Air Service Unit or FRL Unit is among Main Components in the Pneumatic System which has the following functions:

- Filters the air from dust, dirt and contaminants so that the air becomes clean.

- Removes moisture that can cause rust on pneumatic components.

- Captures oil particles that can contaminate production systems and processes.

- Regulate airflow according to operational specifications in the industry.

- Improve operational safety and security aspects by controlling airflow rates.

FRL Unit is a solution for Air Quality and Treatment so that the air used can meet specifications in various industrial sectors.

Without FRL Unit, the pneumatic system will face various serious problems, such as:

- Dirt contamination

- Decreased performance and efficiency

- Inconsistent work pressure

- Inadequate device lubrication

- Component damage due to moisture and dirt

- Safety threats during air supply disruptions

- Unplanned downtime that causes financial loss

Knowing how crucial air quality is for pneumatic systems, in this article, the Bawalaksana.id team will discuss the function of the air treatment unit (FRL) and how it works.

What is a Filter, Regulator, Lubricator (FRL) Unit?

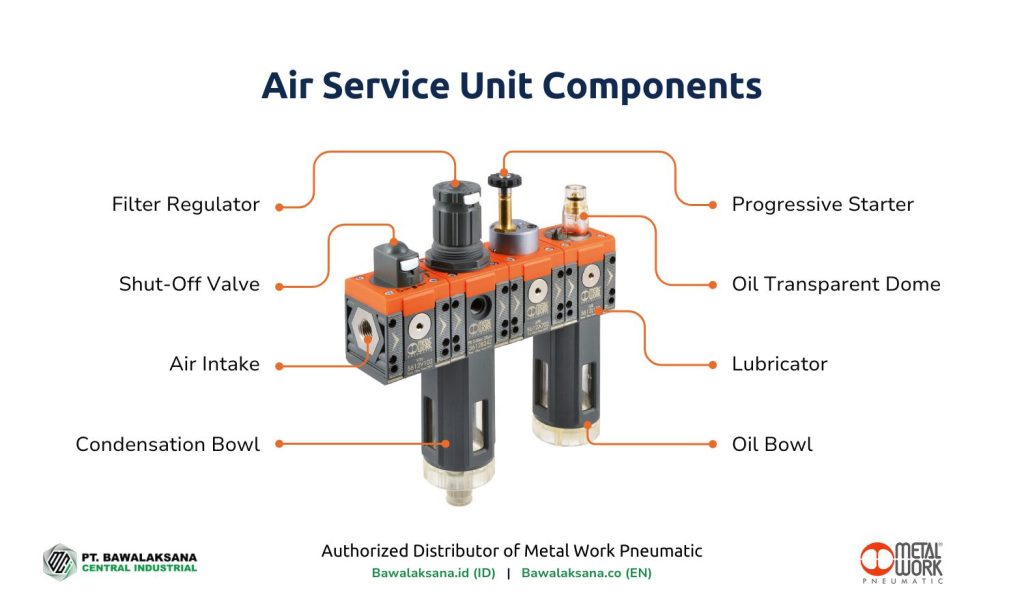

The Air Service Unit device has three main functions, namely filter (F), regulator (R) and lubricator (L), so it is also called the FRL Unit.

Each function of the device is accommodated by separate and modular components, but can be assembled into a single circuit.

However, there are also FRL devices that have integrated (non-modular) functions that include multiple functions and security features, such as the ONE device.

In principle, FRL installation should be done in the correct order, from left to right: Filter → Regulator → Lubricator.

The following are some of the benefits for each component of the FRL Unit:

- Filter: The air will first pass through the filter unit to remove moisture and contaminants.

- Regulator: Next, the air will pass through the regulator unit which functions to regulate the air pressure consistently to be channeled to the pneumatic circuit.

- Lubricator: Air will pass through the lubricator unit which will spray lubrication mist to lubricate the pneumatic components downstream.

These three main functions of the FRL Unit have a great influence on the productivity, durability, efficiency and safety of the pneumatic system as a whole.

Related details, Why Air Service Unit is Vital for Pneumatic System we have explained in the previous article.

In the following, we will outline how the FRL Unit works and some additional components that can enhance its functionality.

How the Air Service Unit (FRL Unit) Works

The Air Service Unit works on the principles of physics in filtration, regulation and lubrication of pneumatic circuits.

In the following we will explain how each unit of the FRL component works, sorted by the first to be entered by air.

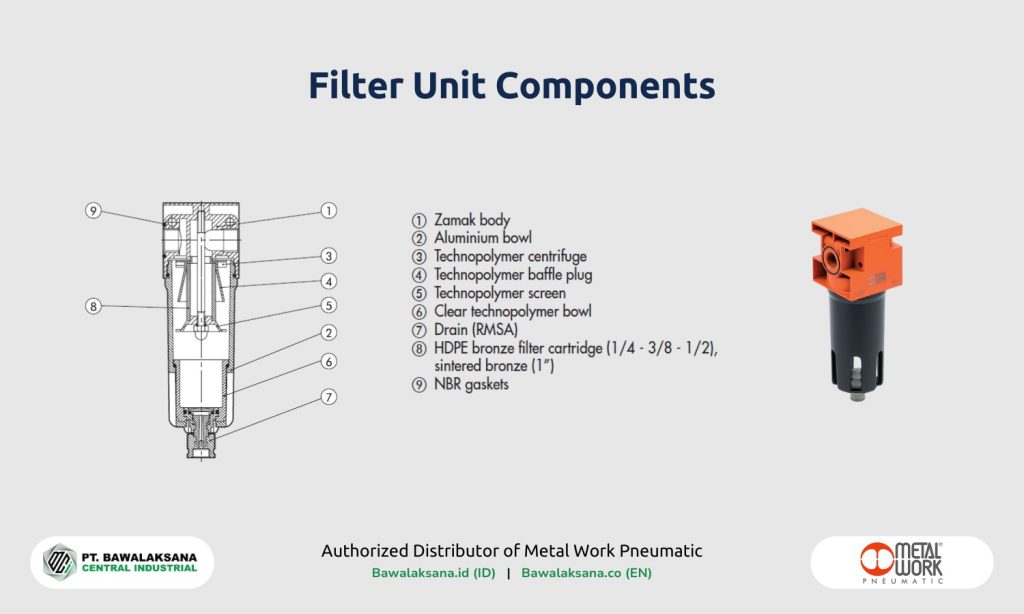

Filtering Air by Utilizing Centrifugal Force

The filter unit is the first component of the FRL that is entered by air. The filtration process occurs when compressed air at high speed enters the unit’s centrifuge, which is a baffle specially designed to create an air loop.

When the air rotates at high speed, it generates centrifugal force. This force causes particles with a higher density than air to be pushed to the edge and stick to the bowl wall.

Solid particles and water are also trapped into the cartridge filter, while air continues to flow away from the filter unit towards the regulator unit.

The accumulated solid particles and water (condensate) will form droplets that eventually settle to the bottom of the bowl due to gravity. This condensate will be retained by the porous filtering element and kept in a calm state to prevent it from re-entering circulation.

The collected condensate can be removed through the drain tap provided.

For your information, the filter unit can filter air particles of 50 μm to 5 μm. In fact, by using the Active Carbon Filter, air can be purified from particles as small as 0.01 μm.

Moisture and water inside a pneumatic system is the main challenge of a pneumatic automation system. It can have a negative impact on the components and overall system performance. If water buildup is left unchecked, it will cause corrosion, mold, performance degradation and even unexpected system failure.(Read: How to Dispose of Water in a Pneumatic System and its Benefits).

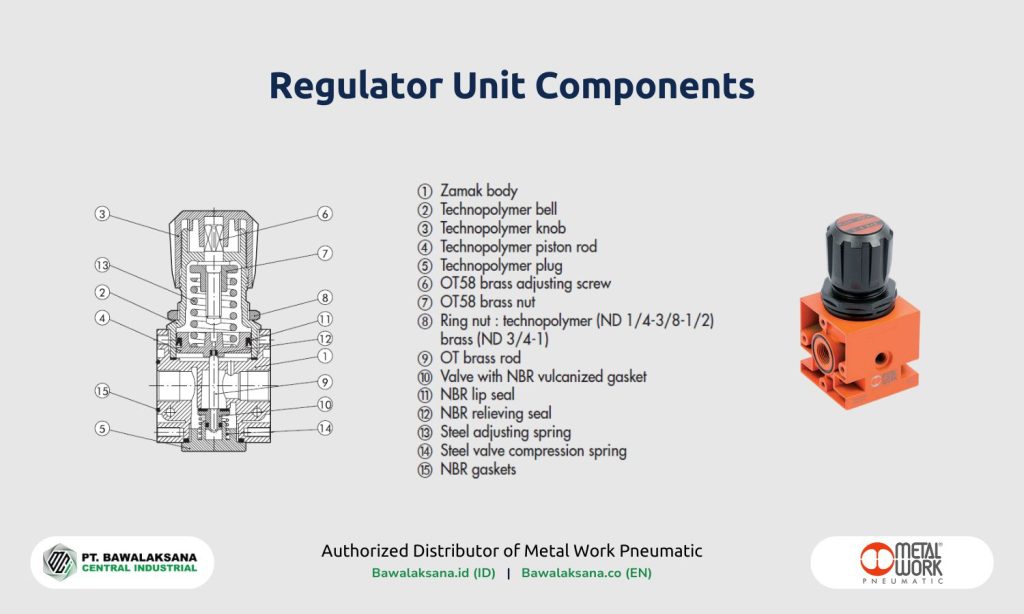

Air Pressure Regulation Through Piston Rod Mechanism

The second unit of the FRL is the regulator, which functions to regulate air pressure according to system needs.

The regulator unit is equipped with many internal components that serve to regulate the quantity of airflow. Among the most essential is the diaphragm, as a component that contributes to creating precise and consistent pressure settings.

Each FRL Unit vendor has a different diaphragm design to control the airflow quantity in the pneumatic line. Among the best types that offer reliable functions are the rolling diaphragm and piston rod mechanisms.

The rolling diaphragm and pistorn rod offer a wider valve opening and have a fast response. This is beneficial for providing greater airflow to the pneumatic circuit as well as more consistent pressure regulation.

The FRL Unit effectively controls airflow and air pressure according to industry standards and system requirements, at pressures ranging from 5-10 BAR (72-145 Psi / 500-1000 Kpa).

The regulator unit can be equipped with a compensation system to maintain a constant pressure, even when the upstream pressure changes.

Features like this can be achieved through the design of pneumatically balanced valves. If the downstream pressure rises above the threshold value, air will be discharged automatically by the Relief until it drops below the maximum value.

From this regulator, the air then flows to the lubricator unit for the lubrication process on the pneumatic channel.

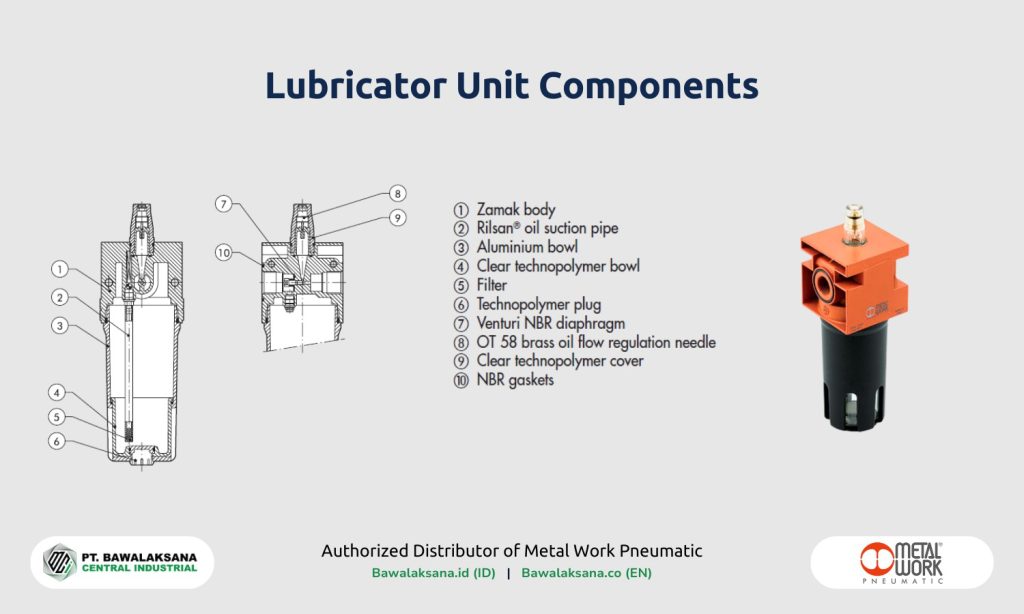

Pneumatic Line Lubrication with Venturi Effect

The lubricator unit is the last part of the FRL Unit device that functions to inject lubricating oil into the pneumatic channel.

This lubrication process uses the Venturi effect, which is a physical principle that states that air passing through a narrowed path will experience an increase in flow velocity, but also a decrease in air pressure.

When pressurized air flows through a narrowed channel (venturi tube), the air pressure drops and creates a low-pressure zone. This event causes the oil in the reservoir (oil bowl) to be drawn through a small pipe into the Flow Regulation Needle (FRN).

The quantity of oil that will enter the pneumatic circuit can be adjusted through the FRN and the droplets can be seen through the transparent oil dome.

As the oil drips into the high-speed air duct, it will automatically break up into small particles or aerosolized mist.

This process takes place continuously, so that the lubricant mist is pushed by pressurized air to the downstream parts of the pneumatic system, such as solenoid valves, pneumatic cylinders and air tools.

This lubrication is useful for minimizing friction between moving metal components, as well as protecting them from wear and corrosion.

This is how the FRL Unit works as a whole, starting from the filter, regulator and lubricator.

Through these three FRL components, the pneumatic system can work optimally and the components have a long service life.

Please note, that in industrial applications with high standards, FRL Units cannot stand alone. There are additional components and technologies that need to be integrated to enhance its functionality.

By adding the right technology to the FRL Unit, the pneumatic system in your company can achieve optimal productivity and efficiency levels.

Next we will mention some additional technologies and components for FRL Units and their benefits for pneumatic systems.

Additional Air Service Unit Components to Enhance FRL Unit Functionality

Pneumatic systems have become a popular and economical choice for automation systems that require mechanical movement. To ensure optimal performance and meet high standards, FRL Units need to be equipped with several additional components and features.

So that this air preparation unit can achieve better functions from the aspect of air treatment and control. Among these additional components are carbon filters, coal coalescence cartridges, shut-off valves, soft start valves and others.

Active Carbon Filter

It is an activated carbon filtration system that can achieve the highest purification standards. This component can remove all traces of oil, solvents and hydrocarbons, and can eliminate bad odors found in the air.

The principle of operation is to use an activated carbon filter, which absorbs most of the polluting particles in the air by the presence of small holes in the carbon granules.

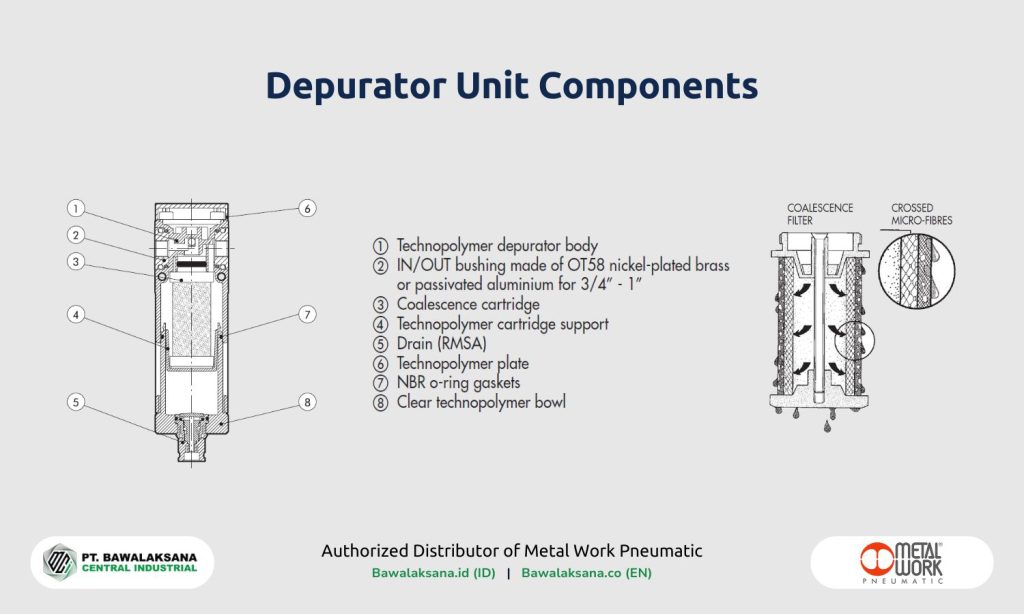

Air Filter Purifier (Depurator)

The function of the depurator is to separate liquid, oil and solid particles that are dispersed (mixed) in the air with a high level of efficiency.

The separation between liquid and solid can occur through a special filtering element called a coalescence cartridge.

These cartridges are very effective in removing traces of oil present in compressed air through crossed microfibers.

The application of air filter purifiers is crucial for dirty industrial environments or applications in industries that demand high levels of air purity, such as in the pharmaceutical sector, F&B, semiconductor manufacturing, gas processing and others.

Shut-Off Valve

This device serves to separate the compressed air circuit from the main air supply. Shut-Off Valve is a three-way valve that can release air pressure from downstream in the closed position.

This feature is indispensable for maintenance operations or when the air supply to a pneumatic machine needs to be stopped.

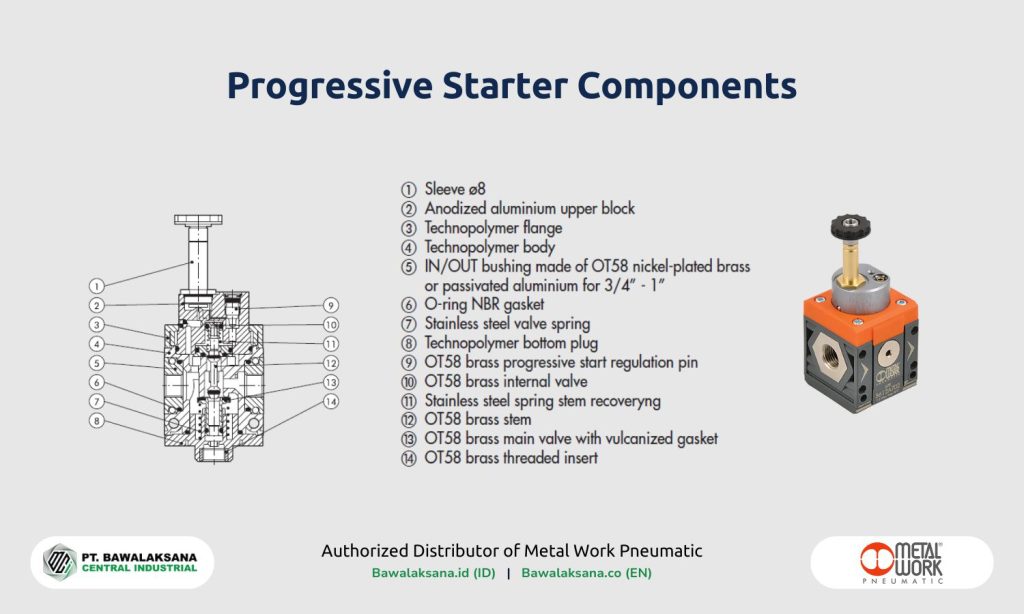

Progressive Starter

The Progressive Starter is an additional component for the FRL Unit that functions to deliver air to the pneumatic lines gradually.

The Progressive Starter feature is very useful for creating a smooth, slow and controlled start-up of pneumatic systems. So that it does not cause excessive pressure surges in the cylinder of the pneumatic cylinder.

With the gradual opening of the valve, the pressure transition can flow smoothly and as needed.

It also serves to enhance the security and safety aspects. That way, components are not easily damaged by pressure surges, and cylinder movement remains controlled and does not endanger nearby operators.

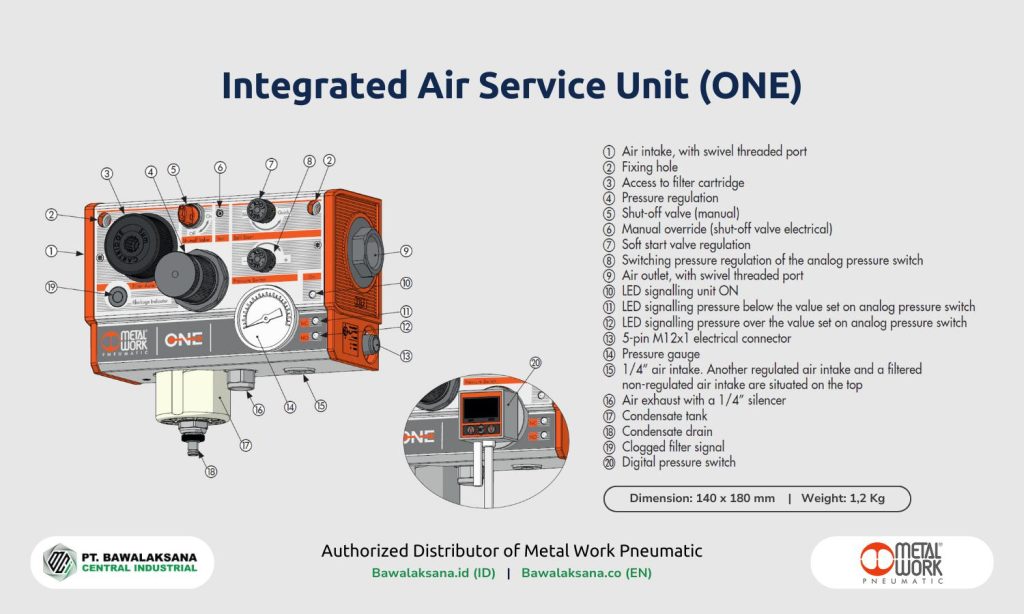

Electric Soft Start Valve

The Electric Soft Start Valve is an integral part of the ONE device and serves the same purpose as the Progressive Starter but with more enhanced functionality.

ONE is an air treatment unit that has a high degree of integration and includes various Air Service Unit functions.

This device is a configurator for air treatment systems and the latest innovation in the world of pneumatics.

The ONE device’s Electric Soft Start Valve can gently regulate the air pressure when the pneumatic system starts up. This technology can adjust the rate of pressure rise based on the airflow rate of downstream equipment.

The advantage is that when downstream there is a lot of equipment that has a constant flow (such as a blower), the Electric Soft Start Valve can still work properly.

The pressure rise can also be controlled precisely and stably, without being affected by the airflow characteristics on the downstream side.

Flux flowmeter

Flux flowmeter serves to measure the basic quantity of pressure flow and air flow rate in pneumatic systems. This technology can measure various critical energy parameters, such as:

- Volume flow (Nl/min)

- Mass flow (Kg/min)

- Pressure (BAR)

- Power (kW)

- Energy (kWh)

- Temperature (°C)

- Total air consumption (Nl)

- Overall mass consumption (Kg)

Not only useful for measuring energy parameters, the Flux Flowmeter is also a very important monitoring tool for predictive diagnosis of pneumatic systems.

Especially to detect air leakage problems, changes in energy consumption and various small problems that have the potential to become worse if left unchecked.

Using the Metal Work FluxUp mobile app, the wireless version can communicate with Ethernet networks (via MQTT protocol) and mobile devices (smartphones and tablets) via Bluetooth®.

Through this app, in addition to displaying the measured parameters in real-time, you can also change all the Flowmeter settings and view the data directly.

Regtronic Proportional Pressure Regulator

Regtronic Proportional Precision Pressure Regulator (PPPR) has a function to regulate air pressure precisely through variables that depend on input commands.

Regtronic PPPR is an advanced technology for pneumatic systems that can be controlled remotely via M12x1 cables and connectors, and can be controlled via Volt, mA, RS232 or via IO-Link.

Regtronic can connect with various types of fieldbus, such as:

- EtherNet/IP

- EtherCAT

- Profinet IO

- CANopen

- Profibus-DP

- Powerlink

- IO-Link

- CC-Linkk

Using the Metal Work RegUp mobile app , the wireless version can communicate with Ethernet networks (via the MQTT protocol) and mobile devices (smartphones and tablets) via Bluetooth®.

Through this app, you can view and change the set pressure in real-time, set all operating parameters as well as view pressure change trend graphs.

Both the Flux Flowmeter and Regtronic are advanced components that can connect pneumatic systems with technology, thanks to their IoT Based Monitoring and Notification System capabilities.

We have discussed application examples of these two technologies in our article, Pneumatic Automation System in the Dairy Processing Industry.

We need to inform you that there are still a lot of Air Service Unit components and technologies other than those we have mentioned above. What we have mentioned here is just a small part of it. It is important to consult with the engineers in your company to get a complete solution according to the system needs.

Improve Productivity, Performance and Safety Aspects Using Air Service Unit

The performance of a pneumatic system is greatly influenced by the quality and condition of the air used to run the system.

The Air Service Unit device not only functions to treat the air to become cleaner, this component also plays a role in controlling air flow so as to improve safety aspects.

When air is not managed properly, the system’s performance will quickly degrade, components will wear out easily and energy will be wasted.

According to the publication titled, Enhanced Energy Conservation and Response Accuracy of A Pneumatic Control System, the energy consumption of pneumatic systems in the industrial sector can reach very significant values.

In America alone, its energy consumption accounts for about 9% of the total national industrial electricity consumption, while in Europe it reaches about 10%.

At the same time, pneumatic systems have been widely applied in various industrial sectors around the world. Therefore, simultaneous efficiency improvements can have a huge impact in terms of energy savings and carbon emissions.

Implementing an Air Service Unit on a pneumatic system can be the best solution to answer this challenge. So that energy efficiency can be achieved without compromising quality and productivity on the factory floor.

PT. Bawalaksana Central Industrial is the authorized distributor for Metal Work Pneumatic which can supply various pneumatic system technologies and components for various industrial sectors.

We can provide support for your company from planning, implementation to maintenance.

If you have a plan to implement a pneumatic system that can be connected to the digital ecosystem, we can provide comprehensive support.

Please talk to our Application Engineer team by clicking the consultation button below. Together, let’s create an energy-efficient industrial environment without compromising on production quality.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)

![Problems with 3 Phase Contactors and How to Solve Them [Practical & Effective]](https://bawalaksana.co/wp-content/uploads/2025/07/Masalah-Pada-Kontaktor-Motor-3-Phase-dan-Cara-Mengatasinya-Bawalaksana-ID-1080x675.jpg)