Manufacturing in the modern era faces many major challenges that can threaten business resilience, such as:

- Global energy market disruptions caused by geopolitical issues

- Constantly changing demand and trend towards batch size one (individualized production demand)

- Potential unplanned downtime resulting in losses of up to $50 million or Rp. 814 billion, as reported by the Wall Street Journal

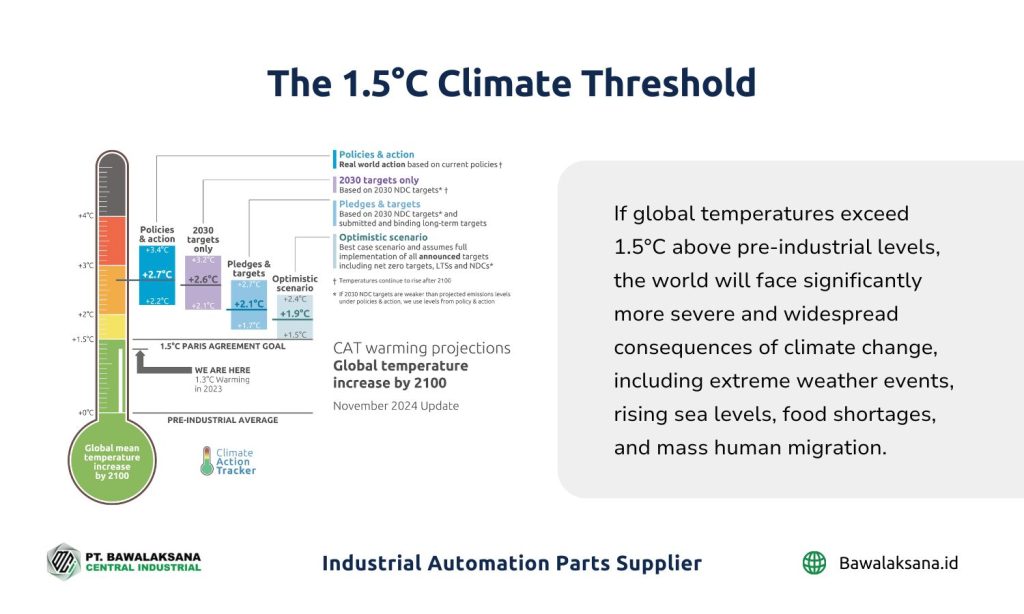

At the same time, the industrial sector is required to meet the 1.5°C target as in the international agreement in the Paris Agreement. This agreement is a joint commitment to avoid the adverse effects of climate change and global warming due to massive industrial activities.

Environmental Sustainability and Brand Selection Key Issues

It must be recognized that the industrial sector contributes greatly to climate change and the environment. Therefore, the demand to apply the concept of sustainability to the environment is increasingly echoed.

The concept of environmental sustainability has also become a major issue that influences consumer decisions when choosing a brand.

According to a survey by OnePoll, 55% of American consumers would stop using a brand’s products if it was found not to be committed to environmental sustainability.

Meanwhile, a survey from Ipsos Global Trends provided a more surprising report, where 63% of respondents from 25 countries stated that it was more important to them that companies work to fight climate change than pay taxes properly, as quoted from the World Economic Forum.

If the global temperature does not reach the 1.5°C target, the world is in danger!

The Earth is predicted to reach a temperature rise of up to 2.1°C by 2100. By that year, global temperatures will continue to rise uncontrollably if we don’t reach the 1.5°C target starting from now!

If global temperature rise exceeds 1.5°C compared to the pre-industrial era, the world will face much more severe and widespread climate change impacts. Extreme weather, sea level rise, food crisis and massive human migration.

Public Demands, Engineers Welcome

Increasing public awareness of climate and environmental changes due to massive industrial activities has prompted manufacturing experts to innovate to achieve the 1.5°C target, decarbonization and environmental sustainability without compromising economies of scale and production quality.

So there is a push to implement Digital Factory, as the challenges of manufacturing in the modern era increase.

On this precious occasion, the Bawalaksana.id team had the golden opportunity to discuss this interesting topic about Digital Factory. We also want to discuss the link between manufacturing digitalization and the future advancement of industrial automation.

The public’s high awareness of environmental sustainability issues has made the Digital Factory initiative a hot topic of discussion. Followed by the massive development and implementation of IIoT, Artificial Intelligence and Machine Learning in the industrial sector.

Given how crucial the concept of Digital Factory is to the industry, we felt the need to cover this theme in full and in detail.

Please refer to the following exclusive discussion from Bawalaksana.id.

What is a Digital Factory?

A Digital Factory is an ecosystem within an organization that unifies and connects people, industrial processes, machines and technology to create integrated, data-driven manufacturing.

Data is vital in the Digital Factory concept because it is the capital to create quality processes, improve productivity, efficiency, safety and sustainability in the manufacturing environment and the world at large.

The Digital Factory initiative comes from a far-sighted vision and constructive awareness to build an industry that supports climate and environmental sustainability, in an effort to achieve the 1.5°C target and net zero factory by 2050.

We need to inform you that the term Digital Factory has many meanings, which broadly speaking have the same purpose and are interrelated.

The following are some definitions of Digital Factory or Digital Factory that we have summarized from various trusted sources:

Digital Factory as a Place of Change

Quoting from McKinsey in an article entitled Welcome to The Digital Factory, that the Digital Factory is a “construction site” where change occurs. The factory consists of a dedicated cross-functional team working together on a business change program.

They resemble factory workers in that they use reusable tools and repeatable processes to build a specific product in the form of a new experience, service or solution.

Similarly, OpenText™ explains in the article, What is a Digital Factory, that a Digital Factory is an organizational model for creating and maintaining one or more digital products, services or experiences. An organization may establish a number of digital factories where each digital factory consists of cross-functional teams working vertically and fully addressing elements of the digital product creation lifecycle, from business opportunity analysis and user experience development to backlog management, application development, testing, deployment and ongoing operations.

In short, the description given by McKinsey and OpenText™ is more specific to industries that can create solutions for consumers in digital form.

An Ecosystem that Provides All Digitally Connected Information Flows

Quoting a white paper from Brainport Industries titled Digital Factory of the Future, the Digital Factory is an ecosystem where all information flows are digitally connected, seamless and secure, both internally and throughout the chain.

This transformation aims to create data-driven economic value. This is because the manufacturing industry generates a lot of data that potentially represents great economic value.

Through this project, the company can improve operational performance, develop new services and address public challenges. That is, by converting the data into complete factors of production.

This explanation from Brainport Industries is more about digital transformation for the industrial and manufacturing sectors. By connecting all information flows digitally to gain useful insights and increase data-based economic value.

Virtual Model that Represents the Main Shape of the Factory

In an article entitled, The Digital Factory and Connected Data are the Future of Manufacturing published by Autodesk , it is explained that the Digital Factory is a shared virtual model that represents the main characteristics of a factory (such as its geometry, behavior and performance) that features the convergence of all digital networks within the facility and its operations.

This digital representation combines (read: connects) data from existing structures, systems, assets and processes. This gives company owners insight into how to design, build and manage facilities, as well as how to reconfigure them, and how to maximize the efficiency and productivity of each asset.

This ecosystem is open (free) from organizational silos, enabling real-time collaboration, smarter decision-making and better outcomes.

If you notice, this description from Autodesk is more detailed than some of the definitions we mentioned earlier. Where the Digital Factory has a digital twin that can represent the factory as a whole.

That way, company owners can manage, collaborate with all their departments and adjust their operations effectively based on the challenges they face.

Dynamic Network that Organizes Production Facilities

According to German Edge in a publication titled, Digital factory: Definition, Advantages, Implementation, explains that a Digital Factory is a dynamic network of various digital models, methods and tools used to plan and operate production facilities.

The Digital Factory is more than just real-time recording and evaluation of production data, it also involves business processes, planning and management of the complete production flow.

The Digital Twin as part of it can connect the production floor to the upper floor. That includes production lines, supply chains, factory operations and virtual planning. This plant operates based on data and is constantly changing according to new requirements and technologies.

More than Just a Digital Twin or Smart Factory

Still according to the same source, the Digital Factory is more than just a Digital Twin and Smart Factory.

A digital twin is a virtual reflection of the factory itself, with the same characteristics and operational path.

However, the real (physical) production process and its digital twin can interact intensively with each other. This is very useful for process evaluation or planning in creating new plant/product concepts based on data.

However, the digital twin remains limited to the factory itself and does not include data from the entire business environment or supply chain.

The perfect Digital Twin concept can result in a true Smart Factory with machines that can manage their own processes. That is by using technology based on cyber-physical systems and intelligent networking that connects machines and production processes through the Internet of Things (IoT).

Integration between Operational Technology (OT) and Information Technology (IT)

According to Cognizant in its glossary, the Digital Factory is a production facility where people, machines, raw materials and products have interconnected information related to all stages in the production process instantly.

This integration is supported by smart sensors, accessible cloud storage and Big Data analytics. It combines data and intelligence from previously isolated (silo-based and unconnected) Operational Technology (OT) and Information Technology (IT) systems.

Visual Depiction of Manufacturing to Accelerate Product Innovation and Development Processes

In the Journal of Technology Management from Media Neliti entitled Digital Factory Implementation in the Medium-Scale Manufacturing Industry, it is explained that the digital factory is a visual representation of the manufacturing process and system as a whole, which is used to simulate design, planning and evaluation, both in terms of developing existing processes and systems as well as new processes and systems.

Digital Factory can be used to experiment on work system design with various alternatives easily, without disturbing the current system and work process (Kurkin and Bures, 2011).[1].

Meanwhile, the main function of the Digital Factory is to model, simulate and visualize data, information and environmental conditions as close as possible to actual conditions.

Digital factory helps in accelerating the innovation process, especially in the production system and product development process.

This concept has successfully improved time and cost efficiency in various industries, especially in the automotive, heavy equipment, aviation, shipping, electronics, and daily consumer goods (FMCG) industries.

These are some of the meanings of Digital Factory or Digital Factory that we have summarized from various sources. All the definitions of Digital Factory above are complementary to one another.

At its core, the Digital Factory is the integration of digital technologies into manufacturing operations by creating a smart ecosystem, where data is collected from various sensors and inputs, then used intelligently to derive scalable economic value.

To give you a thorough understanding of the Digital Factory and how it is interpreted in the real world, let’s take a look at the rest of the explanation below.

The Future of Industrial Automation in the Digital Factory Ecosystem

The Digital Factory ecosystem is in a data vortex with full transparency and unrestricts data access based on silos.

As we mentioned earlier, the Digital Factory is built on the concept of a dynamic, data-driven network that is interconnected between people, industrial processes, machines and technology.

This also includes production lines, supply chains and virtual planning to accelerate the innovation process in the production system and product development process.

However, 91% of the 200 companies in Germany that have invested in the Digital Factory, only 6% have achieved full connectivity.

This is the data mentioned by PricewaterhouseCoopers (PwC) in a publication titled, Digital Factory 2020 Shaping the Future of Manufacturing.

Even though there are many benefits that can be obtained by companies with this digital transformation such as:

- Time to market becomes faster

- Manufacturing has better agility to respond to the market

- Can achieve wider customization to meet continuously dynamic demand

- Improving operational efficiency

- Enhance global competitiveness, business sustainability and resilience

Therefore, data acquisition and data processing are of paramount importance, if your company plans to make a digital transformation towards smart manufacturing.

The following is an overview of the future of industrial automation in a Digital Factory ecosystem that operates based on data.

Some of the implementation examples below will give you an overview of what Digital Factory can do for your industry in the future.

Audi Car Production Facility Achieves Carbon Neutral Production

In 2020, German car major Audi announced its Mission:Zero program as part of its commitment to achieve complete carbon neutrality across its production and logistics operations.

The program is Audi’s roadmap for reducing the ecological footprint of its vehicles and production processes, with the ultimate target of achieving carbon-neutral production at all production facilities by 2025.

Some of the production facilities that achieved the Net Carbon Neutral Production mission are Audi Brussels in 2018, Audi Hungary in 2020 and Ingolstadt in 2024.

The question is, how can Audi achieve this remarkable target?

The good news is that we will tell you the secret behind the success of Audi’s production facilities, especially in the Ingolstadt region.

Among the important technologies adopted by Audi to achieve this target are the following:

- PLCnext Technology

PLCnext Technology is a core technology in industrial automation systems and an important device for performing data integration in the Digital Factory.

PLCnext Technology provides an open ecosystem with multiple interfaces from sensors to the cloud, enabling continuous and realtime information flow in the production process.

This technology has also been equipped with cybersecurity features according to the international standard IEC 62443-4-2. So as to maintain the integrity of data and automation systems from digital threats, to ensure a high level of security in digital and interconnected production environments.

- EEM-MA 370 Multi-Functional Energy Measuring Device

The Energy Measuring Device (EEM-MA 370) is critical for monitoring energy consumption in Audi’s production facilities in real time. This device provides detailed data transparency regarding energy flow and early notification if there is any indication of system malfunction.

In fact, this device can help to detect the smallest potential deviations from the quality indicated at an early stage. That way improvements can be made immediately to avoid wasting energy and excessive emissions.

The EEM-MA 370 Multi-Functional Energy Measuring Device is therefore a vital technology to help improve the quality, availability and adaptability of production processes. For example, by minimizing idle time (no-load) and reducing the number of rejected car bodies, the plant can avoid energy waste and increased Greenhouse Gas (GHG) emissions associated with inefficient production processes.

- RFC 4072S Safety Controller

The RFC 4072S safety-related controller is the centerpiece of the automation solution in the body shop sector for Audi facilities. This technology can ensure functional safety in vehicle manufacturing. So that the production process does not jeopardize the safety of workers, machines and the quality of the vehicles made.

In addition, the Safety Controller also offers comprehensive diagnostics for all relevant process and communication data. This feature helps in monitoring all production processes and data that is essential for communication between devices, so that any problems can be detected and fixed immediately.

RFC 4072S Safety Controller supports standard programming languages for PLCs such as IEC 61131-3 to C/C++ and C# for complex realtime applications.

These are among the technologies used by Audi’s Ingolstadt facility to achieve the Net Carbon Neutral Production or Net Zero Emission (NZE) target as mentioned in With Open Automation Into The Electrified Future.

Through an open and intelligent automation platform (PLCnext), Audi can reduce the carbon footprint of production, as well as perform energy consumption monitoring, optimization of production processes while maintaining a high level of cybersecurity. Finally, carbon-neutral production was achieved in January 2024.

Zero Net Energy Building Automation Project

In 2015, the California Public Utilities Commission (CPUC) published an ambitious plan for the development of zero net energy buildings.

The plan states that all new residential construction will be Zero Net Energy by 2020. Meanwhile, all new commercial construction and 50% of existing commercial buildings will be Zero Net Energy by 2030.

For information, Zero Net Energy (ZNE) according to the CPUC is a building that is balanced in terms of energy consumed and produced. The energy produced in this case is renewable energy located on site.

This means that buildings are required to produce the same amount of energy as the total energy consumed over a full year or more.

In the wake of the CPUC’s publication, building contractors in California-as well as around the world-are looking for creative ways to implement Nero Net Energy.

Best Example in Digital Factory for Building Automation Sector

California-based EnergyIQ as a World-Class Training Facility is an excellent example of meeting the Zero Net Energy target set by the CPUC.

After implementing the Digital Factory concept in its building, EnergyIQ was able to achieve achievements such as the following points:

- Building reduces electricity use by more than 50%

- Generates 1.25 times more energy than annual consumption

- Able to operate off-grid for several days

- Reduce carbon dioxide (CO₂) emissions by more than 500 metric tons per year

- Reduce energy consumption for lighting, heating and cooling

Furthermore, that EnergyIQ facilities can store excess energy produced, so that they can operate despite grid disruptions or high demand spikes.

If the building loses its main power, the Photovoltaic (PV) system or solar panels act as a UPS for the entire building.

Through this achievement, the EnergyIQ facility has become a role model for other building contractors to achieve Net Zero Energy standards. They were able to see first-hand that the center is the best standard for implementing energy efficiency through the Digital Factory concept.

How did the EnergyIQ Facility Successfully Realize the Net Zero Energy Concept?

EnergyIQ facilities take a unique approach to achieving Zero Net Energy through the implementation of Building Automation that can centrally and efficiently control various technical functions within the building.

Building Automation System serves to integrate various systems into one network to be monitored and controlled automatically, such as electrical (energy), mechanical, HVAC, lighting and other systems.

The following is the building automation infrastructure that makes up the EnergyIQ facility:

- Automation and SCADA System Integration

EnergyIQ implemented a comprehensive SCADA (Supervisory Control and Data Acquisition) system to monitor and control all aspects of energy consumption and production at the facility.

The system manages nearly 600 power meters, hundreds of lighting circuits, high-efficiency HVAC systems, central cooling and heating systems, electrochromatic glazing systems, as well as integration with solar panels and batteries.

- Solar Panels and Energy Storage Systems

The facility operates 500 kW of solar panels, four DC/AC inverters, three grid-style battery systems and eight charging stations for vehicles.

With this much capacity, the EnergyIQ facility can produce 1.25 times more energy than it needs for an entire year. Any excess energy produced is stored in grid-style battery systems for use during grid disruptions or high demand.

- Controller for System Integration

The EnergyIQ facility utilizes Phoenix Contact’s ILC 2050 BI Controller which acts as the brain to run automation systems in various infrastructure sectors within the building.

In this case, the facility utilized the Niagara platform for integration and data management from multiple systems and comprehensive reporting. The combination of the niagara platform and the ILC 2050 BI Controller enables Building Automation at this facility to run efficiently and reliably.

This is among the information about the Digital Factory implementation by the EnergyIQ facility to achieve the Net Zero Energy target as mentioned in Building Automation: World-Class Training Facility Achieves Net Zero Energy.

These are two examples of Digital Factory implementation at Audi’s manufacturing in Ingolstadt and EnergyIQ’s facility in California. They are among the many case studies and successful journeys of Digital Factory implementation that can result in optimal energy efficiency, productivity, sustainability and net zero emission to achieve the 1.5°C target by 2050.

We will mention some other case studies in the next article.

| Also Read: Industrial Wireless Communication: Cordless Industrial Automation and Coding With Radioline |

What is the First Step to Building a Digital Factory?

Building a Digital Factory in the modern era is not just a good thing to do, it has become a necessity. At the same time, companies are facing major challenges globally with industry requirements demanding environmental sustainability.

Meanwhile, consumers’ awareness of climate and environmental changes as a result of industrialization is also growing.

Today’s consumers are more likely to choose brands that can have a positive impact on the environment and are less willing to buy products from companies with poor environmental practices.

McKinsey mentioned the results of a survey in 2023, that products with Environmental, Social, and Governance (ESG) claims experienced an average sales growth of 28% in the last 5 (five) years.

This reality has encouraged companies and brands around the world to demonstrate their commitment to the environment, including to achieve the 1.5°C target as stated in the Paris Agreement.

As we have explained in this article, Digital Factory is the best solution to face various challenges in the Industrial sector.

The implementation of the Digital Factory offers efficiency, reliability and sustainability, with clear evidence that the concept can create a Net Carbon Neutral and Zero Net Energy industry.

A Digital Factory that operates based on data offers good business resilience for your company. The digital transformation of the manufacturing sector enhances companies’ ability to adapt quickly to global challenges and extreme fluctuations in demand.

The question is, how to implement the Digital Factory concept for companies that are actively operating and have a system that has been running for several years?

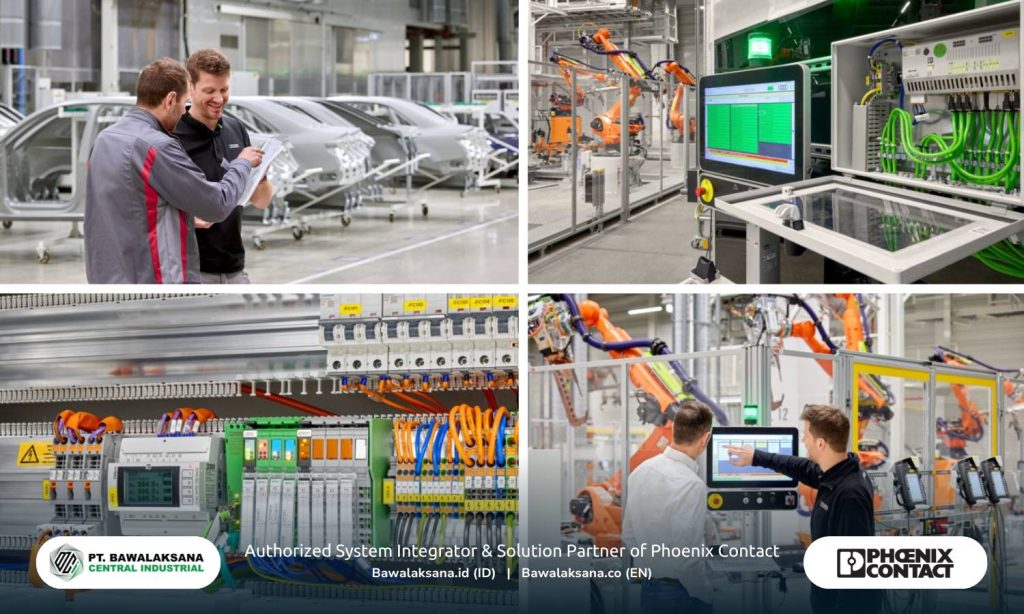

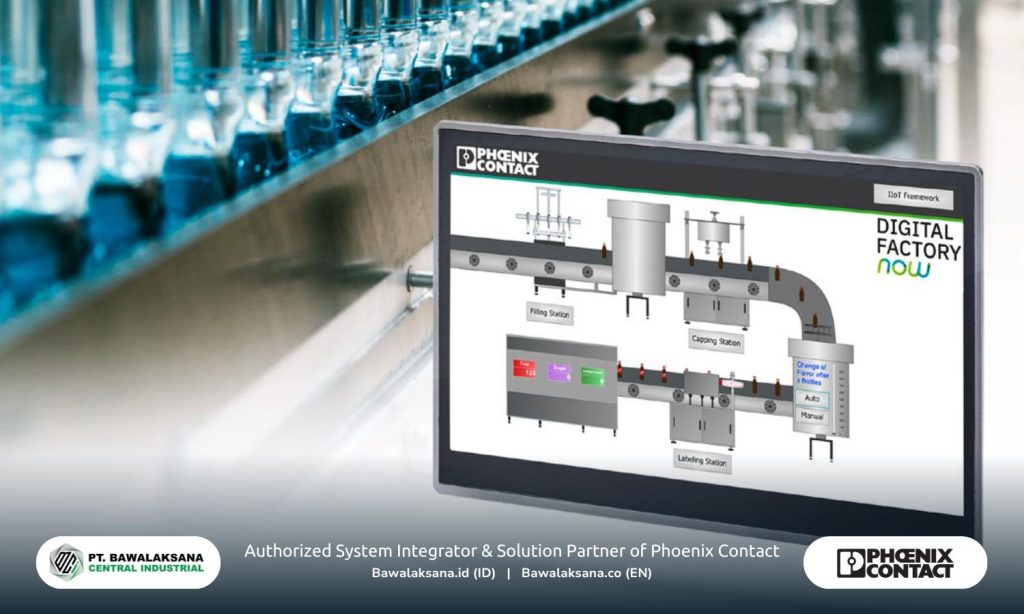

PT. Bawalaksana Central Industrial as Authorized System Integrator of Phoenix Contact can provide a complete and comprehensive solution for digital transformation for your company.

We provide an IIoT Framework that can integrate Operational Technology (OT) and Information Technology (IT) in a practical and scalable way.

The Industrial Internet of Things Framework is a bridging that can seamlessly connect brownfield and greenfield environments without forcing them to make drastic changes.

Regardless of what phase your company is currently in, manufacturing digitalization can be realized easily in stages according to the needs in your industry.

With the right strategy in place for manufacturing digitization, any company or infrastructure can move in this direction without having to invest heavily. That is by gradually updating technology and continuing the process by bringing the right mindset.

Digital transformation is a process and needs to start vertically from the top to the bottom level with a growth mindset and a constructive attitude.

What this means is that we need to have a far-sighted vision, be open to new ideas, positive perspectives and unique innovative solutions.

At its core, the Digital Factory is the integration of digital technology into manufacturing operations by creating a smart ecosystem where data is collected and used intelligently to gain increased economic value.

Data is a vital key in the digital factory to improve productivity, efficiency, safety and sustainability in the manufacturing environment specifically and the world at large.

Therefore, through this grand vision, it is only fitting that we understand the concept of Digital Factory comprehensively and broadly. Departing from the right mindset and data integration that is totality and not just following trends.

All with the aim of improving sustainability, increasing productivity, minimizing security risks and maximizing cybersecurity.

Is your company ready for the big challenges of the modern and smart industrial sector in the future?

Start implementing Digital Factory from now on to increase consumer confidence and realize an environmentally friendly industry.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

REFERENCES:

[1] Kurkin, O. & Bures, M. (2011). Evaluation of operational times by MTM Methods in the Digital Factory Environment. Annals of DAAAM the 22nd International DAAAM Symposium, Vienna, Austria, 2011, 22(1), 671-672.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)