A pressure gauge is a crucial instrument used to measure and monitor the pressure of fluids—be they liquid or gas—in a closed system. This instrument is prevalent in industrial settings and is integral to warning systems.

The primary function of a pressure gauge is to ensure that industrial processes operate safely, maintain high quality, and avert potential leaks or explosions that could pose serious safety threats.

Did you know?

For over 150 years, pressure gauges have been indispensable parts of industrial operations.

In 1850, a French engineer named Eugène Bourdon patented a pressure-measuring device featuring a hollow, C-shaped tube. This innovative design, which became widely known as the Bourdon tube gauge, is a testament to our rich industrial heritage.

According to Britannica, Bourdon tube pressure gauges have been utilized for over one and a half centuries. Since then, they have been effectively applied to measure the pressure of various fluids, such as steam, water, and air, with capacities reaching as high as 100,000 psi (6,800 bar).

Recognizing the significance of pressure gauges in industrial processes, the Bawalaksana team will explain what a pressure gauge is, explore its functions, and explain how it operates.

What is the Function of a Pressure Gauge in Industry?

Pressure gauges are pivotal in ensuring that fluid pressure in industrial processes remains within a safe limit. They also serve as early warning systems, detecting pressure fluctuations that could pose hazards or disrupt production.

Here are some key functions of a pressure gauge in critical industrial sectors:

- Detects excessive pressure that could lead to fire or explosions.

- Identifies pressure drops caused by leaks or system malfunctions.

- Assists industrial operators in maintaining safe, high-quality operations that comply with standard procedures.

- Ensures product quality, facility safety, and personnel well-being.

Pressure gauges are widely used across various vital industrial sectors, including:

- General Industrial

- Chemical & Petrochemical

- High Purity / Sterile Processes

- Food, Beverage & Dairy

- Heating Installations / HVAC

- Filter Systems

- Pharmaceutical

- Oil & Gas

- Shipping

- Power Generation

- Others

Understanding Gauge Pressure and Vacuum Pressure

The pressure measured by a pressure gauge is relative to atmospheric pressure, commonly called gauge pressure.

- If the measured pressure is above atmospheric pressure, the value is positive (+).

- If the measured pressure is below atmospheric pressure, the value is negative (-).

- When pressure is measured below atmospheric levels, it is called vacuum pressure, expressed in negative (-) values.

Most pressure gauges in the market are specifically designed to measure gauge pressure.

It’s also important to note that atmospheric pressure fluctuates with altitude, typically averaging around 101.352 kPa, which is equivalent to 1 BAR.

For a more comprehensive understanding, check out our article on the Basics of Measurement: Absolute, Gauge, and Differential Pressure.

Why Pressure Gauges Are Essential in Industry?

Have you ever considered the potential consequences of pressure fluctuations in industrial processes?

Excessively high pressure can damage equipment, compromise product quality, and present significant safety hazards in critical sectors like pharmaceuticals and petrochemicals.

Conversely, if the pressure is too low, it can render processes inefficient or even halt production altogether.

Take pharmaceutical manufacturing, for instance: low pressure can disrupt essential chemical reactions, resulting in products that fail to meet strict safety standards.

It highlights pressure gauges’ crucial role in monitoring and regulating system pressure, ensuring that production proceeds without a hitch while maintaining high quality.

When dangerous pressure spikes occur, industrial operators can swiftly identify them through the readings on pressure gauges.

Similarly, if the operating pressure dips too low, they can quickly prevent production setbacks. This underscores the importance of pressure gauges as vital components of industrial warning systems, safeguarding operations and ensuring high-quality outputs, as outlined earlier in this discussion.

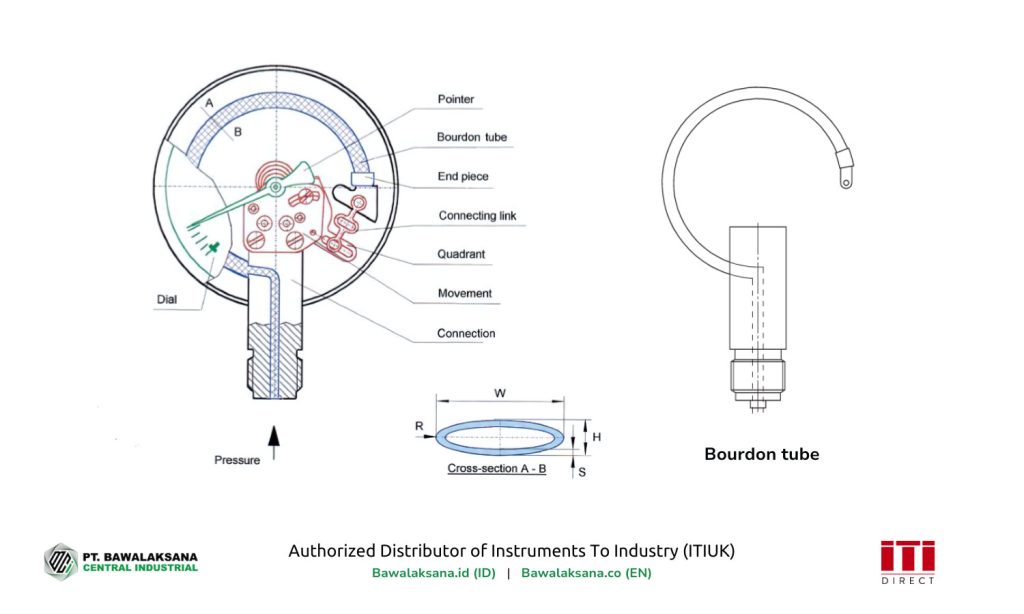

Key Components of a Bourdon Tube Gauge

Before diving into how a pressure gauge functions, it’s essential to grasp the key components of a Bourdon tube gauge. In this overview, we’ll spotlight the most crucial elements of this type of pressure gauge, with a more in-depth discussion of all its parts to follow in a separate article.

Here are the vital components of a Bourdon tube gauge:

- Bourdon tube: An elastic, hollow, C-shaped tube that deforms when pressurized fluid enters it.

- Mechanical Components: These link the Bourdon tube to the pointer on the gauge’s face. This mechanism comprises several small parts, including the connecting link, quadrant, movement, rack, and gear. Together, they transform the tube’s deflection into rotational movement, which drives the pointer (indicator needle) across the gauge.

- Dial Gauge: This is the visible face of the pressure gauge, featuring the pointer, numerical scale, and calibrated markings for reading pressure measurements. As the Bourdon tube responds to pressure changes, the pointer moves around the dial, reflecting the measured fluid pressure.

- Inlet: This is the first point of contact for the pressurized fluid, leading directly into the Bourdon tube. The inlet allows fluid to flow in, initiating the pressure measurement process.

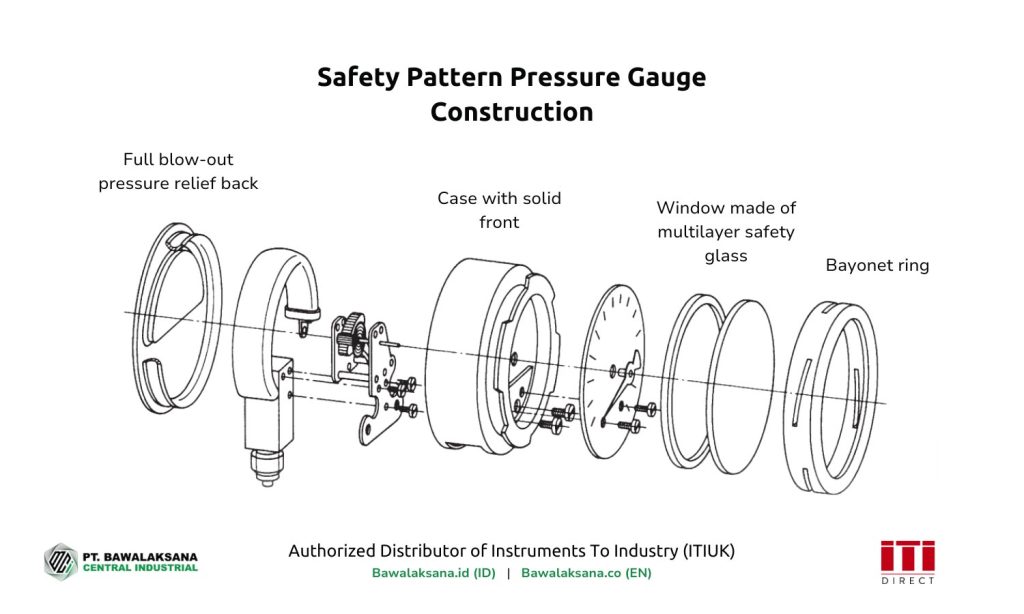

The Bawalaksana team has thoroughly discussed the complete structure of a pressure gauge, touching on commonly used materials, accuracy classes, construction and design, and safety patterns for critical applications.

For a comprehensive explanation, please see our article, Understanding Pressure Gauge Anatomy: Accuracy, Components, Materials & Design.

How Does a Pressure Gauge Work?

Fundamentally, a pressure gauge operates based on Hooke’s Law, where the deflection of the Bourdon tube deforms proportionally to the applied pressure.

According to Britannica, Hooke’s Law was discovered by the British scientist Robert Hooke in 1660. This law states that the deformation of an elastic object is directly proportional to the force or load applied. Once the force is removed, the object returns to its original shape and size.

The working principle of a Bourdon tube pressure gauge follows these steps:

- Pressurized fluid enters the pressure gauge through the inlet (socket), which is connected to the elastic, C-shaped Bourdon tube.

- The fluid pressure deforms the Bourdon tube, causing it to change its curvature in proportion to the fluid pressure.

- The deformation of the Bourdon tube shifts the mechanical components, which rotates the pointer shaft (indicator needle) on the dial gauge face to display the pressure reading.

- The operator reads the pointer on the dial gauge and interprets the measurement according to the selected pressure range and unit.

- When fluid pressure decreases or disappears, the deformation of the Bourdon tube reverses, causing the C-curve to return to its original shape. It is indicated by the pointer returning to “0” (zero) on the dial gauge.

The diagram below illustrates the Bourdon tube components and the mechanical components connecting them to the pressure gauge dial face.

The diagram above illustrates how the end of the Bourdon tube’s C-shaped curve is mechanically linked to the pointer on the dial gauge (the glass window). When the Bourdon tube deforms in response to changes in fluid pressure, the pointer rotates accordingly to indicate the measured pressure value.

As fluid pressure increases, the tube deforms more significantly. It is then read on the calibrated dial according to the designated measurement unit, whether PSI, MPa, BAR, or another unit.

As a vital instrument in many industrial applications that often face harsh conditions, the Bourdon tube and the mechanical components within the pressure gauge inevitably wear and tear over time.

Regular calibration should be conducted at established intervals to maintain accurate and reliable readings. This practice ensures that the pressure gauge stays in peak condition, which is crucial for keeping production processes running smoothly and efficiently.

How to Use a Pressure Gauge for Accurate Pressure Measurement?

As noted before, measuring pressure in the industrial sector ensures operational safety and production quality. So, how do you use a pressure gauge correctly to achieve precise pressure readings?

It’s essential to understand that effectively using a pressure gauge in industrial settings demands skill and the right equipment. If not done correctly or if the wrong gauge is selected, pressure measurements can vary widely, leading to potential issues.

Key Considerations Before Measuring Pressure:

- Type of Fluid: Assess if it is corrosive, has a high viscosity, or contains a slurry, and select the appropriate pressure gauge for measurement.

- Operating Pressure Range: It is essential to ensure that the selected pressure gauge suits the operating conditions. The working pressure should not exceed 75% of the gauge’s maximum range to ensure accuracy and safety.

- Accuracy Class: In applications where precision is critical, a high-accuracy class pressure gauge is imperative to guarantee precise, consistent, and reliable measurements.

- Environmental Factors: Industrial pressure measurements are subject to various challenges, including vibrations, deep-sea conditions, or extreme environmental factors. You must take precautions to safeguard the gauge against potential damage.

- Selecting the Appropriate Pressure Gauge: All factors above must be considered to ensure accurate and consistent measurements.

Additionally, we have produced a comprehensive guide entitled, How to Read an Industrial Pressure Gauge with Accuracy and Precision, which encompasses the following topics:

- Fundamentals of pressure measurement

- Correct techniques for reading a pressure gauge

- Strategies to avoid reading errors with pressure gauges

For a detailed and comprehensive examination, please refer to the link above.

Final Thoughts on Pressure Gauge Functions and Operation

This document concludes our thorough examination of the functions and operational principles of pressure gauges, as presented by the Bawalaksana team.

To summarize, the following key points are notable:

- Pressure gauges have been vital in industrial operations for over 150 years.

- They are crucial components in warning systems, ensuring that industrial processes are safe and efficient.

- The operational principle of a pressure gauge is grounded in Hooke’s Law, which posits that an object’s deformation is proportional to the force applied. This principle is exemplified by the C-shaped Bourdon tube, which deforms in response to fluid pressure.

- Accurate pressure measurement depends on the operator’s skill and the appropriate instrumentation selection.

After you understand pressure gauge functions and operational principles, we recommend consulting our related article, 9+ Types of Industrial Pressure Gauges and Specifications. This guide is essential for selecting the most suitable gauge for your industry.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)