To make the production process more effective, manufacturers can use a number of systems and methods such as the following:

- Quality Management

- Warehouse Management

- Supply Chain Management

- Lean Manufacturing

- Manufacturing Execution

- Six Sigma

- Automation System

What is Lean Manufacturing?

Lean manufacturing is a systematic approach to production and process management. The focus of this system is to optimize value (product/company) while minimizing “waste” (something that has no value).

What is Automation and Robotics?

Automation and Robotics is a system that combines technology and machines to carry out various tasks that are usually performed by humans. The purpose of implementing this system is to increase the level of productivity and efficiency of manufacturing, especially in the Industry 4.0 era.

In the manufacturing world, efficiency and effectiveness are key to maintaining competitiveness in the global market. Companies need to use various systems and methodologies to optimize their production processes, including the 7 systems we mentioned above.

In this article, the Bawalaksana team will discuss these 7 vital systems so that the production process becomes more effective, as follows:

Quality Management Systems (QMS)

A Quality Management System (QMS) is a formally documented system that records the processes, procedures and responsibilities for achieving a company’s policy and quality.

By implementing QMS in manufacturing, it will provide many benefits, including:

- Coordinate and direct the activities of the organization in meeting customer and regulatory requirements.

- Continuously improve manufacturing effectiveness and efficiency.

In Indonesian, QMS is also known as Quality Management System (QMS). This system allows companies to manage the quality of products or services sold to customers.

In practice, QMS implementation often refers to International Standards such as ISO 9001:2015.

This International Standard will provide a framework for an effective and sustainable quality management system.

Details of Benefits in Quality Management Systems

Quoting from ASQ, that implementing Quality Management Systems (QMS) can affect every aspect of performance in the organization, with details of the benefits as follows:

- Meeting customer requirements: This can help to instill confidence in the organization. This in turn can contribute to more customers, more sales and more business cycles.

- Meet organizational requirements: As a form of regulatory compliance to provide products and services in the most efficient manner. This is in terms of cost and resources, and creates room for expansion, growth and profitability.

Apart from the two benefits of the QMS system that we have mentioned above, there are still other benefits that can be obtained, such as:

- Reducing waste

- Prevent errors

- Save costs or cost

- Sets the direction of the entire organization

- Facilitate and identify training opportunities

- Contribution of company staff to sustainability

- Define, improve and control processes

- Communicates readiness to deliver consistent results

Lean Manufacturing

According to Wikipedia Lean Manufacturing is a production methodology that focuses on reducing the time spent in the production system as well as the response time, from the supplier to the customer.

This method is closely related to the concept of Just-In-Time (JIT) Manufacturing, which aims to adjust production based on actual demand (market).

The means is to only produce the goods that have been ordered.

As a result, JIT manufacturing can significantly improve production efficiency.

Likewise, productivity is continuously improved by increasing production and supply chain effectiveness.

When referring to Process, the main goal of Lean Manufacturing is to increase efficiency, save costs, improve product quality and ultimately provide greater value to customers.

Key Principles in Lean Manufacturing

As we quote from Process, the core of Lean Manufacturing is built on the principles of identifying and eliminating waste.

The “waste” referred to here refers to any activity or resource that does not contribute to the creation of value for customers.

The key principles in Lean Manufacturing are as follows:

- Value Identification: Determining what the customer truly considers valuable.

- Value Stream: Identifying and eliminating waste in each process.

- Process Flow: Ensure that the process can run smoothly without a hitch.

- Pull: Produce what the market needs, rather than what is forecast.

- Perfection: Continuous improvement.

Benefits of Lean Manufacturing

According to ToughNickel the implementation of Lean Manufacturing in manufacturing can bring various benefits, among others:

- Waste Reduction: Helps companies to identify and reduce waste in production, including waiting time, overproduction, overprocessing and others.

- Quality Improvement: By focusing on efficient production processes. So that errors and production defects can be minimized. That way the quality of the product or service can improve.

- Cost Efficiency: Reduce wastage which can directly impact the reduction of production costs.

- Faster Production Times: Eliminates waste in the production process which can lead to shorter production times.

- Customer Satisfaction: By paying attention to the value expected by customers and improving the quality of products offered, customer satisfaction can be improved.

- Flexibility: Lean Manufacturing can improve manufacturing’s ability to adapt to changing market demands more quickly and effectively.

- Improved Employee Morale: The system also adopts an approach that involves employees in a continuous improvement process. So it can then help to increase the engagement of all employees and boost their morale.

For your information, the philosophy of Lean Manufacturing was first introduced by the Toyota Production System (TPS) which was developed in the 1950s.

This was later adopted and adapted by various industries around the world.

Six Sigma

According to Wikipedia, Six Sigma (6σ) is a quality management methodology that aims to reduce variation in production and business processes, thereby reducing production defects and increasing customer satisfaction.

Six Sigma was first introduced by American engineer Bill Smith while working at Motorola in 1986.

This system can be implemented using empirical and statistical quality management methods. In its implementation, it is necessary to involve people who act as Six Sigma experts.

If your company wants to implement this method, then there will be certain targets that must be met. So that companies or manufacturers can meet Six Sigma criteria with a predetermined minimum level limit.

Six Sigma Objectives and How to Calculate Them

The goal of Six Sigma is to achieve virtually no defects or failures in processes (either services or products).

It is measured by a predetermined Sigma Value and is defined as no more than 3.4 defects per million opportunities (Defects Per Million Opportunities).

This means that the process must be able to operate at a very high level of efficiency, reaching 99.99966% efficiency.

It is worth mentioning that the value of 3.4 is the value defined as the lowest Sigma level.

The efficiency percent (99.99966%) is considered as the Mean value.

When the Sigma level of a manufacturer or service provider is more than 3.4, the company can be said to have a poor level of production defects.

Please note, that to calculate the Sigma level, a team of experts in the field of statistics is required.

That way, your company can know the exact and accurate figures based on the total production defects, errors and/or defect rates calculated in percent (%).

Six Sigma Methodology

In its application, Six Sigma has two main methodologies:

- DMAIC (Define, Measure, Analyze, Improve, Control)

This method is generally used to improve existing processes.

DMAIC is a systematic approach that can help organizations identify and solve the problems they are facing.

By doing so, manufacturers can improve production quality and efficiency.

It should be noted that for the implementation of the DMAIC methodology to work well, commitment from all levels of the organization is required. As well as a strong understanding of the principles of quality management.

- DMADV (Define, Measure, Analyze, Design, Verify)

This second method has a different function than the previous one. DMADV is an effective method for new product or process development in manufacturing.

The aim is to ensure that the new initiatives designed keep quality and customer satisfaction in mind from the initial phase.

Through a structured and data-driven approach, manufacturers can increase the success ratio of new products or processes they adopt.

Benefits of Six Sigma for Manufacturing Companies

The benefits of Six Sigma implementation in manufacturing companies are certainly numerous. Both in terms of improving product quality, cost-efficiency, customer satisfaction and increasing revenue.

The following are 6 benefits of implementing Six Sigma for manufacturing that we summarize from various sources:

- Product Quality Improvement

Six Sigma uses a data-driven approach and statistical methods to identify and eliminate defects or errors in a production process.

One way to do this is by reducing product variations, so that the quality becomes better and more consistent.

AQS mentions that Six Sigma can be implemented as a business strategy through projects that are selected based on their impact on the organization’s end results.

To achieve this, of course, it is necessary to get support from top-level management to involve all employees.

- Process Efficiency

The application of Six Sigma methods can help reduce variation and improve process control, which in turn can improve efficiency.

The Corporate Finance Institute says that Six Sigma can be applied to any process in any industry to build a management system to identify errors and eliminate them.

This can contribute to improving the efficiency of business structures, process quality and profitability of a business.

- Cost Reduction

Six Sigma can help companies reduce production costs by reducing defects and improving efficiency.

According to BrandMinds, using the Six Sigma method, Motorola managed to reduce product defects to 1/100 in four years.

This had a positive impact on the company and led to Motorola winning the Malcolm Baldrige National Quality Award in 1988.

- Customer Satisfaction

As we mentioned earlier, Six Sigma methods can also contribute to increasing customer satisfaction and even revenue of a company.

Six Sigma Daily reveals the secret of how Amazon founder Jeff Bezos was able to increase the company’s revenue by 37% or $386 billion in a year.

Jeff Bezos’ Working Backwards approach is a reflection of the Six Sigma method, which focuses on understanding customers’ needs and fulfilling them.

As a result, the company’s growth and revenue increase as more customers become satisfied.

In fact, Amazon can maintain customer loyalty and increase market share in the marketplace industry.

- Increased Profits

Implementing Six Sigma in a manufacturing company can increase efficiency levels and minimize production defects.

That way, an increase in profits achieved by the company is a necessity.

The Six Sigma method can help in measuring, analyzing and improving the process. So that the company can improve operational efficiency and increase productivity.

When processes become more efficient, the product or service can be delivered at a lower cost and in less time.

As a result, all of these things can in turn increase the profitability of the company.

- Better Company Culture

The sixth benefit of implementing the Six Sigma method is to help manufacturers build a good culture.

The ways that can be done based on the references we obtained from iSixSigma are as follows:

- Change the way of working with a focus on process: Six Sigma combines education with hands-on problem solving. So the way of working is oriented more towards effective processes and customer satisfaction, rather than departments, functions or tasks.

- Spreading knowledge and improvisation: Six Sigma does not only rely on specialists to make improvements, but also involves project leaders, team members and managers who get Six Sigma training and certification.

- Developing leaders for Six Sigma: Six Sigma methods can be an opportunity to develop leadership competencies. These are positive influence, persuasion, systematic approach, effective communication, handling ambiguity, vision and conflict management.

- Utilize dashboards to make better decisions: It is common that managers tend to flip-flop between strategy and action. The benefit of the dashboard itself is as a tool to determine execution and strategy. Thus, it will make managers more careful and balanced in taking an action.

The following table provides a global overview of the differences between traditional manufacturing cultures and those that have implemented Six Sigma.

| Aspects of Culture | Traditional | Six Sigma |

| Work orientation | As per department, function and/or task | Process flow and everything related to customer satisfaction. |

| Who can determine what needs to be improved | Senior managers and department managers | Seniors and managers from each department, plus suggestions from subordinates ranging from project leaders and team members. |

| Leadership for improvement | Functional manager or designated project leader | Champions and improvement specialists (corresponding to Six Sigma belts). |

| Who has the skills to develop and implement the solution | Specialists (e.g. engineers) and managers | Subject matter experts plus project leaders, team members and managers. |

| Repair methods and tools used | The most familiar person | Common and comprehensive approaches and tools. |

| Operator engagement level | Ad hoc | Disseminated through Yellow Belt training. |

| Project management disciplines related to improvement | Variable | Gate reviews at every DMAIC step. |

| How performance is measured | Actual vs. budget | Impact on Xs (causal measure) that affects Ys (outcome). |

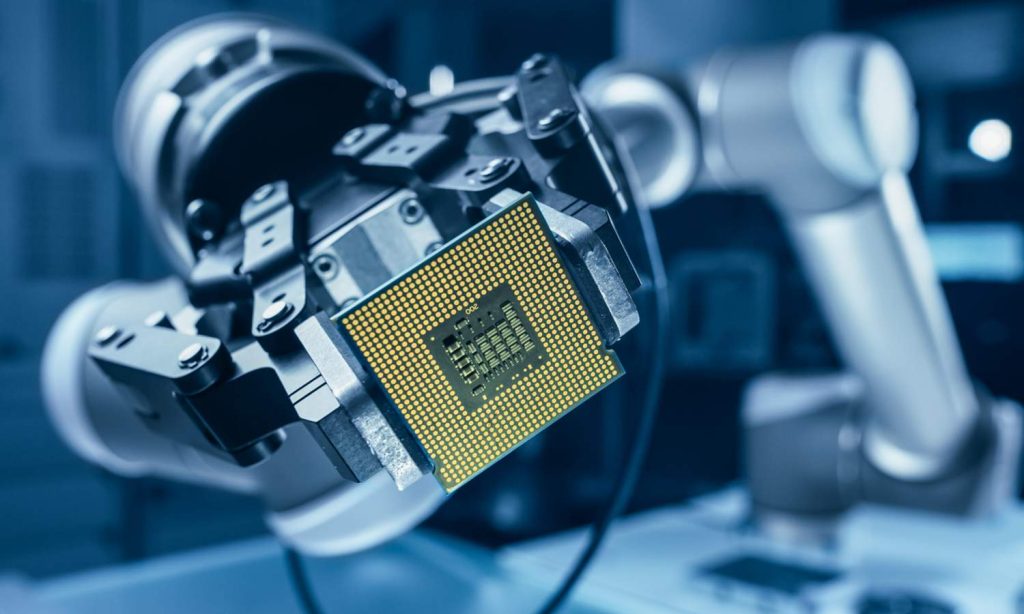

Automation Systems and Robotics

As we mentioned earlier, industrial automation and robotics are systems that combine technology and machines. This system aims to carry out various tasks that are generally performed by humans.

Automation systems can be designed for various industries and commercial manufacturing. The implementation of this system can provide benefits in terms of improving quality, accuracy and speed of production.

The implementation of automation and robotics systems in manufacturing can be combined with any of the three systems we mentioned earlier. That way, manufacturing companies have advantages that can outperform their competitors.

When talking about automation systems, of course, it is also closely related to robotics systems.

What are the benefits of automation systems and robotics for manufacturing?

Before discussing the benefits of a robotics system or Robotic System, it is necessary to know the definition first.

Robotic System is a branch of technology that deals with the design, construction, operation and use of robots.

A vendor can design a robot designed to carry out tasks that may be difficult or dangerous for humans.

Quoting from Robotiq, that currently the use of robots is common. The main role is to carry out heavy and dangerous tasks.

As is well known, there are some very dangerous jobs in manufacturing. Therefore, involving robots is the best way to go.

A robot can be designed with the specific purpose of lifting very heavy objects or stirring 2000°C molten metal.

As technology develops, robot manufacturing will incorporate various disciplines such as mechanics, electronics, computers and Artificial Intelligence (AI).

That way, automation systems in industry can operate automatically or semi-automatically by involving robots.

As a result, production processes in manufacturing are faster, safer for workers, cost-effective, and produce more consistent, high-quality results.

Example of Automation and Robotics System Implementation

The following are some examples of the application of automation systems and robotics in various industries or manufacturing.

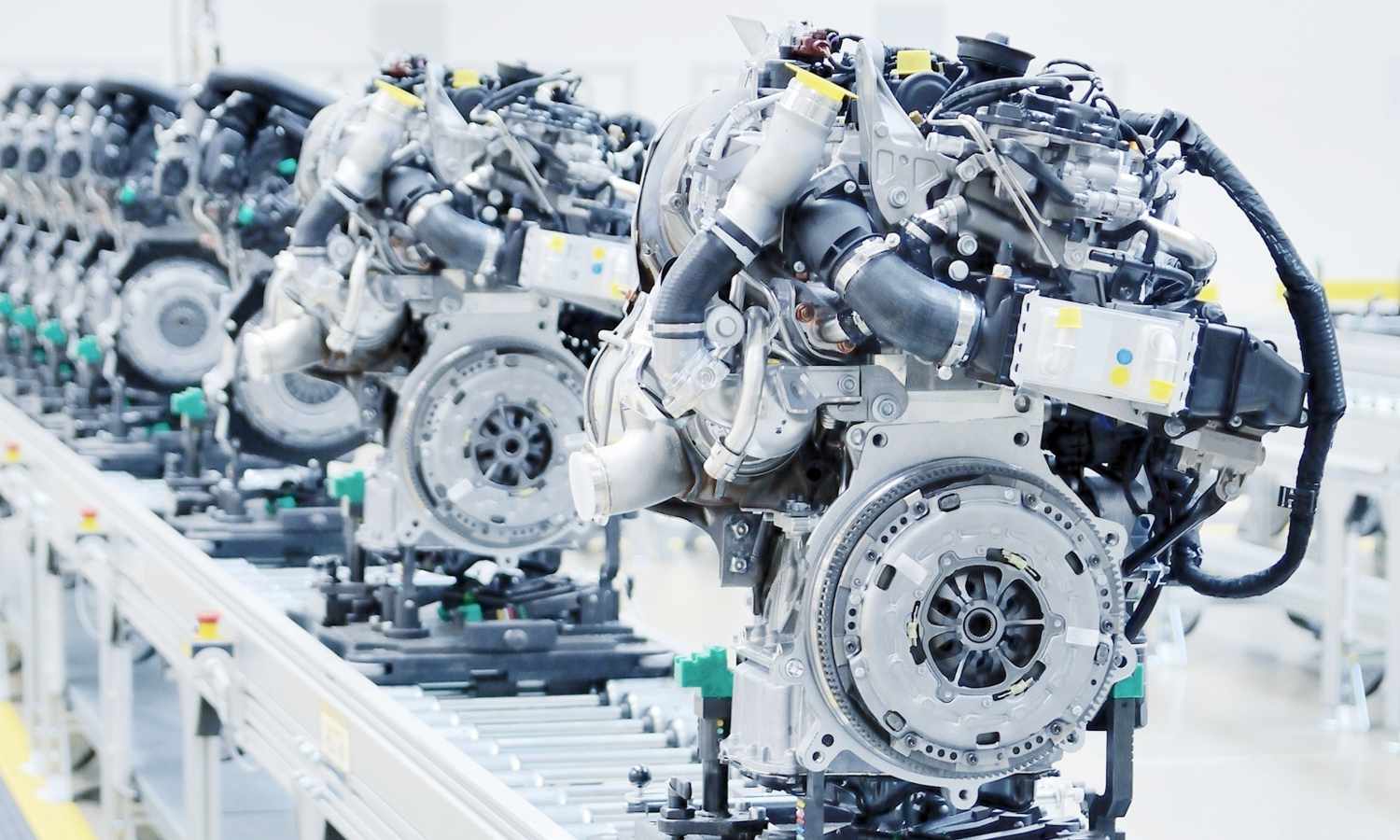

- Manufacturing: An arm robot used for the assembly of electronic or automotive components.

- Agriculture: An automated irrigation system that regulates crop watering based on programmed water requirements.

- Healthcare: A surgical robot that helps doctors perform surgeries with high precision and speed.

Benefits that can be achieved by using automation systems and robotics

- Time and Cost Efficiency: Reduce processing time and operational costs.

- Reduction of Occupational Risk: Reducing the risk of injury to workers in hazardous work environments or to objects being worked on.

- Quality and Accuracy: Improve product quality and accuracy in production or service.

Important Components in Automation and Robotics Systems

For automation and robotics systems to work properly, a number of vital components are required, such as the following:

- Sensor

- Actuators

- Controller

- Software

- Pneumatic device

- Frame or chassis

The robot’s prime movers are electric, pneumatic or a combination of both (electro-pneumatic) actuators.

In other words, actuators and pneumatic systems are the prime movers of a robot or robot arm.

Therefore, these two components require regular maintenance and periodic inspection. So that it can support the performance of the industrial automation process to be more effective and productive.

On the contrary, when these two components are not well taken care of, it will affect the accuracy level and high energy consumption. It can even result in downtime which results in increased production costs.

The Vital Role of Pneumatic Hoses in Automation Systems

Pneumatic Hoses Pneumatic hoses are components used to deliver pressurized air to all parts of the automation system.

Pneumatic hoses are likened to veins or muscles in humans that can channel energy (in this case pressurized air) to actuators to produce mechanical movement.

That way, the moving devices on the robot can function accurately, automatically or semi-automatically.

Pneumatic hoses are the best choice for automation systems and robotics, as they have been recognized for their flexibility and strength.

The existence of pneumatic hoses enables smooth and precise movement in robotics applications.

Use of Pneumatic Hose in Industrial Automation System

Pneumatic hose is an important part of the Pneumatic System in industry to run automation systems.

The following are some examples of the implementation of pneumatic hose hoses in various industries or manufacturing as we quote from The Engineer Post:

- Industrial robots

- Automotive industry

- Manufacturing industries

- Machine tool manufacturers

- Processing industries (petrochemical, food processing, textiles, paper)

As for some of the tasks that can be done by pneumatic system in the industrial world are as follows

- Filling and mixing ingredients

- Product packaging

- Assembly system

- Clamping

- Drilling

- And more

As additional information, the use of pneumatic hoses can be very broad and is not limited to industry or manufacturing.

For more information on pneumatic hose implementation, please visit our article, 15+ Industries that Use Pneumatic Systems.

Manufacturing Execution Systems (MES)

Quoting from Wikipedia, Manufacturing Execution Systems (MES) is a computerized system used in manufacturing to track and document the transformation of raw materials into finished goods.

MES provides information that will help in making decisions, as well as to understand what the current conditions are on the plant floor. This can further contribute to the optimization of production output.

Indirectly it can be said that the MES serves as a real-time monitoring system for regulating a number of production processes.

What are the Benefits of Manufacturing Execution Systems?

There is no doubt that today’s manufacturers are under enormous pressure to develop high-quality products quickly and cost-effectively.

This is what Industry Week wrote when talking about the benefits of Manufacturing Execution Systems which include the following:

- Reduce scrap and waste

MES can help manufacturers to deal with production scrap or waste that comes from broken parts and wasted materials.

- Capture costs more precisely

By using MES, manufacturers can determine production costs more accurately and in real-time. This can include labor costs, waste, downtime, tooling costs and other costs that occur directly on the factory floor.

All of this information is crucial for manufacturers, as it can be used to price new products and renegotiate unprofitable business.

In short, MES can help companies make better business decisions based on accurate and timely production cost data.

- Increase uptime

Uptime is a key factor in manufacturing productivity. The higher the uptime, the more products that can be produced so that it can contribute to a significant increase in revenue.

By using MES, the company can find out the schedule and preventive maintenance that is well integrated.

- Reduce inventory

Using MES can help in inventory management with up to date information, including the following:

- New production

- Leftover products

- Unsuitable materials

- And others

Thus, the people responsible for purchasing, shipping and scheduling will know what materials are still available or have not been optimized.

This will also help the company to avoid excessive and unnecessary inventory.

For your information, reducing inventory has many benefits, including:

- Increase Company Profits: This is because manufacturers can save on raw material purchasing, storage and management costs. In addition, the company can also improve its cash flow effectively.

- Maintain Product Quality: By reducing inventory, companies can reduce the risk of damaged, expired or obsolete products. A fresher and better quality product will increase customer satisfaction and loyalty.

Supply Chain Management

Supply Chain Management (SCM) is the management of the flow of goods and services involving the movement and storage of raw materials, inventory and finished products from the point of origin to the point of consumption.

In Indonesian, SCM is also known as Supply Chain Management which involves coordination and collaboration between channel partners, including:

- Supplier

- Intermediary

- Logistics service provider

- Customer

The goal of Supply Chain Management is to minimize costs and operational efficiency and to increase customer satisfaction.

Benefits of Supply Chain Management

Supply Chain Management has a variety of significant benefits for manufacturing companies, including:

Operational Efficiency

With good Supply Chain Management in place, companies can improve their operational efficiency, reduce production costs and avoid unnecessary excess stock.

Product Quality Improvement

With tight control over the supply chain, manufacturers can ensure the quality of raw materials used in the production process. That way the products produced will be of higher quality.

Flexibility and Responsiveness

Good Supply Chain Management allows companies to be more responsive to changes in market demand. Moreover, manufacturers can also have the ability to customize production processes quickly and well.

Reducing Risks

A good understanding and practice of Supply Chain Management can help manufacturers to identify and mitigate risks associated with supply disruptions, changes in raw material prices or regulatory changes.

Improving competitiveness

Effective supply chain management can increase competitiveness for manufacturers. This will also make the company able to make products at competitive prices and also good service to customers.

How is a Supply Chain Efficient?

A supply chain is said to be efficient when it is able to optimize the flow of goods or services from suppliers to consumers.

In other words, supply chain efficiency can be seen from how much cost and time can be saved by manufacturing without sacrificing the quality of the products made.

It should be noted that efficiency in the supply chain cannot be achieved easily unless there is good integration between all parties involved.

This includes suppliers or manufacturers, suppliers, distributors and retailers.

Therefore, to improve supply chain effectiveness, sophisticated information technology or software is required.

So that it can help in data transparency and smooth communication.

Is Supply Chain Management Essential for Manufacturing?

In the context of manufacturing, Supply Chain Management has a very crucial and important role in the following ways:

- Save cost

- Optimizing production

- Improve responsiveness to market demand

With effective Supply Chain Management, manufacturing companies can achieve greater efficiency, higher customer satisfaction and good competitiveness in an increasingly competitive market.

Warehouse Management System

Warehouse Management Systems (WMS) are software solutions designed to support and optimize warehouse management and distribution operations.

In Indonesian, WMS is also known as Warehouse Management System that provides tools to manage inventory, work orders, warehouse equipment and order fulfillment processes effectively and efficiently.

Key benefits of a Warehouse Management System

The following are some of the benefits of implementing a Warehouse Management System (WMS):

- Inventory Optimization: A WMS can help you in accurate tracking of inventory, as well as to reduce counting errors and prevent overstock or stockouts.

- Improved Operational Efficiency: Through automation of processes, such as placement and picking, a WMS can increase productivity and reduce operation cycle time.

- Order Accuracy: The system can help in improving order delivery accuracy by ensuring the right items are delivered to the right customers.

- Reporting and Analysis: WMS also provides detailed reports and analysis of warehouse performance. This allows for better decision-making and a pattern of continuous improvement.

What are the Main Objectives of a Warehouse Management System?

The main objective of a Warehouse Management System is to provide an organized and effective process in warehouse operations, which includes the following:

- Manage the receipt and storage of goods.

- Optimize the placement and retrieval of goods.

- Ensure inventory accuracy and order fulfillment.

- Reduce operational costs through efficiency and error reduction.

Warehouse Management Systems (WMS) play a key role in improving the efficiency and accuracy of warehouse operations.

With a variety of benefits and objectives on offer, WMS is becoming an important investment for companies across various industry sectors.

In this article, we have discussed 7 vital systems that can make the manufacturing process effective.

By integrating all these systems, it is hoped that manufacturing companies can improve product quality, operational efficiency, customer satisfaction and competitive advantages.

Today, many manufacturers have implemented some of the seven systems we have mentioned, particularly industrial automation systems.

Industrial automation systems are commonly implemented by manufacturers in various sectors. Because it can contribute to productivity, cost-efficiency and sustainability.

PT. Bawalaksana Central Industrial is one of the companies engaged in the Industrial Parts Supplier. We can supply a variety of quality products to meet the MRO (Maintenance, Repair, Operation) needs of your company.

Among the devices that we can supply are pneumatic automation parts and components such as actuators, FRL units, valves, to pressure gauges, mechanical and electrical parts and various supporting devices for industrial automation systems.

For more information about our products and services, please visit our Sales Enginer team by clicking the contact us button below.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)