Entering the digital era and smart industry today, data acquisition of various parameters in the industry has become very critical. Especially when it comes to security, safety and productivity. That’s why Industrial Wireless Communication is important for manufacturers to have.

At the same time, the cabling system in the industrial sector today is very complicated. Adopting new technologies that are still wired for data acquisition at some points in the industry, seems to be a nightmare because it is difficult to implement.

Hence, there is a need for advanced technology that can simplify the process of implementing and collecting data for various parameters in the industrial sector.

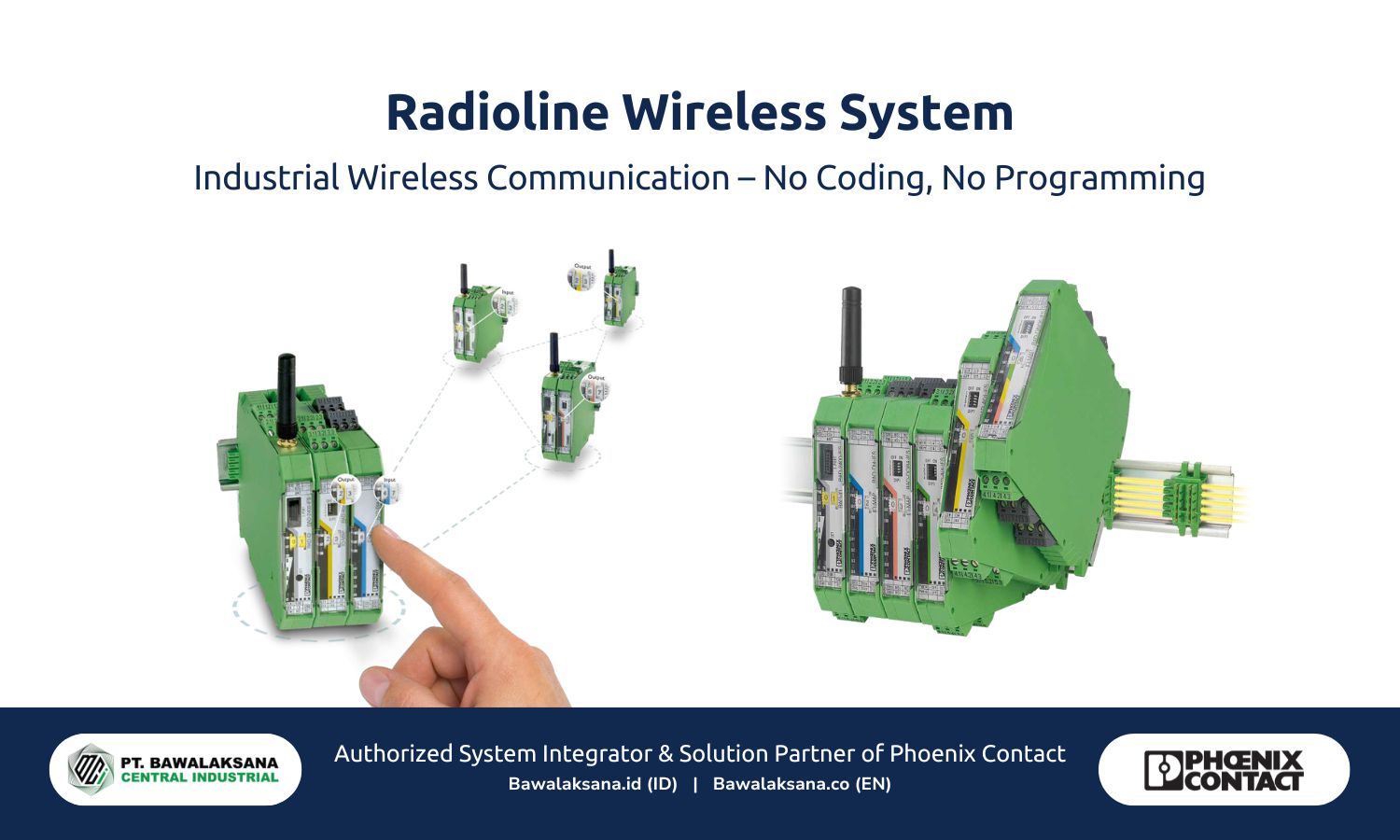

The best solution is to use Radioline Wireless System technology as one of the Industrial Wireless Communication technologies that can be used for communication without cables, without coding in the manufacturing sector.

In this article, the Bawalaksana.id team would like to discuss the importance of implementing Wireless Communication devices in critical and complex industrial sectors.

That way, a team of engineers in the industry can perform data acquisition and run industrial automation easily and practically.

What is Industrial Wireless Communication and its Benefits for Manufacturing?

Efficiency, cost and productivity are the main reasons why Industrial Wireless Communication technology has become so important in the digital era.

At the same time, factories and industrial facilities are generally saturated with complex legacy cable installations. In fact, an inhibiting factor for implementation can be incomplete or even unavailable Single Line Diagram (SLD) documentation.

Therefore, when factories want to adopt new technologies using wired systems for automation systems and parameter acquisition in industry, it seems impossible to realize.

So this is where the importance of Wireless Communication Technology to simplify the implementation process and work efficiency of the engineer team in the industry.

By utilizing wireless communication technology in the industrial sector, factories can perform data transmission or data acquisition quickly and effectively, as well as control for various systems without using physical cables. This contributes to efficiency, productivity, flexibility and convenience in various aspects.

The important benefits of Industrial Wireless Communication for manufacturing are as follows:

- The implementation of the technology does not require a large workforce, as there is no need to create new cabling lines. This will not increase the workload of the engineer team who work in shifts.

- Installation costs and time are very low as there is no need to purchase long cables. So that the implementation process is more effective and downtime is minimal.

- It can be deployed at multiple points up to 32 KM wide using the 2.4 GHz frequency with low latency, and with individually adjustable receiver sensitivity and data rate.

- Support easy and reliable digital transformation, and support data-driven decision making.

- Easy integration and can minimize the risk of disruption to the existing system.

By using Wireless Communication Technology, the implementation of new technologies for automation systems and the acquisition of various parameters in industry has become easier.

You don’t have to worry about problems with existing systems or complicated processes in integrating with this wireless communication technology.

Radioline Wireless System for Cordless Communication

Adopting wireless communication systems in the industrial sector is a common practice. This is like the transition from landlines to cell phones.

One of the wireless technologies for communication systems in the industrial sector is to use radio-based communication devices (RF). The advantage of this technology is that it does not require subscription fees like cellular phones.

However, radio-based technologies can also offer good data rates for data collection across various sensors in industrial fields.

Phoenix Contact’s Radioline Wireless System is one of the best technologies for wireless communication systems in the industrial sector that we highly recommend.

Radioline is a wireless system for large and extensive communication systems in the industrial sector (up to 32 KM and up to 32 modules).

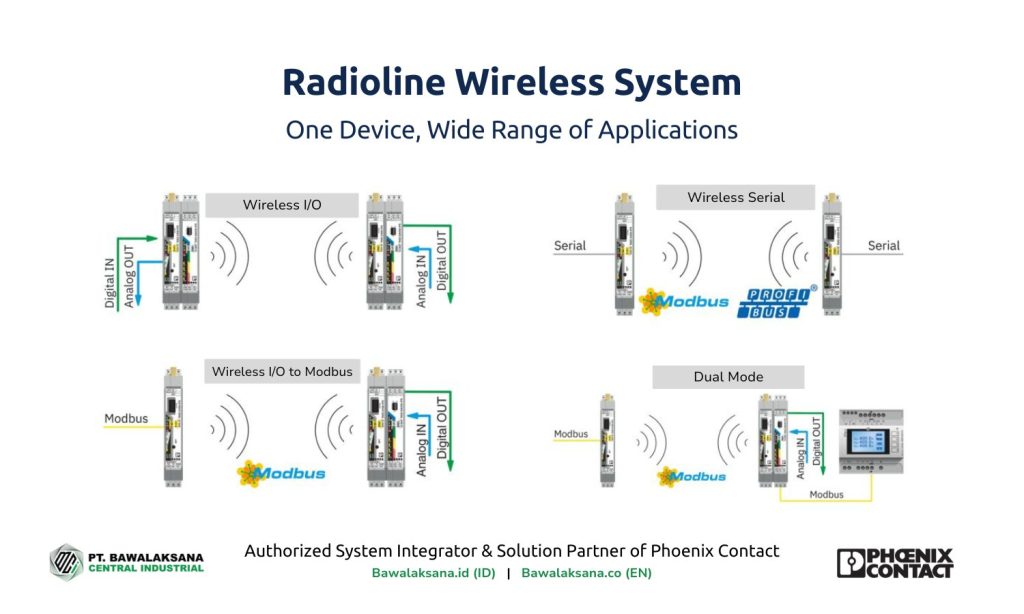

This device has various excellent features, including distributed I/O system settings, and can perform input and output communication wirelessly without coding and without programming.

With these advantages, the Radioline Wireless System can be relied upon as an ideal solution for the implementation of industrial automation systems and data acquisition at various points in the factory or manufacturing.

Pros of Radioline Wireless System

Phoenix Contact’s Radioline has the tagline, “One device for multiple applications”. This is certainly not an exaggeration, as Radioline devices allow for easy distribution of I/O signals across a designated network.

Radioline also supports various types of expansion modules, including analog modules for 4-20 mA or 0-10 V signal acquisition commonly used in pressure, temperature or level measurement.

In addition, there is also a digital input module for receiving on/off signals from devices such as push buttons, as well as a digital output module that can be used to control loads such as three-phase induction motor contactors.

The following are some points about the advantages and benefits of the Radioline Wireless System from Phoenix Contact:

I/O Mapping

The process of mapping or connecting between Radioline devices is very easy by turning the thumbwheel (small number wheel on the module) to set the address (IO MAP Address).

By setting the same address, devices can communicate with each other in a network with a distance of up to tens of kilometers.

In simple terms, the process of setting the IO MAP Address on Radioline is as follows:

- Set the digital input module to address 12

- Then set the digital output module that you want to receive the signal to address 12 as well.

- As a result, signals from inputs will automatically be forwarded to output modules that have the same address without the need for programming.

- You can also set up more than one output module using the same address to communicate with input modules.

It should be noted that the Radioline signal can be expanded with up to 32 I/O modules as it has DIN rail connectors and hot-swap capability. In addition, sending I/O signals or serial data uses a single device, as it has an integrated RS-232/RS-485 interface.

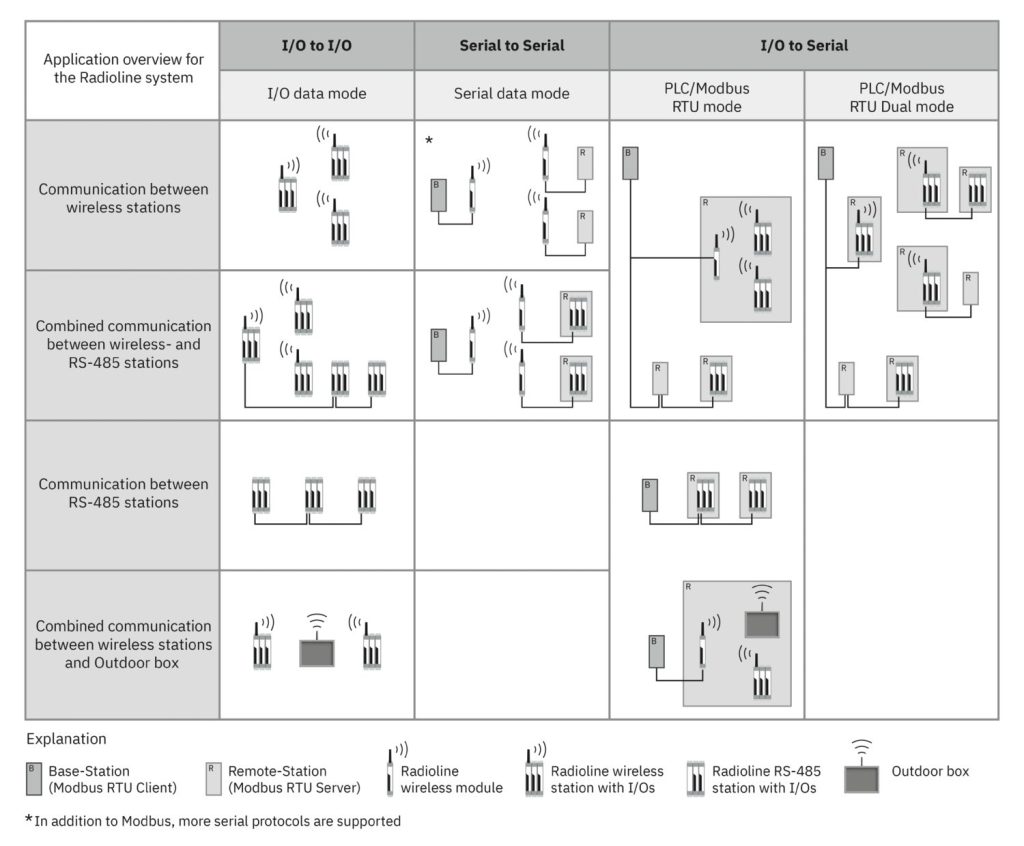

I/O Data Mode

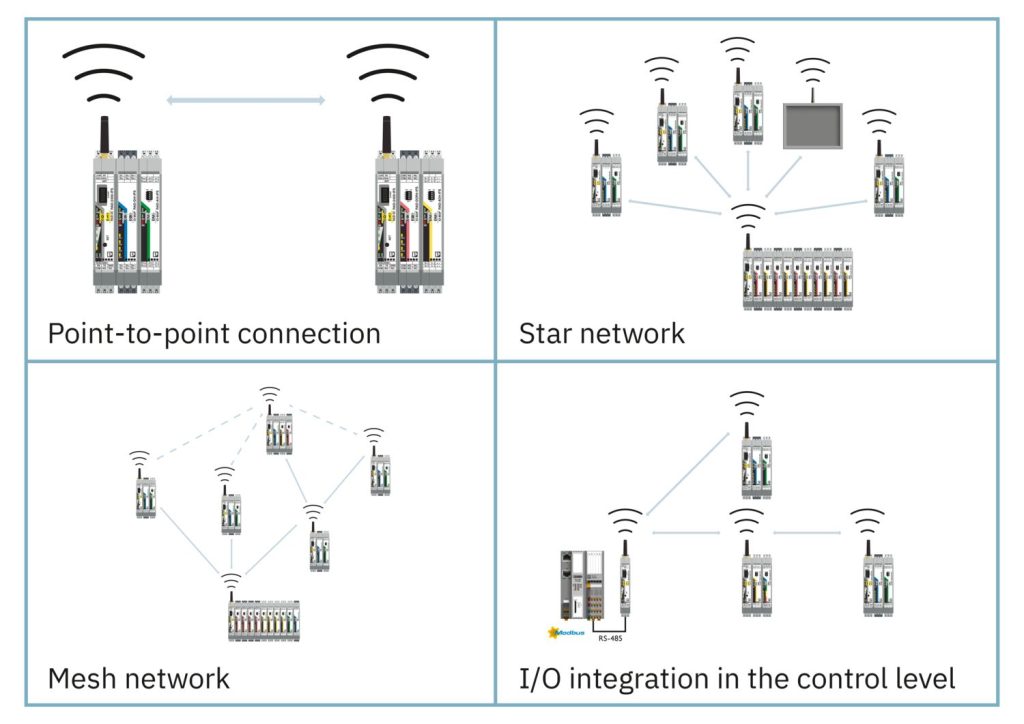

With the ease of setting the IO MAP Address, Radioline Wireless System helps in easy distribution of I/O signals across the network. This advantage also supports data distribution to various network structures (topologies) in the industrial sector.

Radioline supports mesh topology as well as star topology. As such, this technology is ideal for application in industrial environments that require data acquisition from machines or sensors spread over a wide area. Even in open areas with long distances between points.

Therefore, Radioline makes it easy to distribute I/O signals in large systems effectively and practically. By turning the thumbwheel to set the input and output addresses, signals can be routed and multiplexed to various points.

Serial Data Mode

Another important advantage of the Radioline Wireless System is that it can be used to connect multiple controllers or serial I/O devices quickly and easily.

With this advantage, you can replace RS-232/RS-485 cables with industrial-grade wireless communication tools, such as Radioline.

It can connect multiple controllers or I/O devices without physical cables, reducing the cost and complexity of wiring installations in the factory.

PLC/Modbus RTU mode

If sensors in the field can communicate using Modbus RTU or Modbus ASCII, Radioline from Phoenix Contact can be used directly to pull sensor data without the need for additional protocol converter modules.

This helps minimize unexpected costs and keep the project timeline on track.

Radioline supports both protocols through RS-232 and RS-485 interfaces, making it suitable for modern sensor systems as well as RS-232 and RS-485-based legacy devices.

With proper configuration using PSI-CONF, integration of legacy devices using Modbus ASCII can be done easily and efficiently.

In addition to the signal, diagnostic parameters such as the signal quality of each device are also provided in the Modbus registers. This is beneficial to ensure continuous monitoring of the Radioline wireless system.

PLC/Modbus RTU Dual Mode

This mode can combine “Serial Data Mode” and “PLC/Modbus RTU Mode”. By using PLC/Modbus RTU Dual Mode, each station in the network acts as an independent Modbus server.

In addition, you can also connect an I/O extension module to each station in the network. Furthermore, the process data will be stored locally in the Modbus memory map for each station.

At the same time, additional Modbus servers can be connected to each station via RS-232 or RS-485 and addressed via their respective Modbus addresses.

Then, you can also read all the wireless network diagnostic data from the wireless base station via Modbus.

No Special Licenses Required to Government Agencies

In Indonesia, the commonly used free radio frequency for industrial communications is 2.4 GHz. Similarly, Radioline operates on this frequency, so you don’t need to do any special reporting or licensing to government agencies.

Radioline’s industrial communication devices do not interfere with the radio frequencies used by government divisions that use remote communication devices.

It should be noted, however, that the Radioline communication network has very high reliability, as it has several advantages such as:

- AES Encryption

- Hopping frequency

- Coexistence management

- High receiver sensitivity

- Wide range of up to 32 KM

- Expandable with up to 32 I/O modules

- Latest generation Trusted Wireless 2.0 technology

- Individually adjustable data rate

Radioline Wireless System Applications in Various Industrial and Commercial Sectors

Radioline Wireless System can be used in various sectors in critical and commercial industries, such as traffic signaling systems, power generation and waste treatment.

The following are some of the sectors that can implement Radioline Wireless System and its benefits in brief:

Process Technology

In this sector, Radioline can be used for various important functions, such as the following:

- Tank fill level monitoring

- Pumping stations and well chains

- Pipeline network monitoring

- Chemical plant infrastructure

- Leak monitoring

- Flow rate measurement

- Temperature monitoring

- Energy management

- Ex zone 2 areas

Water and Sewage Treatment

In the water and waste treatment sector, Radioline can be used for:

- Water treatment plant

- Remote well connection

- Remote pump station connection

- Rotating components (such as scraper bridges)

- Fill level monitoring

Energy Technology and Energy Conveyors

In the energy technology sector, Radioline can be used for:

- Windmill area

- Surface mining

- Transformer station

- Power generation infrastructure

- Hydroelectric power plant

In the energy conveyor sector, Radioline can be used for:

- Motor monitoring of the conveyor belt

- Error messages and status messages on moving automated vehicles

Transportation Technology

In the transportation and traffic sector, Radioline serves to:

- Light signal system control

- Set up displays in the car park

- Variable traffic signage system

- Traffic signs

| Also Read: Integration of Artificial Intelligence (AI) in Industrial Automation with PLCnext Technology |

Start of Implementation of Industrial Wireless Communication with No Wires and No Coding

It is important to recognize that Industrial Wireless Communication technologies such as Radioline have become vital in the Industry 4.0 era and the Digital Factory ecosystem.

In today’s modern era, data acquisition is a must-do for engineers in the industry. So that industry and manufacturing can achieve the most optimal level of efficiency and productivity.

At the same time, the plant infrastructure has become so complex that it is challenging to implement technologies to collect various parameters in the industry.

Radioline Wireless System is the best solution to overcome the complex implementation of new technologies in various industrial sectors.

Radioline can be applied in various sectors easily and practically. No wires, no coding and no special programming skills.

By simply setting the input and output modules using a thumbwheel, a number of Radioline devices can communicate in a single network over great distances.

PT. Bawalaksana Central Industrial is an authorized system integrator and solution partner for Phoenix Contact. We can help your company to integrate Radioline Wireless Communication into your existing system.

As an authorized solution partner, we also sell the latest technologies and innovations from Phoenix Contact. We offer complete support from planning, implementation, to ongoing maintenance.

If you are interested in adopting all the modern technology from Phoenix Contact, you can collaborate with us to get the best service and support.

Please connect with our professional team now, by clicking the Contact Us button below.

Piko Prasetyo

Application Engineer

This article was written in collaboration with Piko Prasetyo, an expert in Automation, Embedded Systems and Artificial Intelligence, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)