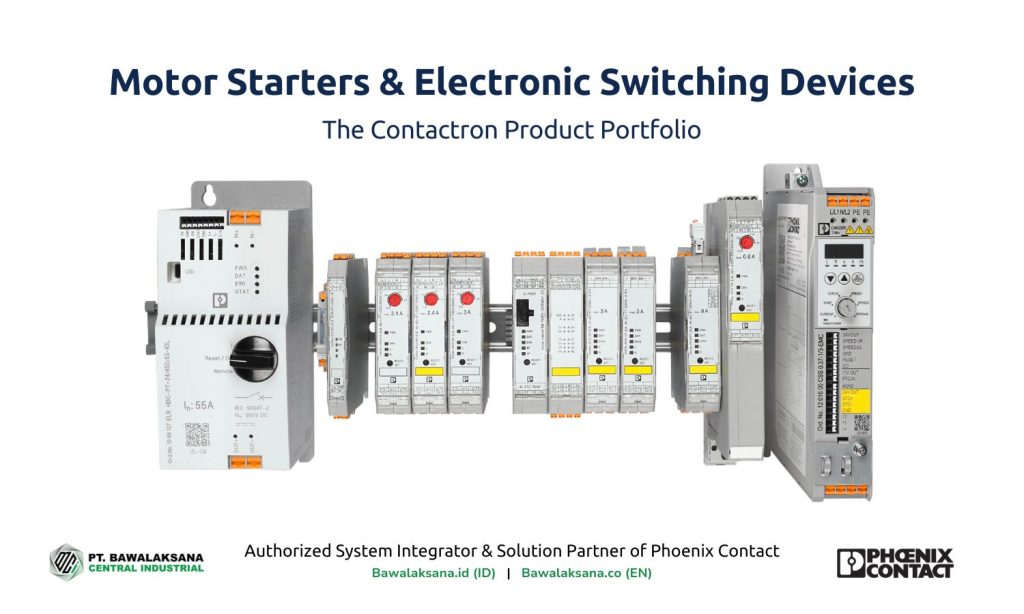

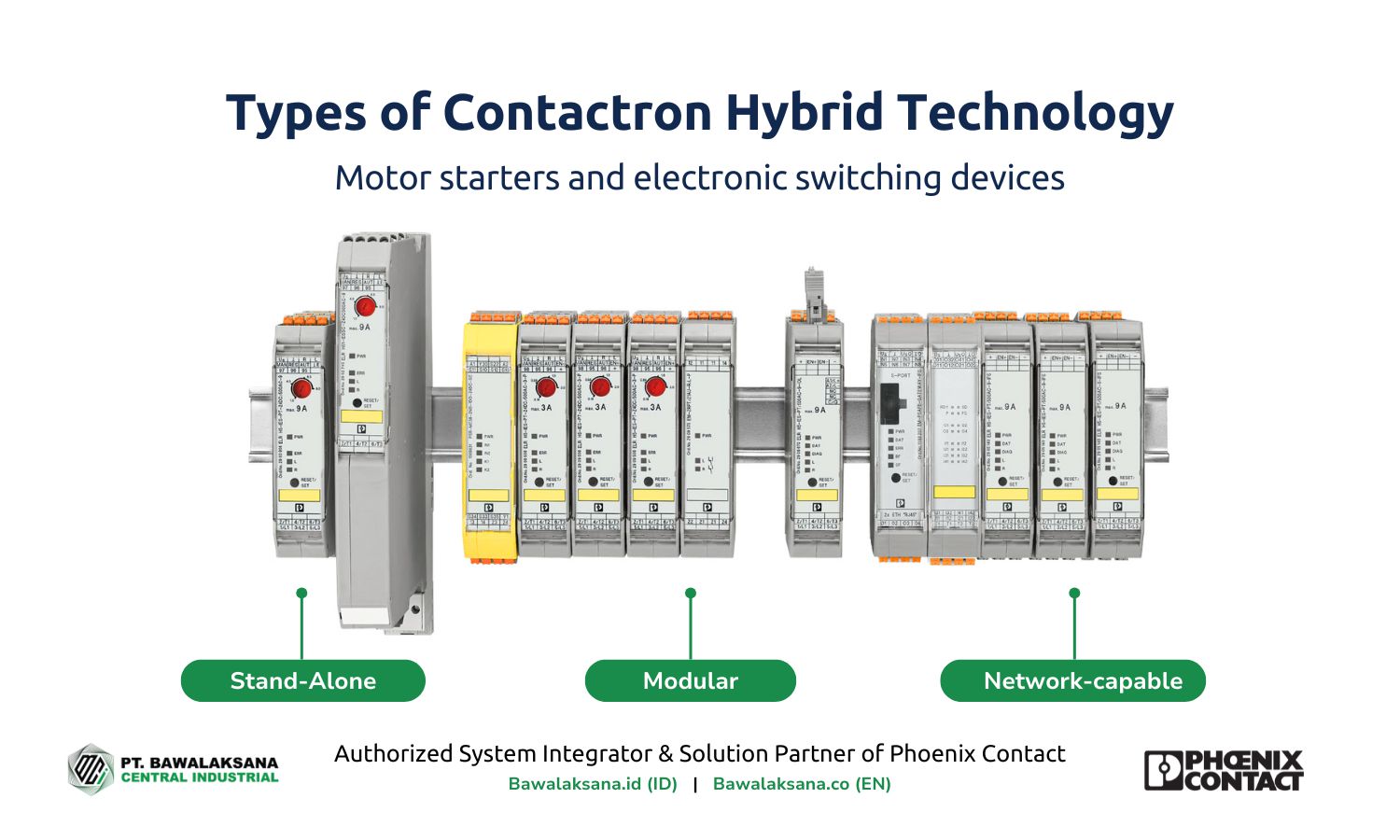

The electrical contactor is an important component that functions to regulate the 3-phase motor working system so that it can operate safely, effectively and energy-efficiently. It is generally available in three main type groups, including:

- Stand-Alone Motor Starter

- Modular Motor Starter

- Network-Capable Motor Starter

Electrical contactors are responsible for preventing damage to 3-phase motors that use large power, so they do not experience overloads or short circuits that can cause severe damage.

In the previous article, we discussed Problems that Often Occur in 3 Phase Contactors and How to Solve Them.

In the article, we have explained several things that cause contactors to malfunction easily and how effective solutions to overcome these problems are.

In this article, the Bawalaksana.id team would like to discuss two important things as follows:

- Types of 3-phase electrical contactors that use hybrid technology

- Disadvantages of conventional 3-phase electrical contactors that use electromagnetic coils

Let’s take a look at the full discussion below!

Disadvantages of Conventional Electrical Contactors

Before discussing the types of electrical contactors that use hybrid technology, we first need to inform the problems and shortcomings that are generally found in conventional (mechanical) electrical contactors.

Here are some weaknesses in conventional contactors that use electromagnetic coils:

- Relay heats up quickly and is damaged due to high switching frequency

- The switching mechanism is prone to sparks, which makes the contactor quickly wear and damage

- Short service life (breaks down quickly) due to relatively low switching cycles

- Electromagnetic coil and moving mechanical parts inside the contactor are easily damaged due to vibration

- Has a complex wiring system and schematics, making maintenance and troubleshooting difficult.

- To meet the high industrial demand, additional complex components such as reversion contactors, protection relays and additional safety switching devices are required.

- Larger size and requires more panel space

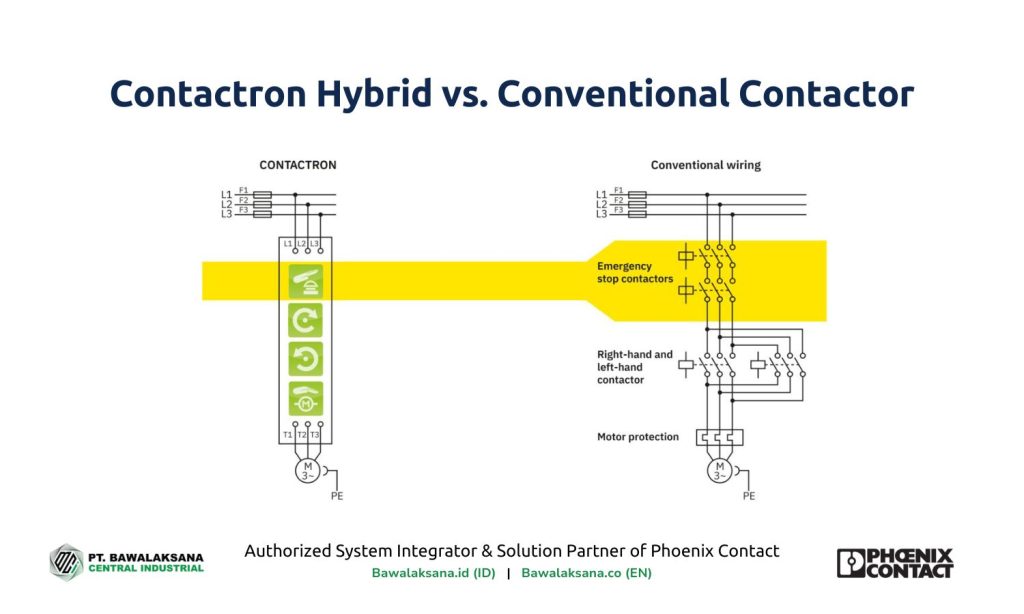

The following diagram is a schematic comparison between Hybrid Technology contactors and conventional contactors that use electromagnetic coils.

As we mentioned earlier, electrical contactors play an important role in regulating the operation of high-voltage 3-phase motors. Therefore, when the electrical contactor is easily damaged or disturbed, the operation of the 3-phase motor is also not optimal.

Conventional contactors with low quality can cause various problems in 3-phase motors, such as:

- Reduced engine performance

- Malfunction

- Permanent damage

Thus, using conventional contactors requires extra attention so that they last longer and the risk of severe failure can be avoided.

Realizing how crucial the role of electrical contactors is in operating 3-phase motors safely and effectively, using contactors with Hybrid Technology can be the best decision so that factory productivity reaches the most optimal limit.

The following Bawalaksana.id team will mention some of the most common types of contactors with Hybrid Technology along with their benefits and advantages.

The types of contactors with Hybrid Technology that we mention here refer to Phoenix Contact’s Contactron Hybrid Technology which has a compact design, advanced features and is an important part of the ecosystem. Digital Factory ecosystem.

If you want to know some basic features of this contactor with Hybrid Technology, please visit our previous article.

Stand-Alone Motor Starter

The first type of electrical contactor with Hybrid Technology is the Stand-Alone Motor Starter. This contactor has the main function to turn on, turn off, and change the direction of rotation (reversing) 3 phase motor automatically.

Stand-Alone contactors are available in two types, namely Direct Starter and Reversing Starter.

The Stand-Alone Motor Starter is equipped with emergency stop and motor protection, and has a compact size of 22.5 mm wide and a capacity of 50 W to 3 kW.

This type of electrical contactor is equipped with a replaceable internal fuse, and still offers ease of wiring through optional loop bridge support, even when used separately without a modular system.

Main Functions and Uses of Stand-Alone Motor Starters

- Starting/Stopping the Motor: Controls the electric current to the motor so that it can start and stop safely.

- Reversing Motor Rotation Direction: The reversing type allows the motor to rotate in both directions as required by industrial applications.

- Motor Protection: There is adjustable bimetal protection (up to 9A current) to protect the motor from overload damage.

- Emergency Stop: Features an immediate motor stop in the event of a hazard or emergency condition.

- High Safety Features: Equipped with a shutdown function with maximum safety standards up to SIL 3 and PL e, according to the needs of critical applications such as the automation industry and factories.

Advantages of Stand-alone Motor Starter

- Ultra Compact Design: Only 22.5 mm wide, saving up to 75% space in the electrical panel.

- Easy Installation: The cable locking system and load wiring are integrated, reducing the possibility of installation errors and speeding up the installation process.

- Long Service Life: By adopting Contactron Hybrid Technology, the switching process is very gentle so that it is not easily damaged and the service life is 10 times that of conventional contactors.

- Wide Power Range: Suitable for three-phase motors with a capacity of 50 W to 3 kW.

When to Use Stand-Alone Motor Starters?

- When you need a practical, compact and reliable 3-phase electric motor controller solution for operating motors with power between 50 W and 3 kW.

- If your application requires basic functions of starting, stopping, motor rotational direction reversion and motor protection without the need for communication network integration or digitization.

- In situations where panel space is limited and you need a very compact device (only 22.5 mm wide) to save installation space.

- When you prioritize long life and minimal maintenance, thanks to hybrid technology that extends tool life by up to 10 times compared to conventional starters.

- In industrial applications that do not require connection to a centralized control system or network system, so wiring and configuration can be simpler and more straightforward.

- If motor and operator safety needs to be maintained with adjustable bimetal protection and a safe shutdown feature that complies with high safety standards (SIL 3 and PL e).

In conclusion, the Stand-Alone Motor Starter type electrical contactor is the right choice for operating 3-phase electric motors automatically and effectively. This contactor is easy to install and is equipped with emergency stop and motor protection features.

It can be an economical yet high-quality option for systems that do not require complex industrial automation integration.

We have summarized the advantages of the Stand-Alone Motor Starter in the following table:

| Key Features | Functions and Benefits |

| Compact design | 22.5 mm, saving space on the panel |

| Easy wiring | Integrated key circuit & wiring |

| Long wear life | Soft switching, more durable |

| Motor protection | Bimetal, current up to 9A |

| Safe shutdown | Up to SIL 3 and PL e |

| Capacity | 50W to 3kW |

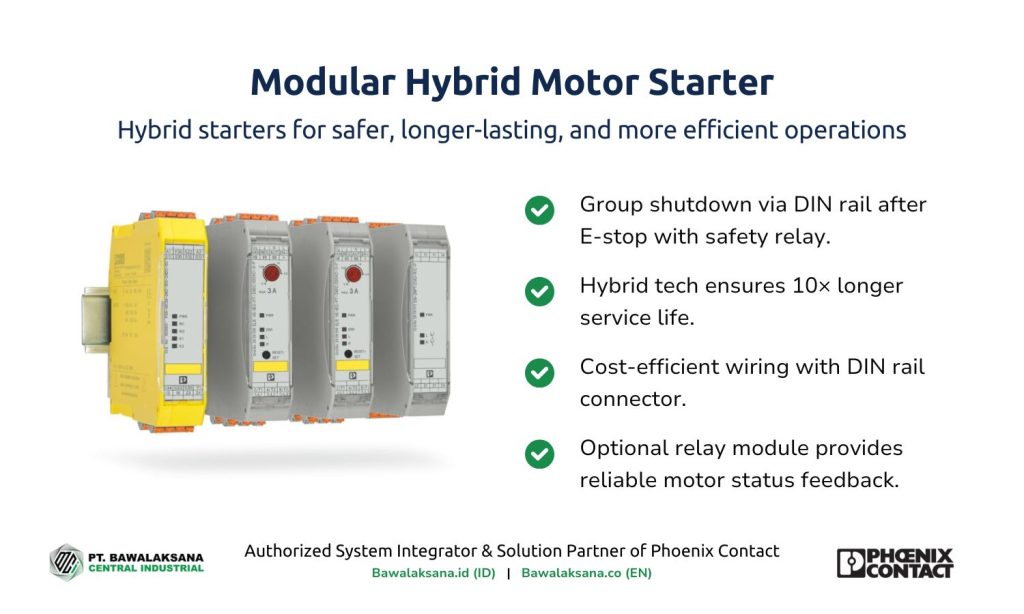

Modular Hybrid Motor Starter

Modular Hybrid Motor Starter is a motor starter with Hybrid Technology that can be modularly arranged on a DIN rail. This means that the starter motor contactor can be developed or added with certain components as needed.

Modular Hybrid Motor Starter is a Contactron Pro product from Phoenix Contact that combines the advantages of mechanical and electronic contacts, resulting in more reliable and long-lasting performance.

Contactron Pro has some key advantages not found in the Stand-Alone type, namely:

- Using the T-BUS as an internal connector allows the distribution of three-phase voltage (RST) directly along the rail, thus minimizing the use of external cables.

- In addition to ease of wiring, this modular type also supports integration with dedicated safety relays, allowing up to 10 hybrid motor starters to be stopped simultaneously through one emergency stop group system.

- For the acquisition of motor direction (forward/reverse) status data by the PLC, there is also an I/O extension module with relay output, which is specially designed so that the status signal can be easily read by the control system.

Main Functions and Uses of Modular Hybrid Motor Starter (Contactron Pro)

- Safe and Modular Motor Control: You can easily integrate this motor starter with safety systems. For example, the ability to shutdown motor groups simultaneously via DIN rail connectors with a command from a safety relay after an emergency stop.

- Flexible and Easy to Develop: Being modular, you can add or change starter functions according to the changing needs of the machine or system, without having to replace the entire device.

Advantages of Modular Hybrid Motor Starter (Contactron Pro)

- Easy Group Shutdown: After an emergency stop, the entire group of connected motors can be shut down together by connecting via DIN rail connectors and safety relays. This advantage can speed up the safety process and minimize risks on the production floor.

- Long Service Life: Hybrid technology gives the starter motor up to 10 times longer service life than conventional starters, reducing the frequency of maintenance or replacement.

- Practical Installation and Setting Process: The economical DIN rail connector system enables fast installation and reduced wiring harnesses, reducing installation costs and time.

- Motor Status Feedback: With the optional relay module, you can get realtime motor status information that is very useful for monitoring and diagnostics. For example, whether the motor is on or off.

When to Use Modular Hybrid Motor Starter?

- When you need a motor starter with higher functional safety to maintain optimal system availability.

- When factory control systems want devices that are easy to expand and customize over time in a modular manner.

- If you need a durable motorcycle starter with minimal maintenance (easy handling).

- Prioritizing space saving, fast installation and requiring realtime motor monitoring features.

In conclusion, the Modular Hybrid Motor Starter contactor (Contactron Pro) is the best solution for modern motor starters that offers easy integration with security systems. This contactor offers flexibility through its modular design, functional safety and long service life.

Contactron Pro is the right choice for industrial applications that require a motor control system that is safe, high durability and offers flexibility.

We have summarized the advantages of the Modular Hybrid Motor Starter contactor in the following table:

| Key Features | Functions and Benefits |

| Modular and extensible | Flexibility in upgrading and adding functions |

| Security System Integration | Rapid group motor shutdown after emergency stop |

| DIN rail connector for quick connection | Faster and cost-effective installation |

| Motor status feedback via relay module | Real-time motor monitoring |

Network-Capable Motor Starter

The Network-Capable Motor Starter is the third type of Hybrid Technology contactor and is the most advanced type. This third type has all the basic features as the two types of Hybrid Technology contactors we mentioned earlier.

Network-Capable contactors can also utilize T-BUS which can function like distributed I/Os with specialization in 3-phase motor actuators.

Please note, that this third type requires a Hybrid Motor Starter device to work properly. So that a gateway is needed as a link to the controller or PLC in charge of controlling the group of distributed I / O devices.

And actually this type is specialized to be an actuator in a group that prioritizes safety, maintainability and large scale implementation. Unlike the previous two groups of types, which are selected in the process of designing smaller systems.

Network-Capable Motor Starters can connect directly to an industrial communication network (fieldbus system), such as the Radioline Industrial Wireless System. As such, it can be integrated with modern factory automation systems, to meet the requirements of Industry 4.0 and manufacturing digitization.

Main Functions and Uses of Network-Capable Motor Starters

- Integration to Automation Systems (Fieldbus): This motor starter is equipped with INTERFACE system connections that can be connected to industrial communication networks through various gateways. These gateways support almost all commonly used fieldbus systems, such as Profibus, Profinet, Modbus and others.

- Easy Transfer of Process Data: You can easily transmit data from the motor starter to the central control system, enabling real-time and more accurate monitoring and control of the motor.

- Save Space and Cables: Since the device can be directly connected to the network, there is less need for cables and dedicated I/O devices in the controller. This will make the control panel installation neater and more practical.

- Diagnostic Functions: This motor starter provides a diagnostic feature that helps detect faults or abnormal conditions in the motor or electrical circuit, making maintenance easier and preventing further damage.

- Data Customization: You can customize the process of sending and receiving data according to the specific needs of your application and industry processes, thus supporting the implementation of Digital Factory with ease.

Advantages of Network-Capable Motor Starter

- Flexible Fieldbus Connection: Simply attach a gateway that matches the fieldbus type and the device is ready to connect.

- 24V Power Supply: The power required for the INTERFACE System (IFS) devices is supplied directly 24 volts without any complicated additional wiring.

- Fast Installation with DIN Rail Connector: Other IFS-based devices can be directly connected with a special latching on the DIN rail, saving installation time.

- No Need for Additional I/O Cards: The Gateway provides 8 digital inputs and 4 digital outputs, replacing the need for additional input/output cards in the controller, thus minimizing the amount of hardware for easier configuration.

When to Use a Network-Capable Motor Starter?

- If you want the motor starter to be able to integrate directly into an automation system or fieldbus-based control system.

- If you need digital and realtime motor monitoring and diagnostics data.

- When space and cable management are important in a control panel.

- In a modern industrial environment that uses the Digital Factory concept.

Protocol Gateway for Network-Capable Hybrid Motor Starter

- PROFIsafe (15 device Contactron/Interface Systems)

- PROFIBUS DP (32 device Contactron/Interface Systems)

- CANopen (32 device Contactron/Interface Systems)

- PROFINET (32 device Contactron/Interface Systems)

- Modbus/TCP (32 device Contactron/Interface Systems)

- EtherNet/IP (32 device Contactron/Interface Systems)

Please note, that contactors with Network-Capable types are available types that have been equipped with IO-Link. So that type no longer requires a dedicated gateway, as it can use the IO-Link master as a gateway.

The following are some of the excellent features possessed by this type of Network-Capable Motor Starter:

| Key Features | Functions and Benefits |

| Start/Stop motor | Turning the motor on or off (direct or reversing). |

| Direction of rotation | Select the forward/reverse rotation direction. |

| Reset command | Reset after a fault (e.g., overload). |

| Enable/Disable motor starter | Enable/disable Contactron. |

For example, with PROFINET, the following bits can be accessed to utilize the Network Capabilities feature of this motor starter:

Control bits (Q area) might include:

- Bit 0: Start forward

- Bit 1: Start reverse

- Bit 2: Reset

- Bit 3: Enable

Status bits (I area) might include:

- Bit 0: Motor running

- Bit 1: Motor fault

- Bit 2: Overload

- Bit 3: Direction feedback

In conclusion, Network-Capable contactor types are well suited for industrial applications that require complete integration to an automated control system. This type of contactor offers ease of monitoring and maintenance, as well as a compact and efficient installation process.

This Network-Capable Motor Starter is a practical and modern solution to connect electric motors into a Digital Factory ecosystem that is energy efficient, high productivity and sustainable.

As a summary for the advantages of Motor Starter contactors with Network-Capable, we have noted in the following table:

| Key Features | Functions and Benefits |

| Integration with fieldbus (INTERFACE) | Connect the starter motor to the automation system |

| Gateway for various fieldbus protocols | Easily fits into various industrial networks |

| Real-time transfer of process data | Better motor monitoring and control |

| Diagnostic features | Detection and prevention of motor failure |

| 24V power supply | Easier and more practical installation |

| Fast DIN rail connector | Speed up device installation |

| 8 digital inputs & 4 digital outputs integrated | Reduce additional controller hardware |

Implementation of Smart Electrical Contactors to Increase Plant Availability in Your Industry

Electrical contactors are an integral part of industrial automation systems for controlling high-power 3-phase motors. This component plays an important role in keeping the performance of the electric motor at its most optimal, safe and sustainable stage.

Investing in high-quality intelligent electrical contactors is the best decision to increase safety and productivity levels on the factory floor.

Phoenix Contact’s Contactron Hybrid Technology offers a broad portfolio to suit the operational needs of your industrial sector. Equipped with functional safety and reliable emergency stops, it ensures industrial environments achieve the best level of safety.

Contactron Hybrid Technology is an important investment to protect all your assets from various serious threats through a smooth soft switching mechanism, minimal sparks and equipped with reliable functional safety.

Portfolio Contactron Hybrid Motor Starter can replace conventional reversing contactors (mechanical) because it has been equipped with protection features in one device, so that 3-phase motors can operate safely, effectively and reliably.

PT. Bawalaksana Central Industrial as Authorized System Integrator and Solution Partner of Phoenix Contact can provide complete support for your company in the implementation of Contactron Hybrid Technology devices.

We have extensive access to all the technologies offered by Phoenix Contact. That way, the integration of sophisticated systems in your company can be done seamlessly without a hitch.

If you are interested in implementing smart contactors with Hybrid Technology, please connect with our professional team.

Click the contact us button below to start a discussion with our Application Engineer team today.

Piko Prasetyo

Application Engineer

This article was written in collaboration with Piko Prasetyo, an expert in Automation, Embedded Systems and Artificial Intelligence, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)

![Problems with 3 Phase Contactors and How to Solve Them [Practical & Effective]](https://bawalaksana.co/wp-content/uploads/2025/07/Masalah-Pada-Kontaktor-Motor-3-Phase-dan-Cara-Mengatasinya-Bawalaksana-ID-1080x675.jpg)