Pneumatic systems are the backbone of industrial automation with many advantages. Despite its high performance and reliability, the system is prone to problems if it does not have an air preparation unit.

The integration of an Air Preparation Unit (FRL Unit) becomes a fundamental requirement in a pneumatic system to ensure clean and well-controlled air.

Clean air is beneficial for maintaining component durability and overall system productivity. Meanwhile, well-controlled air contributes to improving safety and security aspects.

FRL Units are likened to lungs for humans. Without it, the system quickly experiences problems and decreased productivity.

Quoting from Air Filter Engineering, that the air used for pneumatic systems can contain moisture, dust and contaminants that can damage pneumatic system components.

In general, every cubic meter of air in an industrial environment contains millions of particles and about 80% of them are smaller than 2 microns (small enough to pass through a standard intake filter).

Therefore, a Pneumatic Air Service Unit is needed which functions to filter and manage air to make it clean, and can control the air flow rate to improve safety aspects.

Realizing how crucial clean and controlled air is for pneumatic systems, the Bawalaksana.id team would like to explain why FRL Units are so vital in pneumatic applications in various industrial sectors.

Prevents Water and Dirt Accumulation that Leads to Component Damage

The first reason why the Air Service Unit is critical for pneumatic systems is to prevent the accumulation of water and dirt from the air.

Airborne particles such as moisture, dust and oil are major challenges for pneumatic systems. Dirty air can accelerate wear and damage in various moving pneumatic components (cylinders and valves).

The following points will explain how any substance, dirt or air particles that are not managed properly can affect the overall performance of the system.

Dust and Solid Particles

Dust and solid particles accumulated on pneumatic lines have the potential to increase friction and blockage of the airways.

Dust entering the pneumatic cylinder will accelerate the deterioration of seals and gaskets. This leads to increased mechanical friction, air leakage and reduced cylinder performance.

Moisture and Water Accumulation

Moisture entering the pneumatic line can cause water accumulation. Then, the pressurized air will push the water to various places downstream of the pneumatic system, such as:

- Pneumatic hose

- Pneumatic cylinder

- Solenoid valve

- Air tools

- Fittings

- and others

The presence of water in the system is like “washing” the lubricating substance on the components. In fact, it can even cause oxidation and rust on metal surfaces.

When the lubricant is washed away by water, the moving components may also experience increased friction, resulting in degraded system performance.

Pneumatic hoses are also subject to rupture when dimensional changes occur due to humid and wet air. Especially for hose types that have high hygroscopic properties.

In addition, industrial environments tend to be hot or very cold. This will accelerate the deterioration of the hose, causing cracks or ruptures.

If this condition is not anticipated properly, the pneumatic system can experience failure or downtime outside the plan. The production process becomes disrupted or stops completely, causing financial losses.

Oil Contamination

Oil or grease particles can mix with the air inside the pneumatic line. This can happen due to a dirty environment or from compressor engine splashes.

Oil and grease contained in the air can contaminate components and increase mechanical friction in cylinders, valves and other pneumatic components.

Oil contamination can accelerate the deterioration of seals on cylinders, causing them to become stretched or damaged. This will lead to air leakage and decreased cylinder actuator performance.

The three things above (dust, moisture and oil) if allowed to enter the pneumatic circuit will cause various very serious problems, such as:

- Stuttering, dragging and squeaking cylinder movements appear due to increased mechanical friction.

- Decreased solenoid valve performance resulting in energy waste and less responsive system performance

- Air supply interruption or system failure due to blockage

- Pneumatic hoses are easily broken or damaged

- Contamination in the production process that causes manufacturing defects

Thus, we have understood that managing air for pneumatic systems is a must-do in order to avoid a series of problems throughout the system.

Improving Air Quality and Production Process Quality

Pneumatic systems have become an important part of automation systems in electronics, pharmaceutical and F&B manufacturing.

However, these sectors rely heavily on clean, dry air to achieve quality processes and products.

The slightest contaminant can result in production defects that lead to financial losses, both on the part of the company and consumers.

The Air Service Unit, which is an integral part of the pneumatic system, can answer these challenges.

This component can filter airborne particles measuring 50 μm to 5 μm. In fact, by using the Active Carbon Filter, air can be purified from particles as small as 0.01 μm.

Air Service Unit Pneumatic will also retain the liquid impurities contained in the compressed air into condensate which contains the deposited impurities. Then, the condensate can be discharged through the drain valve.

To purify air mixed with oil, a purifier filter equipped with a Coalescence Cartridge is available. This cartridge is specially designed to remove traces of oil contained in compressed air.

For information, the electronics, pharmaceutical and F&B manufacturing sectors have higher standards than other sectors. Not only related to hygiene and cleanliness protocols, but also related to safety and sustainability.

Therefore, FRL units that are reliable, equipped with safety functions and can meet high standards are needed in these sectors.

The good news is that Air Service Units from Metal Work Pneumatic can be the best choice, such as the ONE, Skillair and New Deal series.

Provides Precise Lubrication as Required by the System

Lubrication in pneumatic systems helps in maintaining the integrity of the pneumatic system components.

The lubrication mechanism can be executed through the Air Service Unit, by converting the lubricant droplets into aerosols thanks to air pressure.

This lubrication process has many benefits for pneumatic components (especially cylinders and solenoid valves), such as:

- Prevents wear and corrosion

- Minimizes friction between components

- Extends the life of pneumatic cylinders

- Maintain optimal and responsive performance

- Maintain the integrity of seals and gaskets in the cylinder

For your information, it is important to choose the type of lubricant that is compatible with the seal and seal material inside the pneumatic cylinder. So that the seals are not easily stretched, worn and damaged, leading to air leakage and decreased responsiveness.

Air leakage in pneumatic cylinders results in slow and less than optimal movement. This contributes to energy wastage and production cost overruns.

For industries that rely on precision, speed of movement and cylinder reliability, good lubrication contributes to improved energy efficiency, operating and maintenance costs.

In applications in the F&B sector, choosing a type of lubricant that is Food Approved is also very important. To ensure that lubricants do not cause contamination if accidentally mixed into food substances. Meanwhile, in the pharmaceutical industry, there is a regulation that compressed air must be able to achieve proper purity. To achieve this, specialized air compressors designed to meet these standards are required.

The Air Service Unit for this application also needs to use specifications that meet the standards in this sector. To ensure the system works properly, reliably and safely.

Controlling Air Pressure and Air Flow Rate for Energy Efficiency

Air pressure and air flow rate are among Basic Quantity Factors Affecting the Performance Efficiency of Pneumatic Systems.

Through the Air Service Unit device, operators can adjust the air pressure and air flow rate according to the needs of pneumatic applications in the industry.

The more optimized the quantity of air flowing to the various pneumatic components, the more efficient the energy consumption and operational costs on the manufacturing floor.

The FRL Unit helps you to control air wisely, resulting in more energy-efficient production operations and less carbon emissions.

For information, the performance efficiency of a pneumatic system is influenced by three basic quantity factors, namely:

- Air pressure and air flow rate

- Mechanical friction

- Component size

The FRL Unit regulates the air flow rate to downstream components of a large number of pneumatic systems.

In fact, the performance efficiency of downstream components can be affected by the FRL Unit. The better the air quality and control, the better the impact on productivity and energy efficiency.

Improving operational safety and security

Good airflow management in pneumatic systems contributes to improving operational safety and security aspects.

FRL Industrial-grade units can generally be equipped with various additional components to accommodate both aspects. Among the most vital are the following:

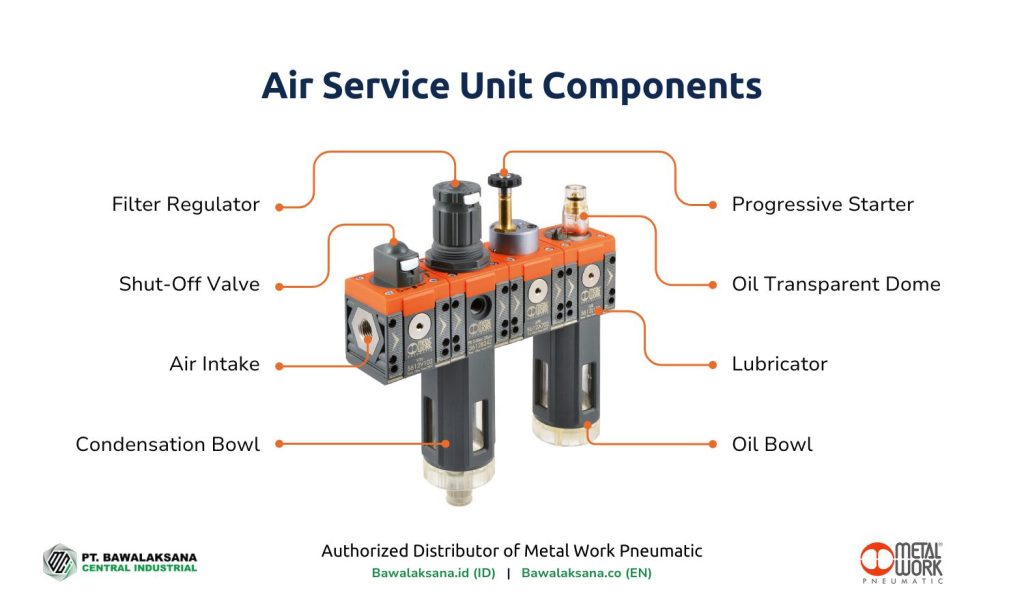

Shut-Off Valve

Shut-Off Valve is an additional component for the FRL Unit which functions to separate the compressed air line from the main source (compressor or air reservoir).

Shut-Off Valves are indispensable in maintenance operations or when the air supply to the downstream section needs to be stopped.

This component has a three-way valve that can disconnect the downstream system from the pressure air supply in the closed position.

Progressive Starter

The Progressive Starter is an additional component for the FRL Unit that functions to gradually flow air into the pneumatic channel. So that the start-up of the pneumatic system takes place slowly and controllably, and does not cause excessive pressure surges.

Progressive Starter equipped with an advanced internal valve that can split the airflow opening operation in two stages:

- First stage: Airflow is opened in a limited manner to the downstream channel.

- Second stage: The airflow is fully opened when the downstream pressure reaches about 40% to 60% of the upstream pressure.

With the gradual opening of the valve, the pressure transition can flow smoothly and as needed.

It also serves to enhance the security and safety aspects. That way, components are not easily damaged by pressure surges, and cylinder movement remains controlled and does not endanger nearby operators.

The Progressive Starter became an important part of the FRL Unit for three or more reasons, such as:

- To prevent the pneumatic cylinder from moving rapidly and uncontrollably during the initial start-up of the pneumatic system.

- Air supply needs to be done slowly and gradually for safety reasons.

- To ensure the cylinder speed is within safe speed limits.

Please note that the second stage of the Progressive Starter’s opening operation may not be achieved due to several reasons. For example, there are large leaks downstream or when there is a lot of equipment that has a constant flow (e.g. blowers).

Electric Soft Start Valve

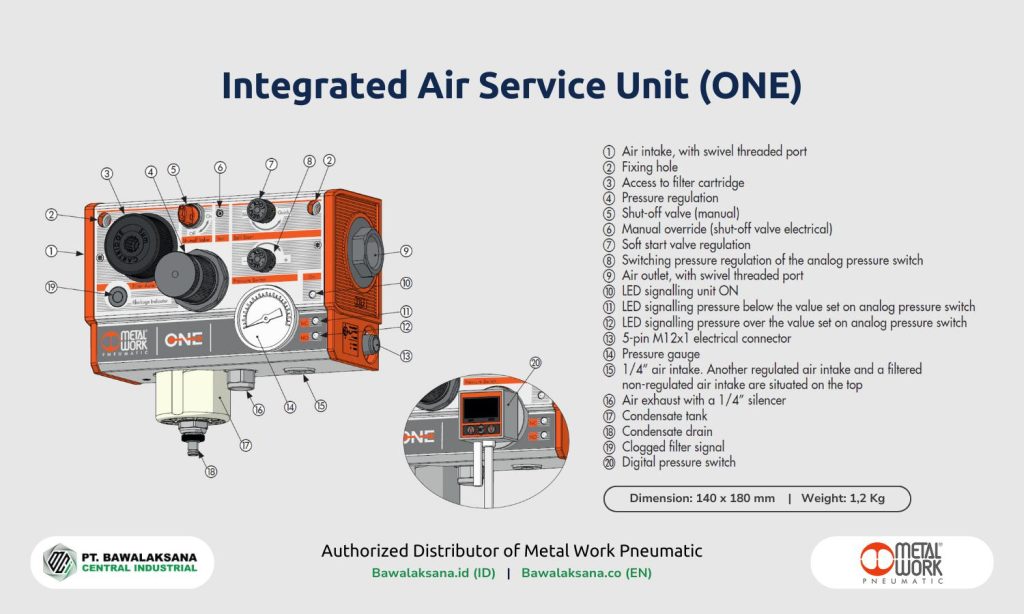

The Electric Soft Start Valve is a feature similar to the Progressive Starter, but with more refined functions. This feature is an integral part of the ONE device.

ONE is an air treatment unit that has a high degree of integration and includes various Air Service Unit functions.

Innovation of Metal Work Pneumatic offers features that are completely new and different, making it worthy of the Fluidtrans Compomac award.

The ONE device’s Electric Soft Start Valve can gently regulate the air pressure when the pneumatic system starts up. This feature prevents excessive pressure surges during system start-up to protect nearby pneumatic components and operators.

The Soft Start Valve of the ONE device can adjust the rate of pressure rise based on the airflow rate of the downstream equipment.

With this advantage, even though downstream there are many equipment that have a constant flow (such as blowers), the Electric Soft Start Valve can still work properly. The pressure rise can also be controlled precisely and stably, without being affected by the airflow characteristics on the downstream side.

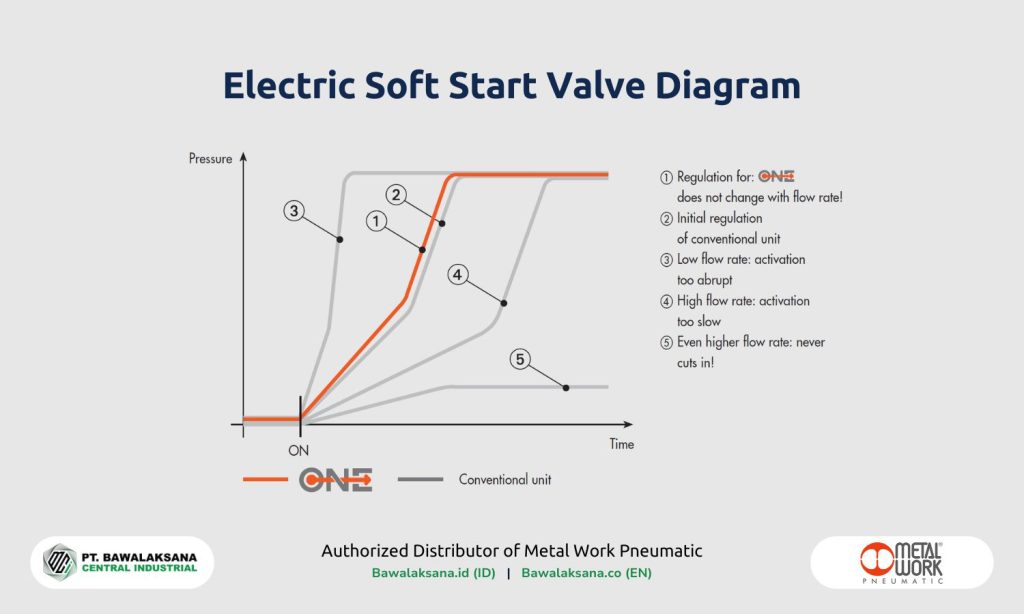

The graph above explains how the air regulation for the Soft Start Valve on the ONE device looks superior compared to the conventional unit. Here’s the explanation:

- Air regulation in ONE is not affected by the flow rate. This means that the start valve function can produce stable and precise pressure regulation without being affected by changes in the air flow rate downstream. The pressure increase during start-up is smooth and consistent, even if the airflow changes (high or low).

- In conventional units, the initial pressure regulation usually depends on the incoming air flow rate. This causes inconsistent and subtle pressure changes, especially when airflow velocity conditions change.

- In conventional units, when the flow rate is low, activation can be too abrupt to reach a certain point. This causes the air pressure jumps in the system to be harsh and sudden.

- In conventional units, when the flow rate is high, the start valve activation is too slow. This results in a slow rise in downstream pressure and a less responsive system.

- In conventional units, when the flow rate is very high (higher flow rate), the start valve usually cannot activate or fails (never cuts in). If this happens, the downstream pressure becomes poorly controlled and the system does not function properly.

For your information, the ONE device has been integrated with various functions and features, such as:

- Filter

- Condensate drain

- Pressure regulator

- Shut-off valve

- Soft start valve

- Pressure switch

- Three supplementary air intakes

- Threaded ports

Despite having a complete set of integrated features in one device, ONE remains compact in size. In fact, it only weighs about 1.2 kg, which is much lighter compared to conventional units that can reach 4 to 8 kilograms.

With dimensions of 140 x 180 mm, the ONE device offers easy setup and minimal maintenance.

ATEX Environment Ready

ATEX environments are areas that are highly sensitive to the accumulation of static electricity and dust on surrounding objects. Electricity and gentle friction in this environment have the potential to ignite sparks and cause fires.

Pneumatic systems are the best choice to accommodate industrial processes in ATEX environments, such as industrial sectors that process oil, gas, methane and hydrogen.

However, not all pneumatic tools and components are allowed, unless they meet ATEX Environment standards. Pneumatic equipment vendors must have Declarations of Conformity and Certificates, to ensure safe and sustainable operations.

The Air Service Unit as an important part of the pneumatic system also needs to meet high standards so that it is suitable for use in ATEX environments.

By using the right Air Service Unit in this environment, operational safety and security aspects can be improved.

Easy Integration with Technology and IIoT

FRL Units can get easy access to integrate with technology and the Industrial Internet of Things (IIoT). You can do this by using additional devices such as Regtronic and Flux Flowmeter.

The Regtronic device and Flux Flowmeter can be connected to the Air Service Unit Pneumatic practically using threaded ports of the appropriate type and size.

Some of the functions of the Regtronic and Flux Flowmeter components are as follows:

Regtronic Proportional Pressure Regulator

Regtronic is a Proportional Precision Pressure Regulator (PPPR) that functions to regulate pressure in pneumatic systems precisely through variables that depend on input commands.

Regtronic is an advanced technology for pneumatic systems that can be controlled remotely via M12x1 cables and connectors, and can be controlled via Volt, mA, RS232 or via IO-Link.

If the Regtronic module is combined with the EB80 Island Valve, it can be connected to various types of fieldbus, such as:

- EtherNet/IP

- EtherCAT

- Profinet IO

- CANopen

- Profibus-DP

- Powerlink

- IO-Link

- CC-Linkk

Using the Metal Work RegUp mobile app, the wireless version can communicate with Ethernet networks (via the MQTT protocol) and mobile devices (smartphones and tablets) via Bluetooth®.

Through this app, you can view and change the set pressure in real-time, set all operating parameters as well as view pressure change trend graphs.

One of the important benefits of Regtronic devices has been discussed in our article, Pneumatic Automation System Applications in the Dairy Processing Industry.

Flux flowmeter

Flux flowmeter is a device that serves to measure basic quantities related to air pressure and air flow rate in pneumatic system operations.

Flux flowmeter is a key technology to improve the efficiency, productivity and scalability of pneumatic systems.

This technology can measure various critical energy parameters, such as:

- Volume flow (Nl/min)

- Mass flow (Kg/min)

- Pressure (BAR)

- Power (kW)

- Energy (kWh)

- Temperature (°C)

- Total air consumption (Nl)

- Overall mass consumption (Kg)

Not only useful for measuring energy parameters, the Flux Flowmeter is a very important monitoring tool for performing predictive diagnosis of pneumatic systems.

Especially to detect air leakage problems, changes in energy consumption and various small problems that have the potential to become worse if left unchecked.

Using the Metal Work FluxUp mobile app , the wireless version can communicate with Ethernet networks (via MQTT protocol) and mobile devices (smartphones and tablets) via Bluetooth®.

Through this app, in addition to displaying the measured parameters in real-time, you can also change all the Flowmeter settings and view the data directly.

One of the important benefits of Flux Flowmeter devices has been discussed in our article, Strategic Actions to Improve Pneumatic System Efficiency.

Both Regtronic and Flowmeter Flux are important parts of the Air Service Unit or FRL Unit, in order to integrate pneumatic systems with technology and IIoT.

Intelligent technology integrated with the pneumatic system contributes to monitoring air quality, pressure variations and component conditions. So that predictive maintenance can be carried out at the right time, and can provide warnings to the engineering team before a failure occurs.

Such flexibility is an important advantage of pneumatic systems that makes them widely favored in various modern industrial applications.

Through the integration of technology and the digital world, pneumatic automation systems have become an important part of a sustainable Digital Factory ecosystem, as well as supporting efforts to create smart manufacturing that is low in carbon emissions (Net Zero Emission).

Best Solution for Air Quality, Control and Management

Air Service Unit or FRL Unit is the best solution for air quality, control and management. These components have been designed to ensure the compressed air entering the pneumatic system is of good quality, controlled pressure and lubrication to suit the needs of the system.

After reading this article, you have realized that the function of the FRL Unit is not just to make the air clean and contaminant-free. But also to control the airflow into the system so as to improve safety and security aspects.

And actually, safety factors are not limited to advanced features, but are also related to the materials used, device durability, safety functions and ergonomics.

By paying attention to all these aspects, the pneumatic system in your company can operate safely, productively and sustainably.

PT. Bawalaksana Central Industrial is the Authorized Distributor for Metal Work Pneumatic which can supply complete solutions for pneumatic system devices and technologies.

We have also become an Authorized System Integrator and Solution Partner for Phoenix Contact which can provide comprehensive solutions for Electrification, Networking and Automation.

If you are interested in implementing a pneumatic automation system that can be connected to the Digital Factory ecosystem, please talk to our Application Engineer team.

Click the consultation button below to start talking to our team of professionals.

Piko Prasetyo

Application Engineer

This article was written in collaboration with Piko Prasetyo, an expert in Automation, Embedded Systems and Artificial Intelligence, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)

![Problems with 3 Phase Contactors and How to Solve Them [Practical & Effective]](https://bawalaksana.co/wp-content/uploads/2025/07/Masalah-Pada-Kontaktor-Motor-3-Phase-dan-Cara-Mengatasinya-Bawalaksana-ID-1080x675.jpg)