The primary distinction between PE and HDPE hoses lies in their specifications and adherence to the ethical standards applicable in industrial settings. It encompasses their operating temperature ranges and working pressures. Notably, HDPE hoses are categorized within the larger family of Polyethylene materials.

Within the PE (Polyethylene) hose category, there are four main types:

- LDPE (Low-Density Polyethylene)

- LLDPE (Linear Low-Density Polyethylene)

- HDPE (High-Density Polyethylene)

- LDPPE (Low-Density Polytube Polyethylene)

Having previously explored the Differences Between PU and PE Hoses in another article, the Bawalaksana Central Industrial team will delve deeper into the distinctions among these four types of PE (Polyethylene) hoses.

Choosing the Right PE Hose: Key Specifications to Consider

Selecting the appropriate PE (Polyethylene) hose ensures your pneumatic system runs smoothly without frequent issues. Choosing the wrong hose can lead to problems like cracking, leakage, or even catastrophic hose rupture.

Recognizing the importance of this matter, we aim to provide a thorough overview of the specifications and applications of PE hoses typically used in industrial environments. This guide will empower you to select the most suitable hose for your ongoing industrial and manufacturing needs.

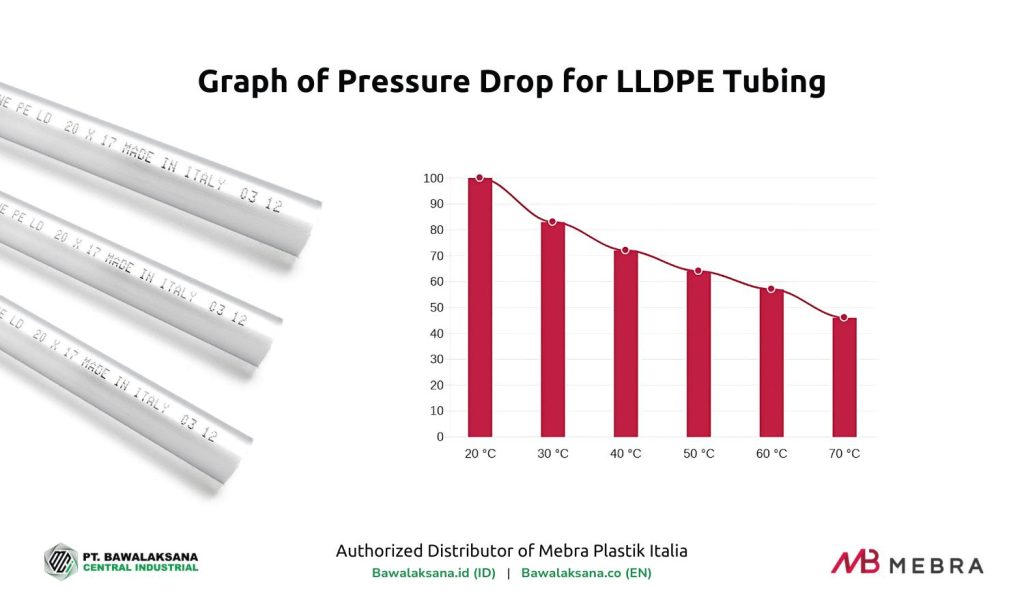

The primary cause of hose failure is pressure exceeding the maximum recommended limit, as indicated by the Pressure Drop Graph. It is important to note that as the operating temperature increases, the working pressure decreases accordingly.

If the operating temperature rises while the working pressure remains constant, it can trigger a sudden rupture of the pneumatic hose. When this occurs, the system may experience severe failure and require proper handling to restore operations.

Understanding that pneumatic hoses can experience diminished performance as the operating temperature rises is crucial. If the temperature increases significantly while the working pressure remains constant, there is a heightened risk of the hose bursting. Thus, consulting the Graph of Pressure Drop is vital for setting air pressure in pneumatic systems at elevated temperatures. It ensures that the hoses are less prone to rupture.

The graph above is an example of Linear Low-Density Polyethylene (LLDPE) hoses produced by Mebra Plastik Italia, a specialized manufacturer of industrial tubing. According to this graph, LLDPE hoses can operate safely at temperatures up to 70 °C; however, the safe working pressure at that temperature is about 47% of the hose’s working pressure at 23°C.

This concept is related to the Safety Factor of Working Pressure. Most pneumatic hoses available on the market have a safety factor ranging from 3:1 to 4:1, which means the hose could burst if subjected to pressures three times or more above the recommended level.

The graph mentioned is an example of Linear Low-Density Polyethylene (LLDPE) hoses produced by Mebra Plastik Italia, a specialized manufacturer of industrial tubing. According to this graph, LLDPE hoses can operate safely at temperatures up to 70°C; however, the safe working pressure at that temperature is about 47% of the hose’s working pressure at 23°C. Essentially, as the operating temperature rises, the hose’s ability to withstand air pressure diminishes.

For instance, consider an LLDPE hose with a diameter of 2 mm × 4 mm, which has a working pressure of 30 BAR at 23°C. When used at 70°C, its capacity drops to around 14.1 BAR or 204.5 PSI. It’s crucial not to apply pressure that exceeds the recommended limits, as this can drastically shorten the hose’s lifespan and increase the chances of rupture.

Additionally, remember that the Graph of Pressure Drop can differ from one hose vendor to another. Always refer to the specific data provided by your hose supplier.

In summary, the pressure drop graph serves as a vital reference tool for effectively managing operating pressure and avoiding pneumatic system failures.

Functions of PE Hoses

PE hoses are versatile components that fulfill various functions across numerous industries. They are commonly used in:

- Industrial automation systems

- Agricultural irrigation systems

- Machinery, equipment, and air tools

- Industrial vacuum systems

- Food processing and drinking water production

While the selection of Polyethylene (PE) hoses may not be as extensive as that of Polyurethane (PU) or Polyamide (PA) hoses, their importance in different sectors cannot be overstated. Understanding the various types and applications of PE hoses is vital for ensuring the smooth operation of your company’s industrial processes.

If you’re interested, you can explore the specific specifications of each type of PE hose by following the links we’ve provided. You can explore their classifications, applications, operating temperatures, working pressures, and pressure drop graphs for each hose type.

Selecting the correct specifications and types of hoses that comply with industry standards can give your company a significant competitive edge. Below is a detailed list of the differences and varieties of PE hoses available in our catalog.

LDPE Hose

Low-Density Polyethylene (LDPE) hose is the most cost-effective option within the PE family and is widely used across various industries. This type of hose boasts an operating pressure capacity of up to 21 BAR (305 PSI) for sizes with an outer diameter of 8 mm and an inner diameter of 4 mm.

LDPE hoses are designed to withstand temperatures -40°C to 60°C. Here are several key points to keep in mind regarding LDPE hoses:

- They offer great flexibility.

- They are not suitable for applications in the food and beverage sector.

- Their resistance to pressure and temperature is limited.

- They have low resistance to abrasion and chemicals.

- Their tensile strength results in relatively low resistance to cracking.

- They are treated to resist degradation caused by exposure to UV light.

- They can handle operating temperatures from -40°C to 60°C.

- With an inner diameter of 26 mm, they can also function at 6 BAR (87 PSI) pressure, requiring a minimum bending radius of 390 mm.

LDPE hoses are a popular and highly valued choice, available in a variety of colors and sizes. You can use the LDPE hoses effectively in applications that involve:

- Hydrolysis resistance

- Chemical resistance

- Industrial automation

- Machine tools

- Vacuum systems

LLDPE Hose (FDA Approved)

The LLDPE (Linear Low-Density Polyethylene) hose stands out as a flexible and elastic option that excels at resisting cracking and enduring chemical exposure. In many ways, LLDPE hoses surpass traditional LDPE hoses, offering enhanced tensile strength, superior impact and perforation resistance, greater thermal stability, and improved resistance to stress cracking.

These hoses boast excellent Environmental Stress Crack Resistance (ESCR). They are FDA-approved, making them ideal for applications in the food and beverage industry where high-pressure systems, sterilization processes, and challenging environments are prevalent. The LLDPE hose can withstand an operating pressure of up to 30 BAR (435 PSI) for a size with an outer diameter of 4 mm and an inner diameter of 2 mm.

Some notable advantages of LLDPE hoses include:

- Tasteless, odorless, and moisture-resistant properties

- Exceptional thermal stability and outstanding resistance to stress cracking, impact, and perforation

- Non-reactive nature with food, compliant with CE Regulation 10/2011

- Safety for use in food and pharmaceutical applications, as certified by FDA Title 21

- Stabilization against degradation from UV radiation due to light exposure

- Operational capability within a temperature range of -40°C to 60°C

- Functionality at 10 BAR (145 PSI) pressure with a 16 mm inner diameter and a minimum bending radius of 180 mm

LLDPE hoses find their application in various areas, such as:

- Food contact

- Potable water systems

- Hydrolysis resistance

- Chemical resistance

- Industrial automation

- Machine tools

- Vacuum systems

HDPE Hose

HDPE (High-Density Polyethylene) hose is recognized for its exceptional durability and excellent chemical resistance, particularly against acidic and alkaline fluids. Compared to LDPE hoses, HDPE hoses perform better under high temperatures and pressures.

These hoses can handle operating pressures of up to 38 BAR (551 PSI) for sizes of 4 mm (outer diameter) x 2.5 mm (inner diameter), 6 mm (outer diameter) x 4 mm (inner diameter), and 8 mm (outer diameter) x 5 mm (inner diameter). They are designed to operate effectively within a temperature range of -40°C to 70°C.

Here are some key points to keep in mind about HDPE hoses:

- They offer flexibility levels that are comparable to LDPE.

- These hoses are not recommended for use in the food and beverage sectors.

- They exhibit strong resistance to both high pressure and temperature.

- Their robust chemical resistance makes them suitable for handling acids and alkalis.

- They can operate at 23 BAR (333 PSI) pressure with a 9 mm inner diameter and a minimum bending radius of 75 mm.

HDPE hoses are ideal for various applications, including:

- Hydrolysis resistance

- Chemical resistance

- Industrial automation

- Machine tools

- Vacuum systems

Overall, HDPE hoses are reliable for environments requiring strong performance and durability.

LDPPE Hose

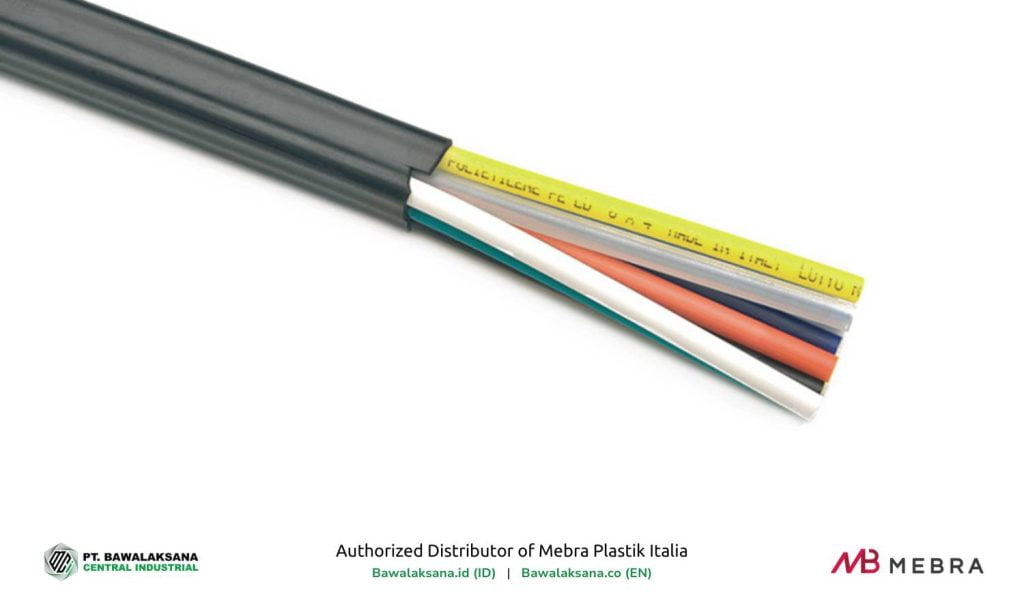

LDPPE (Low-Density Polytube Polyethylene) hose is a versatile multitube hose that can feature up to three channels within a single structure. This design enables enhanced functionality and provides additional protection by incorporating an outer tube as an extra layer of defense.

The primary purposes of multitube hoses include:

- Managing low-pressure pneumatic systems

- Transporting fluids with LDPE-based tubing

The LDPPE multitube hose, measuring 4 mm (outer diameter) x 2 mm (inner diameter), operates at a pressure of up to 21 BAR (305 PSI) and has a temperature resistance range of -10°C to 60°C.

Here are a few key points to keep in mind about LDPPE (multitube) hoses:

- They offer an excellent solution for maintaining hose channels compact and well-protected.

- They are specifically designed to function in low-pressure pneumatic systems.

- They can operate within a temperature range of -10°C to 60°C.

- They can handle 7 BAR (101 PSI) pressure when the inner diameter is 8 mm.

LDPPE hoses are suitable for a variety of applications, including:

- Hydrolysis resistance

- Chemical resistance

- Industrial automation

- Machine tools

- Vacuum systems

Understanding the Differences Between PE and HDPE Hoses

This article outlines the key differences between Polyethylene (PE) and High-Density Polyethylene (HDPE) hoses in industrial automation systems. By now, you should clearly understand the PE hose family, which includes LDPE, LLDPE, HDPE, and LDPPE — each with distinct specifications and applications.

Selecting the correct hose type ensures compatibility with your industry’s operational needs, directly impacting efficiency and system reliability.

Selecting the proper hose for your manufacturing processes can significantly enhance cost efficiency and productivity. Conversely, improper selection may result in system failures and elevated production costs.

Suppose you’re seeking high-quality pneumatic tubing and hoses that meet stringent industry standards, PT. Bawalaksana Central Industrial is here to assist.

As the official distributor of Mebra Plastik Italia — a global leader in tubing and pneumatic hose manufacturing with over 50 years of experience — we are committed to delivering solutions that enhance your industrial performance.

Our expert team is ready to provide personalized consultations and detailed product information to help you make informed decisions. With the right pneumatic hoses, you can maximize system durability, maintain consistent performance, and achieve greater operational efficiency.

Trust in Mebra Plastik Italia’s decades of innovation and excellence, supported locally by PT. Bawalaksana Central Industrial.

Contact our expert today for personalized advice or a customized quote. Explore our full range of products and unlock the full potential of your pneumatic systems with confidence and reliability.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)