplies into the Digital Factory ecosystem has many benefits. At the same time, the Digital Factory ecosystem relies heavily on optimal Power Reliability to realize the Net Zero Factory and 1.5°C targets as in the Paris Agreement.

By integrating high-tech industrial power supplies, System Availability can reach the most optimal level to realize a sustainable Digital Factory.

Industrial Power Supply to Ensure System Availability in Manufacturing

Industrial power supplies have far superior stability, reliability and durability than conventional types. The important benefits of industrial Power Supply are as we summarize in the following 4 points:

- Provides stable voltage according to the needs of electronic devices and equipment in manufacturing.

- Protects industrial equipment from damage due to electrical disturbances or voltage surges to prevent downtime and system failure.

- Has a protection system according to international standards so that it is not prone to failures that have the potential to cause safety risks to humans, machines and the industrial environment.

By fulfilling the three functions as we have mentioned above, industrial Power Supply can ensure reliable system availability for business and manufacturing sustainability.

PT. Bawalaksana Central Industrial is an Authorized System Integrator and Solution Partner for Phoenix Contact which is the best industrial Power Supply vendor based in Germany.

We have complete access to Phoenix Contact’s entire product portfolio, including Power Supplies, DC/DC Converters, Redundancy Modules and Uninterruptible Power Supplies (UPS).

Through advanced innovation and expertise in Electrification, Networking and Automation, Phoenix Contact is the best vendor for any Power Reliability and System Availability solution in the Smart Manufacture sector.

If you’re looking for an extensive range of full-featured, state-of-the-art and reliable industrial power supplies, you’ve come to the right place. We can provide comprehensive support from planning, implementation to maintenance.

Talk to our team of Application Engineers to get the best solution. Click the consultation button below to start talking to our team of professionals.

Piko Prasetyo

Application Engineer

This article was written in collaboration with Piko Prasetyo, an expert in Automation, Embedded Systems and Artificial Intelligence, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)

![Problems with 3 Phase Contactors and How to Solve Them [Practical & Effective]](https://bawalaksana.co/wp-content/uploads/2025/07/Masalah-Pada-Kontaktor-Motor-3-Phase-dan-Cara-Mengatasinya-Bawalaksana-ID-1080x675.jpg)