Pneumatic devices are engineered for high durability and require minimal maintenance; however, it is essential to note that pneumatic components are not entirely maintenance-free.

On the contrary, pneumatic systems and devices necessitate proper and regular maintenance to optimize their efficiency and performance.

According to data from Viking Analytics, appropriate maintenance of industrial machinery can extend its lifespan by approximately 20% to 40%. Routine and correct maintenance can mitigate costs and reduce the need for new parts within industrial automation systems.

Several common mistakes should be avoided when maintaining a pneumatic system, including:

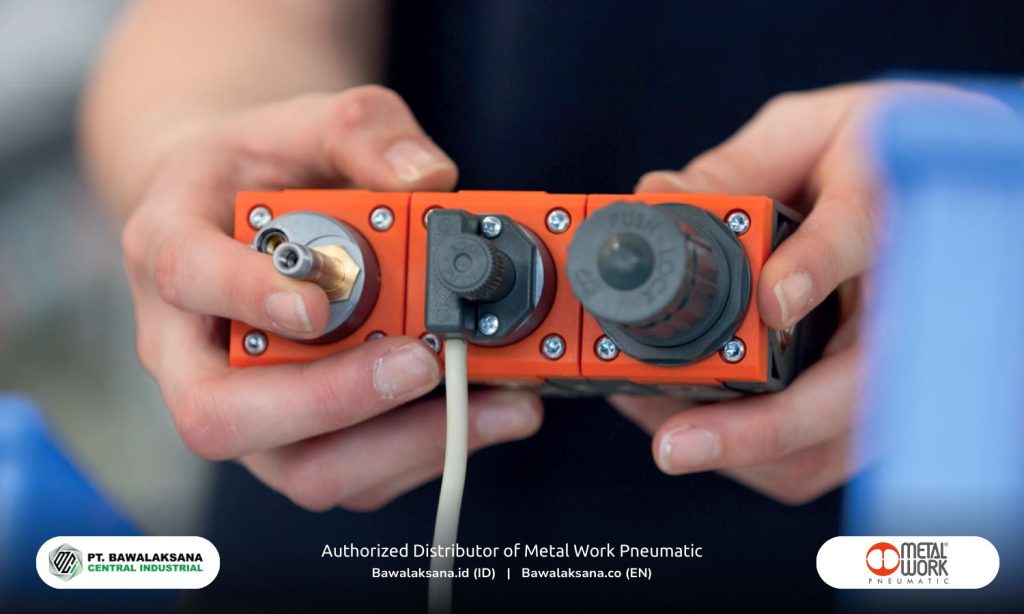

- Neglecting routine FRL (Filter, Regulator, and Lubricator) unit area cleaning.

- Utilizing components incompatible with the application environment.

- Relying on the default pneumatic tubing provided by the vendor, even when it is unsuitable for extreme conditions.

- Failing to inspect and replace worn components regularly.

- Ignoring adequate lubrication as specified by manufacturer guidelines.

Improper maintenance of pneumatic devices can lead to diminished system performance or increased maintenance costs. Avoiding common mistakes is crucial to preventing these issues from adversely impacting the pneumatic devices in your organization.

If this is your first visit to Bawalaksana’s website, we recommend reviewing the previous article for comprehensive context.

This discussion continues our previous article, 10 Essential Steps for Maintaining Your Pneumatic Systems.

Failure to Comprehend Specific Maintenance Requirements

Each component within a Pneumatic System has distinct characteristics and maintenance needs. Adherence to the manufacturer’s recommendations for the equipment is essential to ensure adequate upkeep.

Neglecting the manufacturer’s maintenance guidelines may result in diminished performance or potential damage to pneumatic devices. For instance, the Air Service Unit (FRL) necessitates daily inspection and cleaning to operate optimally.

The engineering team at Bawalaksana Central Industrial strongly advocates for frequent and daily attention to the Air Service Unit to sustain its effectiveness. The FRL unit fulfills three critical functions in maintaining the cleanliness and dryness of the pneumatic system’s air supply.

Ensuring clean and dry air is vital for safeguarding product quality and enhancing system performance.

Utilization of Low-Quality Spare Parts

Specific organizations tend to employ inexpensive spare parts when replacing worn or damaged components to reduce operational costs.

Frequently, these organizations rely on default pneumatic tubing provided by suppliers despite its unsuitability for extreme environmental conditions.

Regrettably, this cost-saving strategy may lead to a plethora of long-term complications. Low-quality spare parts typically exhibit shorter lifespans and are more susceptible to failure.

Moreover, the utilization of substandard components can result in contamination of production processes and a decline in product quality. Instead of reducing costs, such an approach can significantly escalate maintenance expenses and jeopardize product integrity.

Reasons for This Trend

Frequently replacing damaged components may increase production downtime and diminish overall productivity. Additionally, compromised product quality can result in customer dissatisfaction.

Based on extensive experience, prioritizing original and high-quality spare parts proves far more cost-effective and enhances customer satisfaction, even when the initial investment is more significant. Investing in premium components ensures superior system performance, operational efficiency, and reliability. Consequently, factory productivity is enhanced, which drives economies of scale and increases business profitability.

For instance, procuring low-quality pneumatic tubing entails numerous risks, including:

- The presence of toxic or heavy metal content is due to non-hygienic materials and manufacturing processes.

- Increased vulnerability to breakage from humidity, high temperatures, or elevated pressure.

- Non-compliance with essential industrial standards such as FDA Approval, CE Regulation 1935/2004, CE Regulation 10/2011, Self-Extinguishing UL94 V0, and relevant DIN standards.

The selection of high-quality pneumatic components extends beyond industrial hoses and tubing; it encompasses all elements of automation systems that are integral to the production process.

Performing Maintenance Adhering to Established Procedures

Prioritizing safety is an essential principle when conducting maintenance on pneumatic equipment. Neglecting to follow established maintenance procedures can result in various adverse consequences, including:

- Damage to components

- Failure of the system

- Accidents leading to physical injuries

- Decreased quality of the final product

- Escalated production costs

We recommend the following steps for maintenance activities related to pneumatic systems:

- Review Documentation: Thoroughly examine the schematic diagrams for each component, as delineated in the manufacturer’s guidelines.

- Read the Service Manual: Acquire a comprehensive understanding of pneumatic components’ function and operational principles and their interrelations with other system elements.

- Conduct Diagnosis and Inspection: After reviewing the documentation and service manual, perform visual inspections, diagnostics, and repairs to ensure safety and correctness.

- Release Stored Pressure: Before commencing maintenance, confirm the discharge entirely of all residual pressure in the air storage tank.

- Secure Mechanical Loads: Lock any unsecured mechanical loads to avert the potential for accidents or physical injuries.

Important Reminder:

Cleaning pneumatic components without verifying residual air pressure may result in severe damage or injury. Furthermore, incorrectly reassembling components—without adhering to the prescribed order or method—can lead to operational failures. Therefore, following the manufacturer’s recommended maintenance procedures is imperative.

If necessary, consider providing training for technicians or operators to ensure they thoroughly understand the correct maintenance protocols.

Neglecting Regular Inspections

As previously stated, routine inspections are essential for the early detection of issues within pneumatic equipment. Regular maintenance and inspections are pivotal in preventing more significant damage.

Nevertheless, numerous organizations overlook this routine practice due to concerns about efficiency or resource constraints. This oversight represents a critical error that must be avoided. Establishing a scheduled inspection plan and ensuring consistent adherence to it is strongly advisable.

Key aspects of regular inspections:

- Monitoring air pressure before and during system operation

- Inspecting air filters, lubricators, and water traps within the FRL unit

- Checking for the presence of water mist or moisture within pneumatic tubing

- Identifying air leaks, particularly in instances of audible hissing sounds or sluggish cylinder movement

- Conducting visual inspections for signs of wear or damage on tubing, fittings, valves, and cylinders

- Performing functional tests before the initiation of system operation

Neglecting to Engage Seasoned Professionals

Although pneumatic system maintenance may appear straightforward, it necessitates substantial expertise and experience. Maintenance without the requisite knowledge entails a significant risk of damage or potential accidents.

Therefore, it is essential to seek the assistance of qualified maintenance professionals, particularly for complex or high-risk tasks. These experts possess the fundamental knowledge and experience to ensure the execution of maintenance accurately and safely.

Furthermore, collaborating with firms specializing in pneumatic system implementation or product supply can be advantageous. This collaboration enables operators to receive appropriate guidance and practical solutions for any challenges.

Additionally, the engineering team will receive valuable knowledge from these experts, enhancing overall company productivity.

Neglecting Proper Documentation of Maintenance

Adequate documentation is crucial for monitoring the maintenance history and ensuring consistency in the management of pneumatic system maintenance. However, numerous organizations often neglect this critical aspect, resulting in challenges when evaluating previous maintenance activities and implementing necessary enhancements.

It is imperative to document the following key details:

- Date of maintenance

- Type of maintenance conducted

- Components involved or replaced

- Issues identified or observations noted

- Essential points for evaluation

By maintaining comprehensive records, organizations can identify patterns and trends that will contribute to the continuous improvement of future maintenance programs.

Neglecting Workplace Safety

Did you know that pneumatic systems have the potential to store significant amounts of energy in the form of compressed air?

This stored pressure is a powerful force that, if not managed correctly, can cause serious injuries or considerable damage to company property.

Before commencing any maintenance work on pneumatic equipment, it is crucial to ensure that all compressed air has been fully released from the system. This process, often called “depressurizing,” should be conducted carefully to avoid unexpected pressure releases, which can be dangerous and damaging.

In addition to depressurizing the equipment, it is strongly recommended that you wear appropriate personal protective equipment (PPE) tailored to the specific maintenance tasks you will be performing. Depending on the job, this may include safety goggles, gloves, and hearing protection. Proper PPE can significantly reduce the risk of injury and ensure a safer working environment.

Furthermore, do not overlook the importance of adhering to the maintenance procedures outlined by your pneumatic equipment manufacturer. These guidelines contribute to each machine’s safe operation and maintenance practices, thus minimizing hazards.

Neglecting to Update Knowledge and Skills

A prevalent error in the industry is the failure to keep knowledge current amid the continuous advancements in pneumatic technology.

Although the fundamental principles underlying pneumatic systems have not significantly changed since their inception, recent innovations have markedly enhanced performance and operational efficiency.

Additionally, the complexity of modern pneumatic components has increased.

The business may jeopardize its competitive edge if an organization’s engineers and machine operators are not informed about these industry developments.

Therefore, providing comprehensive training and certification opportunities for technicians and operators is highly advisable. This approach ensures that individuals responsible for pneumatic systems have the most up-to-date knowledge and skills, mainly when working with advanced and contemporary pneumatic components.

Neglecting the Need for Upgrades or Replacements

In certain instances, routine maintenance may prove insufficient to address subpar system performance and diminished productivity. Outdated and worn components must be replaced with modern, advanced technologies.

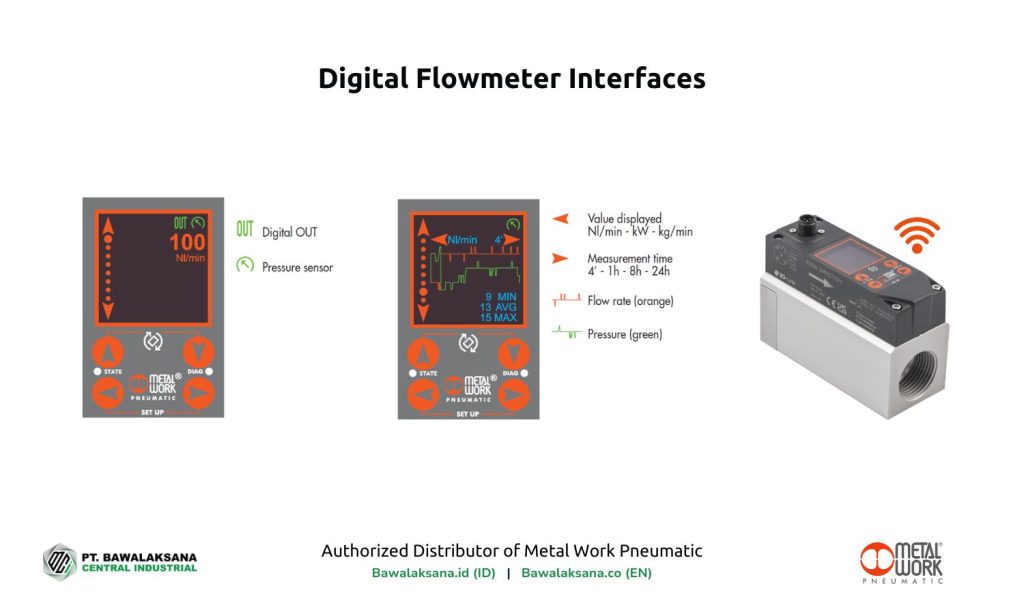

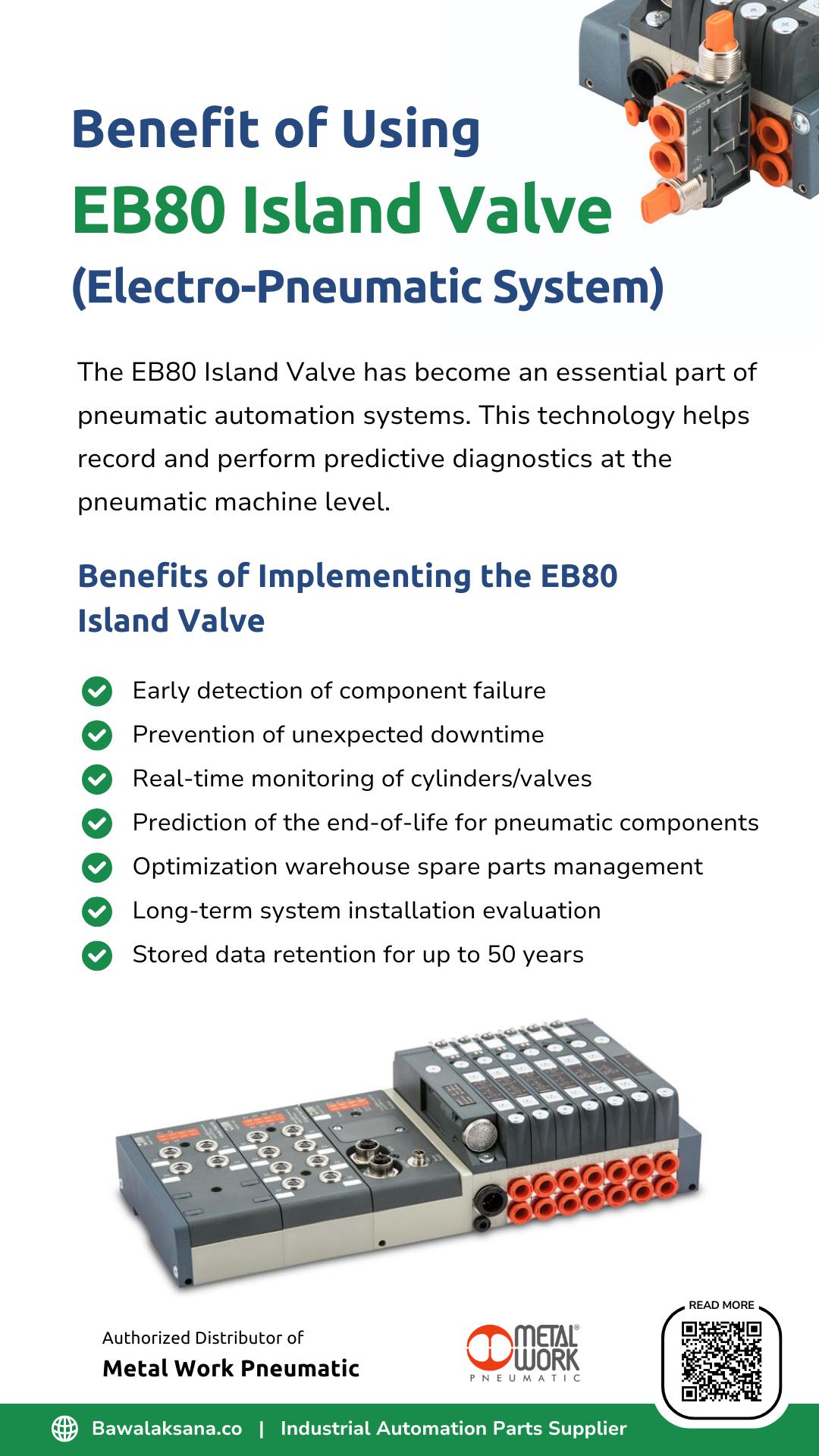

The progression of pneumatic innovations is becoming increasingly sophisticated, particularly in response to the growing demand for Industrial Internet of Things (IIoT) applications.

These enhancements encompass sensor integration, electro-pneumatic systems, and advanced digital technologies. By implementing these upgrades, organizations can adopt Smart Pneumatic, thereby significantly enhancing productivity on the factory floor.

Furthermore, businesses may utilize pneumatic machine algorithms to analyze usage cycles, conduct predictive maintenance, and evaluate energy consumption.

Among the essential technologies for Smart Pneumatic are the Flowmeter FLUX and the EB80 Island Valve. These components are instrumental in recording critical machine-level data, which includes:

- Usage statistics

- Diagnostics

- Lifetime data

By gathering comprehensive real-time data throughout a machine’s operational lifespan, organizations can more effectively identify energy consumption trends, optimize usage cycles, and manage production costs.

With an upgraded workforce skill set and state-of-the-art equipment, companies can significantly enhance their competitive advantage and advance toward sustainable smart manufacturing.

For a deeper exploration of this subject, please refer to our article, Strategic Actions to Improve Pneumatic System Efficiency

Lack of a Well-Planned Maintenance Strategy

A well-structured maintenance strategy is essential for pneumatic systems, as it significantly enhances component performance and extends operational lifespan. Organizations can use a systematic approach to optimize the Return on Investment (ROI) from their pneumatic equipment and machinery.

Two primary maintenance strategies can effectively minimize failures in pneumatic systems:

- Preventive Maintenance: This strategy involves routine actions designed to avert equipment failure. Such actions include overhauls, oil replacement, adjustments, and cleaning of contaminated components.

- Predictive Maintenance: This approach employs data monitoring to assess equipment conditions in real-time. Maintenance is conducted only when necessary, reducing costs and minimizing downtime.

Ideally, these strategies should be integrated, as not all pneumatic devices have built-in sensors that facilitate precise predictive maintenance.

Preventive maintenance tends to be more effective for equipment exhibiting predictable failure patterns or when the costs associated with system failure are relatively low.

Conversely, predictive maintenance is more advantageous for addressing unpredictable failures or in situations where the costs of system failure are significant.

In addition to minimizing downtime, pneumatic maintenance within manufacturing should also prioritize the following objectives:

- Enhancement of workplace safety

- Reduction of accidents

- Optimization of spare parts management

- Prevention of environmental hazards, including property damage or contamination

It is inadvisable to conduct maintenance solely in response to existing issues or to rely exclusively on reactive repairs; such practices are not considered best practices in maintaining pneumatic systems.

Ultimately, a focus on prevention is preferable to one centered on repair. Even components with straightforward functions are susceptible to sudden failures that may result in complete production downtime, disrupting business operations.

Avoid Common Mistakes in Pneumatic Maintenance

This article outlines the ten most prevalent mistakes encountered in the maintenance of pneumatic systems.

Please remember that pneumatic technology has developed significantly since its inception between the 10th and 70th centuries AD, reaching substantial advancements in the 19th century and continuing to evolve in contemporary applications.

Despite being considered one of the most cost-effective and environmentally friendly automation solutions, pneumatic systems necessitate diligent maintenance to optimize their performance and functionality.

By avoiding the common errors detailed in this article, your organization can enhance the advantages of pneumatic systems while reducing the likelihood of unanticipated failures or operational downtime.

What To Consider Next?

We strongly recommend reviewing our comprehensive article, Pneumatic System Applications in Electronics Manufacturing and Their Functions. This piece elucidates the critical role of pneumatic devices in producing modern electronic products.

Indeed, the absence of pneumatic technology would make manufacturing even the most advanced innovations considerably more challenging.

We encourage you to read the full article to gain invaluable insights into the significance of pneumatic systems in today’s industrial landscape.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)