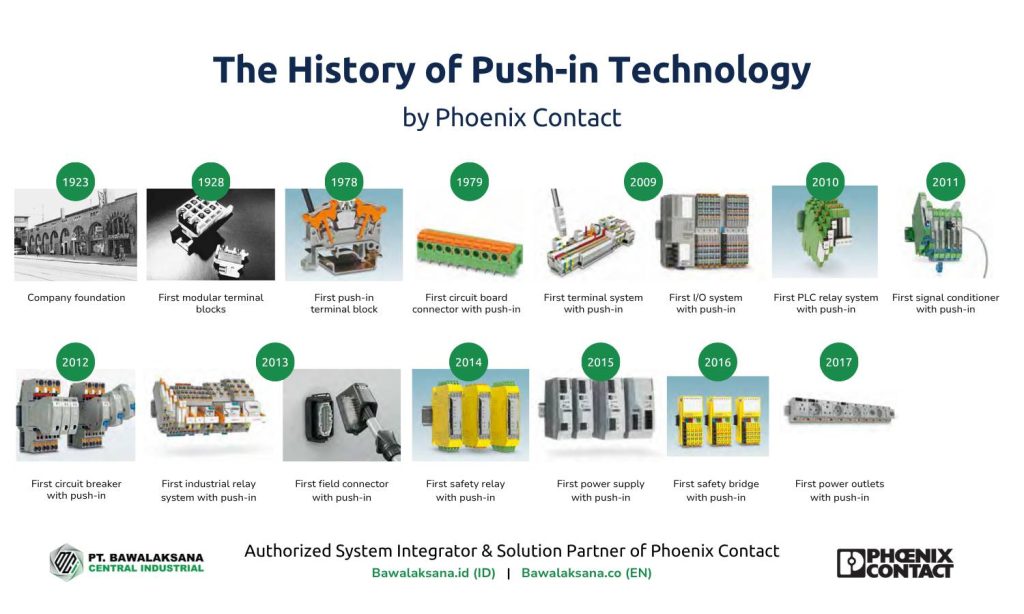

Terminal Block technology has evolved significantly since Phoenix Contact introduced its first product in 1928. The company went on to become a pioneer in electrical connection technology that is now widely used in various industrial sectors.

As is well known, modern electrical installation systems require connection methods that are fast, reliable and highly scalable.

Push-X Technology is the latest innovation from Phoenix Contact that can answer these needs. It provides a tool-less wiring system that drastically reduces installation time.

This technology also contributes to a significant reduction in insertion force, thus contributing to reducing operator fatigue during the installation process.

Push-X terminal blocks support impressive technical specifications, with conductor cross-sections ranging from 0.75 mm² to 25 mm², currents up to 76 A and voltages up to 1000 V.

On this occasion, the Bawalaksana.id team would like to discuss the benefits and advantages of Phoenix Contact Terminal Block in outline.

In this article, we would like to discuss in more detail the technology found in Terminal Blocks, especially the innovations created by Phoenix Contact as a manufacturer with expertise in Electrification, Networking and Automation.

On this occasion, we would like to focus on the Push-in Technology found in the Terminal Block that has been used in the electrical panel wiring process for more than 47 years (since 1978).

What is a Terminal Block and What are its Benefits?

Quoting from Digikey, a terminal block is a tool that functions as a modular electrical system connector and provides a safe and reliable interconnection. Terminal blocks can isolate various electrical cable lines (multiple wires) in one housing so that power distribution becomes easy and effective.

Please note that electrical terminal blocks generally consist of various main components, such as:

- Insulated Frame: A frame that does not conduct electricity.

- Current-Carrying Element: The part that serves to conduct electric current, can be made of copper, brass or other conductive metals.

- Clamping Component: It is a clamp that can hold the electrical cable in place so as to create a good electrical connection between the cable and the conductive part inside the terminal block.

Functions and Benefits of Terminal Blocks

Terminal blocks serve to create quick interconnections for connecting and managing electrical wiring within an electrical panel or cabinet.

This block serves as a central connection for the electrical system of a system, construction, infrastructure, security or automation for the modern industrial sector.

Electrical terminal blocks provide a method for organizing wiring connections safely, quickly and reliably. It consists of components that are modular (can be disassembled) and at the same time become the main hub for power lines in a system.

This terminal block technology has been around for more than a century. Broadly speaking, it has a vital function to make electrical-related settings, maintenance and troubleshooting easier.

Terminal Block Applications in Various Industrial and Commercial Sectors

Terminal blocks are becoming mandatory for every industrial and commercial application involving electrical systems. Its implementation can be found in some critical facilities as follows:

- Manufacturing

- Plant industrial automation system

- Marine environment (marine fleet and ecosystems)

- Mining and oil drilling operations

- Modern transportation infrastructure and lighting

- Aviation infrastructure

- Building infrastructure

The following are some of the benefits of terminal blocks application in various sectors:

- Power Distribution: Distributes the flow of electricity from the energy source to various equipment, machines and systems.

- Industrial control: Used extensively to connect motors, sensors and automation system components.

- Building Infrastructure: Plays an important role in channeling energy for the HVAC system, as well as connecting sensors and actuators that are tasked with regulating the indoor temperature to be within predetermined limits.

- Transportation Systems: Has critical functions to manage traffic lights, traffic signals, railway systems and airport lighting.

- Renewable energy: Used in electricity systems for renewable energy infrastructure that utilizes sunlight or wind. Its main role is to organize energy distribution safely and effectively.

Advantages of Phoenix Contact Terminal Blocks

Phoenix Contact terminal blocks have several important advantages in improving efficiency and reliability in the industrial sector, especially in the aspect of electrical connections.

Push-in Technology was introduced in 1978 and continues to be used today. This connection innovation for terminal blocks offers complete flexibility that allows various types of electrical connections in the industrial sector to be freely combined in one system.

These innovations are essential and valuable when you want to create industry-standard electrical installations that can adapt to a wide range of technologies and meet the latest industry requirements.

The following are some of the advantages of terminal blocks using Phoenix Contact’s Push-in Technology:

- This terminal block design is equipped with a double function shaft, so that it can bridge between one terminal point and another.

- There is a testing feature through several integrated test points, so there is no need to remove conductors or bridges when troubleshooting. This feature can save a lot of time when maintenance is performed.

- It has excellent long-term durability in the face of various environmental challenges.

- It has consistent quality that exceeds industry standards, thanks to comprehensive testing during the production process.

Push-in Technology, an Essential Feature for Terminal Blocks from Phoenix Contact

Phoenix Contact developed the Push-in Connection system which is useful for simplifying the wiring process on terminal blocks.

Push-in Technology provides a significantly easier installation experience.

This technology operates on the simple principle that the mechanical function is separate from the electrical function. The benefit of this technology is to provide a reliable connection without the need for special equipment or training.

There are currently two types of Push-in technology on the Phoneix Contact terminal block, namely:

- Push-in Connection: Began to be used in 1978 and required a ferrule to make the connection on the cable.

- Push-X Connection: Starts to be introduced in 2024 and can accept cables with or without a ferrule.

The following are some of the important benefits of the Push-in Technology feature on Phoenix Contact’s terminal blocks:

Tool-Free Wiring and Airtightness to Meet Extreme Environmental Challenges

Terminal blocks from Phoenix Contact not only offer convenience in making electrical wiring connections. But also to provide good reliability and durability to deal with extreme and corrosive environments.

This terminal block uses solid conductors or wires with crimped-on ferrules that can be inserted directly into the clamping point until it reaches the stop. It’s safe and without any special tools to do so.

Moreover, such features can provide a high level of safety and durability with what is called a gas-tight connection. The resulting electrical connection is therefore gas-tight, and prevents air or moisture from entering the connection.

In the latest series, Push-X Technology, it can accept various wired sizes with or without ferrule. This latest innovation from Phoenix Contact provides many advantages such as ergonomy, safety and broad compatibility.

Conductor Compatibility in the Range 0.34 mm² to 185 mm²

Terminal blocks from Phoenix Contact offer an amazing range of advantages in the realm of conductor acceptance. Because it can accept various cable sizes and types in the range of 0.75 mm² to 25 mm², such as solid cables, flexible cables with ferrules or twisted cables (for Push-X Connection).

Meanwhile, for the previous technology, Push-in Connection, conductors using ferrules are available in a range of 0.34 mm² and up to 185 mm².

There is no doubt that Phoenix Contact’s Push-in Technology for terminal blocks provides ease of use, safety, and effectiveness in terms of implementation and maintenance.

At the same time, this terminal block also has very wide compatibility. That way, the need for many different types of connections for a single installation can be minimized.

Insertion Force Decreases Significantly

Unlike the traditional spring solution, the terminal electrical block from Phoenix Contact does not require a large amount of force to make connections and connect wires.

Therefore, it can be said that the insertion force decreased by 50%. This is because the spring solution that clamps the wires to the terminal block is not too hard.

Even the smallest flexible conductor can trigger splicing. So that the clamp inside the terminal block can be triggered easily to lock the connection quickly, without requiring significant force to press.

This is important, as less labor is required by the engineer in the installation process. That way, the installation of electrical connections becomes easier and reduces fatigue on operators or engineers when working on projects.

| Also Read: Industrial Wireless Communication: Cordless Industrial Automation and Coding With Radioline |

Advantages of Push-X Technology on Phoenix Contact Terminal Block

Push-X Technology is Phoenix Contact’s latest generation conductor joining method and it is a game changer in the terminal block sector. This innovation offers a number of significant advantages over conventional terminal block technology and previous generation connection types such as screw, spring cage and push-in terminals.

Here are the main advantages of Push-X Technology based on official sources and the latest technical explanations:

Making Connections with No Tools and No Effort

Push-X Connection enables tool-free direct cabling for both solid and flexible cables, with or without ferrules. With just a slight push on the clamping chamber, a solid connection can be obtained.

Very fast installation process

Terminal blocks with Push-X Technology have clamping chambers that are already open and ready to accept conductors to make a solid electrical connection. With a slight push on the clamp chamber, electrical conduction can be created.

With these advantages, it will contribute to a quick and practical installation time.

Push-X Technology for this terminal block is touted as one of the fastest for flexible cabling, as it only requires minimal preparation of the cable (just use stripping pliers).

Visual and Acoustic Indications

Visually, the orange push button can be seen in the open or closed position.

Meanwhile, when the cable is inserted, there will be a “click” sound to indicate that the clamping spring is active. This provides acoustic feedback that the connection has been successful and a solid connection has been established.

Easy and Safe Cable Removal

To disconnect the cable, simply press the push button (orange in color). When the cable is removed, the clamping spring automatically returns to its initial (open) position and is ready to accept connections from the cable without any additional processing.

Efficiency and Ergonomics

The wiring process becomes more efficient with Push-X Technology, reducing installation time and technician fatigue due to repetitive motion. This is especially beneficial for mass work or in labor-intensive production environments.

Compatible for All Cable Types

Push-X Connection can accommodate all types of conductors, whether rigid or flexible, with or without ferrules. Even flexible cables with very small cross-sections can be connected easily and safely, as long as they are within the range of 0.75 mm² to 25 mm².

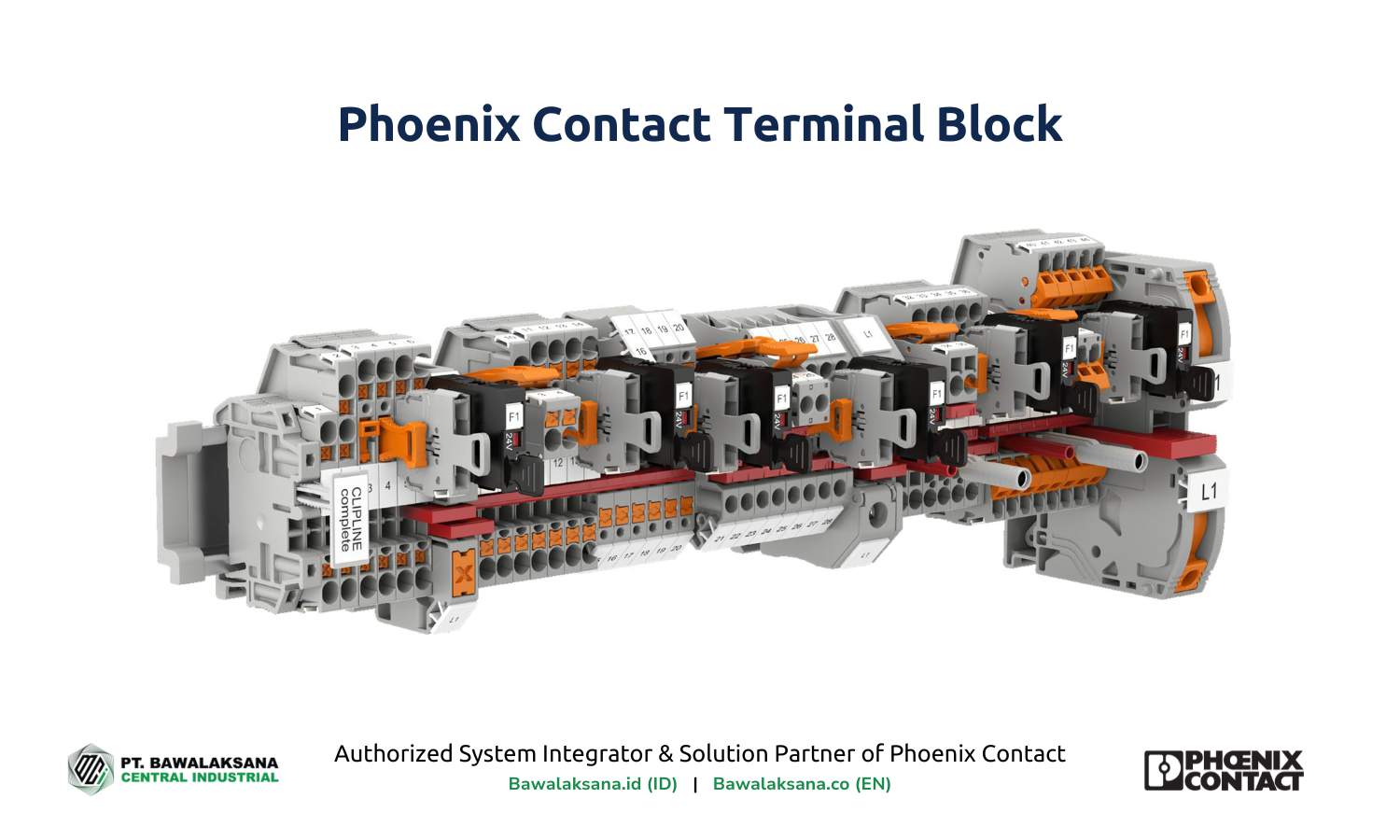

System Flexibility and Compatibility

Push-X Connection is fully integrated with Phoenix Contact’s CLIPLINE complete terminal block system. This allows the use of various standard accessories such as fuse plugs, disconnect knives and other components.

Push-X is also compatible with various types of terminal blocks (feed-through, multi-level, knife-disconnect and others so that it can accommodate various needs in various industrial sectors.

Ready for Automation

The advantage of Phoenix Contact’s Push-X Technology is its readiness for both manual and automatic installation. This innovation opens up a wide space for various wiring needs in industries that have implemented automation in making electrical panels.

In conclusion, Phoenix Contact’s Push-X Technology revolutionizes terminal block connections by combining speed, ease, flexibility and safety of wiring. All the advantages that we have mentioned above deliver Push-X Connection as the best solution for various modern and sophisticated industrial applications.

PT. Bawalaksana Central Industrial is an authorized system integrator and solution partner for Phoenix Contact that can provide a complete solution for your company. We can help you from planning, installation to ongoing maintenance.

We provide comprehensive support for the implementation of the latest technology from Phoenix Contact. That way, your company can adopt the latest innovations that are modern and smart.

As we have mentioned in this article, terminal blocks from Phoenix Contact have many benefits in critical and demanding industrial sectors.

Conductor connections with vibration-resistant and gas-tight connections can eliminate common maintenance problems with terminal blocks.

The good news is that Phoenix Contact continues to innovate and develop connection technology to answer every challenge in various industrial sectors. Good for control panels, power distribution systems and industrial automation solutions.

Terminal blocks from Phoenix Contact offer an optimal balance between ergonomy, efficiency, safety, dependability and compatibility.

Start creating reliable electrical installations through reliable connections. Please contact the Bawalaksana.id team now for comprehensive support.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)