Polyurethane (PU) hose is a pneumatic hose that has elastic, strong and high flexibility characteristics. We have a wide range of PU hose options for various general to specific industrial applications such as oil and gas, ATEX and F&B industries.

In this article, the Bawalaksana.id team would like to fully describe the size of PU hoses for various industrial applications accompanied by detailed specifications:

- Minimum folding distance (minimum bending radius)

- Size of outer diameter (OD), inner diameter (ID) and thickness

- Characteristics and applications for each type of PU hose

- Recommended operating pressure (BAR)

- Available color options

We need to inform you that since the characteristics of each PU hose are very different for each type and type, we recommend clicking on each link we provide to learn the typology details of each PU hose.

That way, you can determine the right type of PU hose and size to suit the application in your industry.

Here is a complete list of PU hose sizes.

98 MB-Longlife® PU Hose

PU Hose (Flexible Linear Hose) 98 MB-Longlife® is the most popular and widely used Polyurethane hose type for general industrial applications. This type of PU hose has all the advantages for standard industrial applications with less complex environmental challenges.

The advantages of the 98 MB-Longlife® PU hose are as follows:

- Highly flexible and strong with a hardness of 52 Shore D

- Can be used in almost all industry standard low pressure pneumatic system applications

- Good dimensional stability and not easy to damage

- Very small bending radius

- Has good resistance to bending and abrasion

- Suitable for use on very fast moving devices or systems

- Has many color options for ease of application

The details of the 98 MB-Longlife® PU hose size are as follows:

| Part number | Inner diameter (ID) | Outer diameter (OD) | Wall thickness | Minimum bending radius | Operating pressure (23°C) | Standard colors |

|---|---|---|---|---|---|---|

| PU2X4 | 2 mm | 4 mm | 1 mm | 10 mm | 22 BAR | N A S R G T |

| PU2.3X4 | 2.3 mm | 4 mm | 0.85 mm | 15 mm | 17 BAR | N A T |

| PU2.5X4 | 2.5 mm | 4 mm | 0.75 mm | 15 mm | 15 BAR | N BT VT A S R G T |

| PU3X5 | 3 mm | 5 mm | 1 mm | 20 mm | 16 BAR | N A T |

| PU4X6 | 4 mm | 6 mm | 1 mm | 25 mm | 13 BAR | N BT VT A S BL R AR G T |

| PU5X8 | 5 mm | 8 mm | 1.5 mm | 30 mm | 15 BAR | N A R G T |

| PU5.5X8 | 5.5 mm | 8 mm | 1.25 mm | 40 mm | 12 BAR | N BT VT A BL R G T |

| PU6X8 | 5.7 mm | 8 mm | 1.15 mm | 40 mm | 11 BAR | N BT VT A S R G T |

| PU6.5X10 | 6.5 mm | 10 mm | 1.75 mm | 40 mm | 14 BAR | N A T |

| PU7X10 | 7 mm | 10 mm | 1.5 mm | 50 mm | 11 BAR | N A R G T |

| PU7.5X10 | 7.5 mm | 10 mm | 1.25 mm | 60 mm | 9 BAR | N BT VT A S R G T |

| PU8X10 | 7.7 mm | 10 mm | 1.15 mm | 65 mm | 8 BAR | N BT A S R G T |

| PU8X12 | 8 mm | 12 mm | 2 mm | 50 mm | 13 BAR | N BT A S R T |

| PU9X12 | 9 mm | 12 mm | 1.5 mm | 70 mm | 9 BAR | N BT VT A S R G T |

| PU10X14 | 10 mm | 14 mm | 2 mm | 70 mm | 11 BAR | N A T |

| PU11X14 | 11 mm | 14 mm | 1.5 mm | 100 mm | 8 BAR | N A R T |

| PU11X16 | 11 mm | 16 mm | 2.5 mm | 75 mm | 12 BAR | N A T |

| PU12X16 | 12 mm | 16 mm | 2 mm | 95 mm | 9 BAR | N A R T |

The color options available for the 98 MB-Longlife® PU hose are as follows:

- Black (N)

- Blue (A)

- Gray (S)

- Red (R)

- Yellow (G)

- White (T)

- Green (VT)

- Electric Blue (BT)

The 98 MB-Longlife® PU hose application can be used for:

- Industrial Automation

- Robotics

- Vacuum

- Machine Tools

PU 1185 High Flexibility Hose

PU 1185 Extraflex Hose is a highly flexible, soft, anti-folding, twist-resistant pneumatic hose with excellent elastic memory. It has good resistance to moisture, microbial attack and friction, and with a hardness level of 85 ShA.

Polyurethane 1185 Extraflex 85 ShA hose is the best pneumatic tubing for industrial robot applications and devices with high mobility.

The advantages of PU 1185 Extraflex hose are as follows:

- Twist-resistant, not easy to fold and can return to its original shape by itself

- Highly versatile and flexible, suitable for high moving robots applications

- Friction and abrasion resistant so it can be used for powder paint, industrial automation and machine tools.

- Resistant to moisture (hydrolysis resistance) and microbial attack making it safe for wet environments

- PU hose for hydroponics with economical price

The details of the PU 1185 Extraflex hose size are as follows:

| Part number | Inner diameter (ID) | Outer diameter (OD) | Wall thickness | Minimum bending radius | Operating pressure (23°C) | Standard colors |

|---|---|---|---|---|---|---|

| 185TE1.5X3 | 1.5 mm | 3 mm | 0.75 mm | 5 mm | 8 BAR | T |

| 185TE3.17X6.35 | 3.17 mm | 6.35 mm | 1.59 mm | 15 mm | 8 BAR | N T |

| 185TE5X9 | 5 mm | 9 mm | 2 mm | 20 mm | 7 BAR | N T |

| 185TE14X20 | 14 mm | 20 mm | 3 mm | 60 mm | 4 BAR | T |

| 185TE18X24 | 18 mm | 24 mm | 3 mm | 90 mm | 3 BAR | T |

The color options available for PU 1185 Extraflex hose are as follows:

- Black (N)

- White (T)

Extraflex PU 1185 hose applications can be used for:

- Industrial Automation

- Powders Paints

- Robotics

- Hydrolysis Resistance

- Machine Tools

Fabuthane® 54 PU Hose (FDA Approved)

Fabuthane® 54 PU Hose FDA Approved is the best food grade pneumatic tubing that we highly recommend for the F&B industry. It has a transparent color and a hardness level of 54 Shore D.

This PU hose can be used for both solid and liquid food contact with good abrasion resistance based on FCMs (Food Contact Materials).

The advantages of Fabuthane® 54 PU hose are as follows:

- Does not release plastic substances into food at levels harmful to human health (CE Reg. 1935/2004)

- Does not alter the composition, taste and odor of food to unacceptable levels (CE Reg. 1935/2004)

- Hose material is not food reactive (CE Reg. 10/2011)

- Resistant to abrasion, so it does not contaminate food or drinks (54 Shore D)

- Safe for food and drug products (FDA Title 21)

- Stabilized in light to prevent degradation of hose material due to UV exposure

- Has a minimum folding distance ranging from 15-75 mm

The details of the Fabuthane® 54 PU hose size are as follows:

| Part number | Inner diameter (ID) | Outer diameter (OD) | Wall thickness | Minimum bending radius | Operating pressure (23°C) |

|---|---|---|---|---|---|

| 54FBU2.5X4FA | 2.5 mm | 4 mm | 0.75 mm | 15 mm | 12 BAR |

| 54FBU2.7X4.3FA | 2.7 mm | 4.3 mm | 0.8 mm | 20 mm | 12 BAR |

| 54FBU4X6FA | 3.8 mm | 6 mm | 1.1 mm | 25 mm | 11 BAR |

| 54FBU5.5X8FA | 5.5 mm | 8 mm | 1.25 mm | 40 mm | 9 BAR |

| 54FBU7.5X10FA | 7.5 mm | 10 mm | 1.25 mm | 60 mm | 7 BAR |

| 54FBU8X12FA | 8 mm | 12 mm | 2 mm | 50 mm | 10 BAR |

| 54FBU9X12FA | 9 mm | 12 mm | 1.5 mm | 70 mm | 7 BAR |

| 54FBU11X16FA | 11 mm | 16 mm | 2.5 mm | 75 mm | 9 BAR |

Fabuthane® 54 PU hose applications can be used for:

- Industrial Automation

- Robotics

- Drinkable Water

- Vacuum

- Food Contact

- Machine Tools

- Hydrolysis Resistance

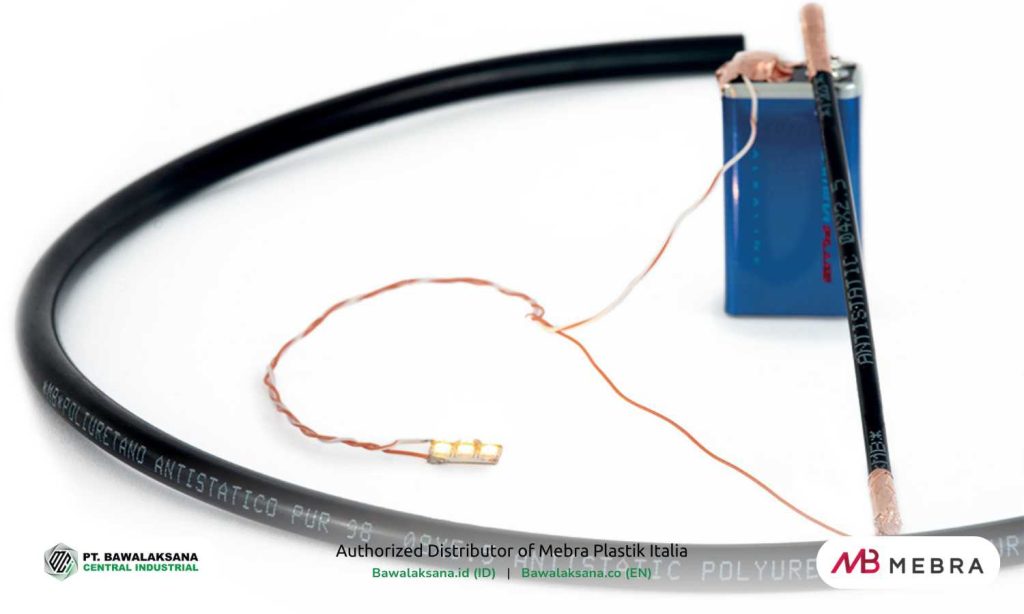

Antistatic Polyurethane 98 Tubing (ATEX Environment)

Antistatic PU 98 Tubing is a pneumatic hose specifically designed for applications in the ATEX Environment, cable carrier, powder paint and other sectors.

This Antistatic PU Tubing is for low pressure operation which is for ATEX environment, group 2, 2/3 category G&D, installation zone 1, 2 with surface electrical resistivity <= 10^6 Ohm according to ISO 8031:2009(E).

The advantages of the PU 98 Antistatic hose are as follows:

- Best choice for applications in ATEX environments, group 2, 2/3 G&D categories, installation zones 1, 2.

- The hose prevents the accumulation of electrostatic charges, making it safe for use in environments with a high risk of explosions or sparks, such as the oil, gas, methane and hydrogen processing industries.

- It has good abrasion resistance, so it can be used to spray powder paint, as well as as a cable carrier in rigs or manufacturing.

The details of the PU 98 Antistatic hose size are as follows:

| Part number | Inner diameter (ID) | Outer diameter (OD) | Wall thickness | Minimum bending radius | Operating pressure (23°C) |

|---|---|---|---|---|---|

| 98LA2.5X4 | 2.5 mm | 4 mm | 0.75 mm | 15 mm | 15 BAR |

| 98LA4X6 | 3.8 mm | 6 mm | 1.1 mm | 25 mm | 14 BAR |

| 98LA5X8 | 5 mm | 8 mm | 1.5 mm | 30 mm | 15 BAR |

| 98LA5.5X8 | 5.5 mm | 8 mm | 1.25 mm | 40 mm | 12 BAR |

| 98LA6.5X10 | 6.5 mm | 10 mm | 1.75 mm | 40 mm | 14 BAR |

| 98LA8X12 | 8 mm | 12 mm | 2 mm | 50 mm | 13 BAR |

The color options available for PU 98 Antistatic hose are as follows:

- Black (N)

Application of PU 98 Antistatic hose can be used for:

- Industrial Automation

- Electrical Resistance

- Cable Carrier Chain

- Machine Tools

- Powders Paints

- Robotics

- Vacuum

- ATEX

| Also Read: 11 Types of Heat Resistant Hose for Industry |

PU Hose Clear 1198 UV Resistance

Tubing PU Clear 1198 is a pneumatic hose designed with clear and transparent colors. This PU 1198 hose has good resistance to UV rays in all color choices so that it is not easily weathered due to sun exposure.

The advantages of PU Clear 1198 UV Resistance hose are as follows:

- UV and moisture resistant for all colors, so the hose is more durable and not easily damaged

- Included in the ether category 98 ShA with a hardness level of 52 Shore D

- Has good dimensional and abrasion resistance, while still having high flexibility

- Clear or clear color, the best choice for applications that require fluid observation or visual inspection

The details of the PU Clear 1198 UV Resistance hose size are as follows:

| Part number | Inner diameter (ID) | Outer diameter (OD) | Wall thickness | Minimum bending radius | Operating pressure (23°C) | Standard colors |

|---|---|---|---|---|---|---|

| 198TEA2.5X4 | 2.5 mm | 4 mm | 0.75 mm | 15 mm | 12 BAR | BT T AT |

| 198TEA4X6 | 4 mm | 6 mm | 1.1 mm | 25 mm | 11 BAR | N BT RT T AT |

| 198TEA5X8 | 5 mm | 8 mm | 1.5 mm | 30 mm | 12 BAR | BT T AT |

| 198TEA5.5X8 | 5.5 mm | 8 mm | 1.25 mm | 40 mm | 9 BAR | N BT T AT |

| 198TEA6.5X10 | 6.5 mm | 10 mm | 1.75 mm | 40 mm | 11 BAR | BT T |

| 198TEA7X10 | 7 mm | 10 mm | 1.5 mm | 50 mm | 9 BAR | N BT T B |

| 198TEA7.5X10 | 7.5 mm | 10 mm | 1.25 mm | 60 mm | 7 BAR | BT VT T AT |

| 198TEA8X12 | 8 mm | 12 mm | 2 mm | 50 mm | 10 BAR | BT RT T B AT |

| 198TEA9X12 | 9 mm | 12 mm | 1.5 mm | 70 mm | 7 BAR | BT T AT |

The color options available for PU Clear 1198 UV Resistance hose are as follows:

- Black (N)

- White (T)

- Navy (B)

- Electric Blue (BT)

- Bright Blue (AT)

- Terracotta (RT)

The application of PU Clear 1198 UV Resistance hose can be used for:

- Industrial Automation

- Robotics

- UV Resistance

- Vacuum

- Cable Carrier Chain

- Machine Tools

- Hydrolysis Resistance

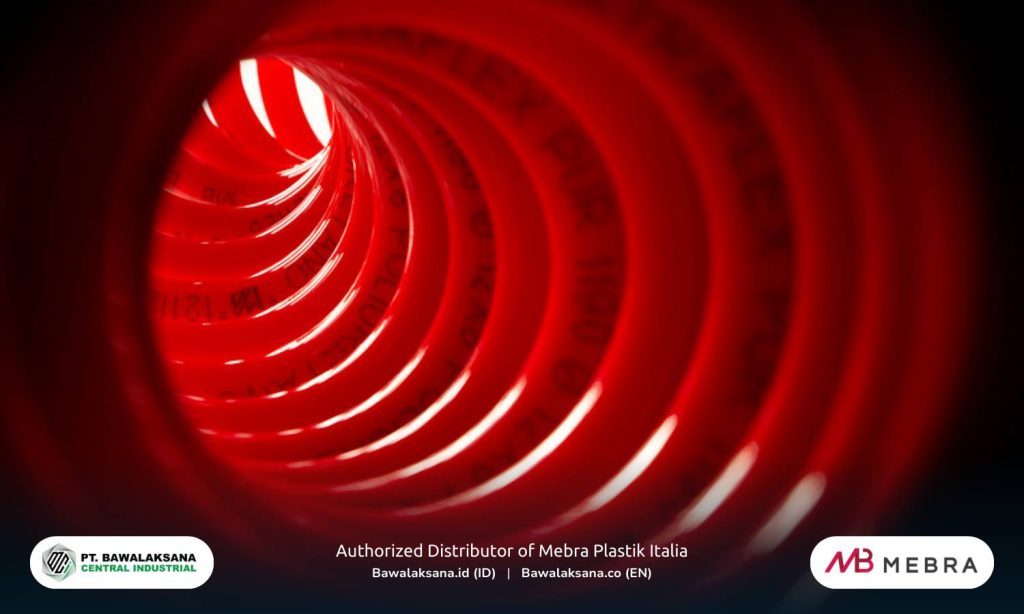

PU Spiral Hose 1190 Extraflex High Flexibility

Extraflex PU Spiral 1190 Tubing is a spiral pneumatic hose with the characteristics of high flexibility and strong elastic memory (can maintain its original shape)…

The advantages of Extraflex Spiral 1190 PU tubing are as follows:

- Has good resistance to moisture (hydrolysis resistance) and microbial attack

- Abrasion resistant and has good elastic memory to maintain its original shape

- Good resistance to repeated over-extension, twisting and tugging

- Can be used as a good cable sleeve material for high mobility applications

The details of the size of the PU Spiral 1190 Extraflex tubing are as follows:

| Part number | Inner diameter (ID) | Outer diameter (OD) | Wall thickness | Standard colors | Material length | Working length | Retracted length | Turns N | A Tale | Tale B | Winding Ø | Outer Ø |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S190TE2.5X4X3C | 2.5 mm | 4 mm | 0.75 mm | A | 3 m | 2.5 m | 269 mm | 64 N | 100 mm | 100 mm | 10 mm | 18 mm |

| S190TE2.5X4X4C | 2.5 mm | 4 mm | 0.75 mm | A | 4 m | 3 m | 214 mm | 51 N | 100 mm | 100 mm | 20 mm | 28 mm |

| S190TE4X6X2C | 3.8 mm | 6 mm | 1.1 mm | A | 2 m | 1.5 m | 138 mm | 22 N | 100 mm | 100 mm | 20 mm | 32 mm |

| S190TE4X6X4C | 3.8 mm | 6 mm | 1.1 mm | N A | 4 m | 3 m | 296 mm | 47 N | 100 mm | 100 mm | 20 mm | 32 mm |

| S190TE5.5X8X2.5C | 5.5 mm | 8 mm | 1.25 mm | A | 2.5 m | 2 m | 151 mm | 18 N | 120 mm | 500 mm | 25 mm | 41 mm |

| S190TE5.5X8X5C | 5.5 mm | 8 mm | 1.25 mm | N A | 5 m | 4 m | 362 mm | 43 N | 120 mm | 500 mm | 25 mm | 41 mm |

| S190TE5.5X8X7.5C | 5.5 mm | 8 mm | 1.25 mm | A T | 7.5 m | 6 m | 564 mm | 67 N | 120 mm | 500 mm | 25 mm | 41 mm |

| S190TE5.5X8X10C | 5.5 mm | 8 mm | 1.25 mm | A | 10 m | 7.5 m | 766 mm | 91 N | 120 mm | 500 mm | 25 mm | 41 mm |

| S190TE5.5X8X12.5C | 5.5 mm | 8 mm | 1.25 mm | N A | 12.5 m | 9.5 m | 976 mm | 116 N | 120 mm | 500 mm | 25 mm | 41 mm |

| S190TE6.5X10X2.5C | 6.5 mm | 10 mm | 1.75 mm | A | 2.5 m | 2 m | 126 mm | 12 N | 120 mm | 500 mm | 40 mm | 60 mm |

| S190TE6.5X10X5C | 6.5 mm | 10 mm | 1.75 mm | A | 5 m | 4 m | 294 mm | 28 N | 120 mm | 500 mm | 40 mm | 60 mm |

| S190TE6.5X10X7.5C | 6.5 mm | 10 mm | 1.75 mm | A | 7.5 m | 6 m | 463 mm | 44 N | 120 mm | 500 mm | 40 mm | 60 mm |

| S190TE6.5X10X10C | 6.5 mm | 10 mm | 1.75 mm | N A | 10 m | 7.5 m | 631 mm | 60 N | 120 mm | 500 mm | 40 mm | 60 mm |

| S190TE6.5X10X12.5C | 6.5 mm | 10 mm | 1.75 mm | A | 12.5 m | 9.5 m | 800 mm | 76 N | 120 mm | 500 mm | 40 mm | 60 mm |

| S190TE8X12X2.5C | 8 mm | 12 mm | 2 mm | A | 2.5 m | 2 m | 126 mm | 10 N | 120 mm | 500 mm | 50 mm | 74 mm |

| S190TE8X12X5C | 8 mm | 12 mm | 2 mm | N A | 5 m | 4 m | 290 mm | 23 N | 120 mm | 500 mm | 50 mm | 74 mm |

| S190TE8X12X7.5C | 8 mm | 12 mm | 2 mm | A | 7.5 m | 6 m | 454 mm | 36 N | 120 mm | 500 mm | 50 mm | 74 mm |

| S190TE8X12X10C | 8 mm | 12 mm | 2 mm | N A | 10 m | 7.5 m | 618 mm | 49 N | 120 mm | 500 mm | 50 mm | 74 mm |

| S190TE8X12X12.5C | 8 mm | 12 mm | 2 mm | A | 12.5 m | 9.5 m | 770 mm | 61 N | 120 mm | 500 mm | 50 mm | 74 mm |

| S190TE8X12X15C | 8 mm | 12 mm | 2 mm | A | 15 m | 11.5 m | 934 mm | 74 N | 120 mm | 500 mm | 50 mm | 74 mm |

The color options available for Extraflex Spiral 1190 PU tubing are as follows:

- Blue (A)

- Black (N)

Applications Extraflex Spiral 1190 PU tubing can be used for:

- Industrial Automation

- Hydrolysis Resistance

- Robotics

- Cable Carrier Chain

- Machine Tools

PU 1190 WR hose

PU 1190 WR Hose is the best product for drag chain (cable chain) or energy chain applications in highly critical sectors such as the oil and gas industry for drilling on rigs and modern manufacturing using industrial robots.

The advantages of PU 1190 WR hose are as follows:

- Self-Lubricating (SL series) is made with a special formulation so that it has 3x better abrasion resistance than Extraflex Spiral 1190 PU hose.

- Abrasion resistance, as well as exceptional flexibility, so it is not easily damaged by repeated elongation, twisting and tugging.

- Can be used as a cable protector used in drag chains or for low pressure pneumatic supplies.

- A great choice for use in energy chains or drag chains.

- Good resistance to moisture and microbial attack.

The details of the PU 1190 WR hose size are as follows:

| Part number | Inner diameter (ID) | Outer diameter (OD) | Wall thickness | Minimum bending radius | Operating pressure (23°C) |

|---|---|---|---|---|---|

| 190WR4X6 | 3.8 mm | 6 mm | 1.1 mm | 25 mm | 11 BAR |

| 190WR5.5X8 | 5.5 mm | 8 mm | 1.25 mm | 40 mm | 9 BAR |

PU 1190 WR hose applications can be used for:

- Industrial Automation

- Robotics

- Cable Carrier Chain

- Hydrolysis Resistance

- Machine Tools

Get Complete Industrial Tubing Solutions of the Best Quality from Trusted Distributors

This is a complete list of PU hose sizes that we can note in this article. And actually, we still have a number of other PU (Polyurethane) hose products in our product catalog for various specific industry sectors.

It is important to note that each of the PU hoses we mentioned above has specific specifications for specific applications. Therefore, we would like to emphasize that you need to customize the right hose size and technical specifications for the application in your industrial sector.

This is important as it contributes to the durability and service life of the hose. Choosing the right type of hose for a specific application can prevent the hose from being easily worn, damaged or broken.

We have written a complete guide to How to Choose the Right Pneumatic Hose for Industrial Automation System in a previous article.

PT. Bawalaksana Central Industrial is the official and trusted distributor for Mebra Plastik Italiaa manufacturer specializing in industrial tubing and pneumatic hoses.

We can provide a wide range of industrial tubing for critical sectors, from Polyurethane (PU), Polyethylene (PE), Polyamide (PA) including Nylon hoses and also from the Fluoropolymer family including PTFE (Teflon) hoses for applications in extreme environments.

Get complete information regarding catalogs and datasheets for all industrial tubing from Mebra Plastik Italia by contacting our Sales Engineer team by clicking the Consultation button below.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)

![Problems with 3 Phase Contactors and How to Solve Them [Practical & Effective]](https://bawalaksana.co/wp-content/uploads/2025/07/Masalah-Pada-Kontaktor-Motor-3-Phase-dan-Cara-Mengatasinya-Bawalaksana-ID-1080x675.jpg)