Electronics manufacturing and computer device production are significantly dependent on pneumatic systems. The high-quality fabrication of the minute components in electronic devices necessitates a clean and sterile manufacturing environment.

Even the most minute dust particles and contaminants can adversely affect the semiconductor manufacturing process if an adequate air filtration system is not in place.

Therefore, cleanrooms powered by pneumatic systems are essential. They ensure the effective production of semiconductors from micro to nanometer sizes.

In this article, Bawalaksana Central Industrial will explore the functions and applications of pneumatic technology in electronics manufacturing, semiconductor production, and computer device fabrication.

Cleanroom for Electronic Component Assembly

As previously indicated, electronic products are sophisticated digital devices vulnerable to damage. Production failures may arise in electronics manufacturing for many reasons. One of the most prevalent causes is an unclean environment that harbors contaminants such as dust and dirt.

Pneumatic systems and devices, despite their inherent simplicity, provide an optimal solution to address these challenges. The functions of pneumatic systems in Cleanrooms encompass the following:

- Filtering air to eliminate dust, dirt, and other contaminants.

- Controlling doors to ensure secure closure and locking mechanisms.

- Regulating airflow and air pressure within the Cleanroom environment.

Cleanrooms are essential environments for fabricating semiconductors with micro- to nanometer-level precision. These facilities also play a crucial role in assembling electronic components and various computational devices.

Cleanrooms must be consistently and continuously maintained to facilitate a seamless production process for electronic components and devices.

Pneumatic systems are integral to maintaining the cleanliness of Cleanrooms. Although they are often perceived as straightforward, these systems are essential in ensuring the production quality of computer devices and semiconductors.

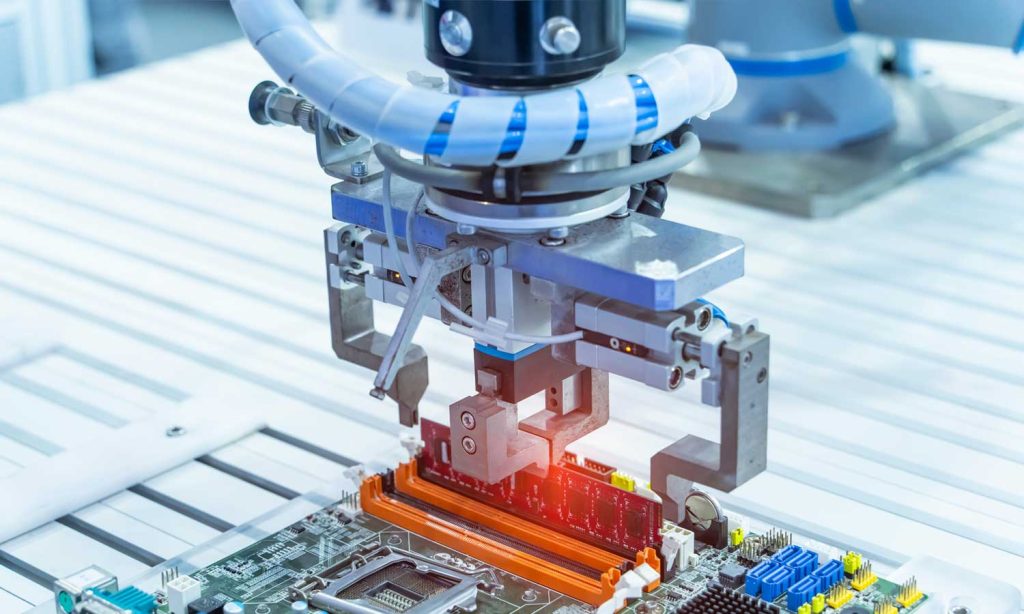

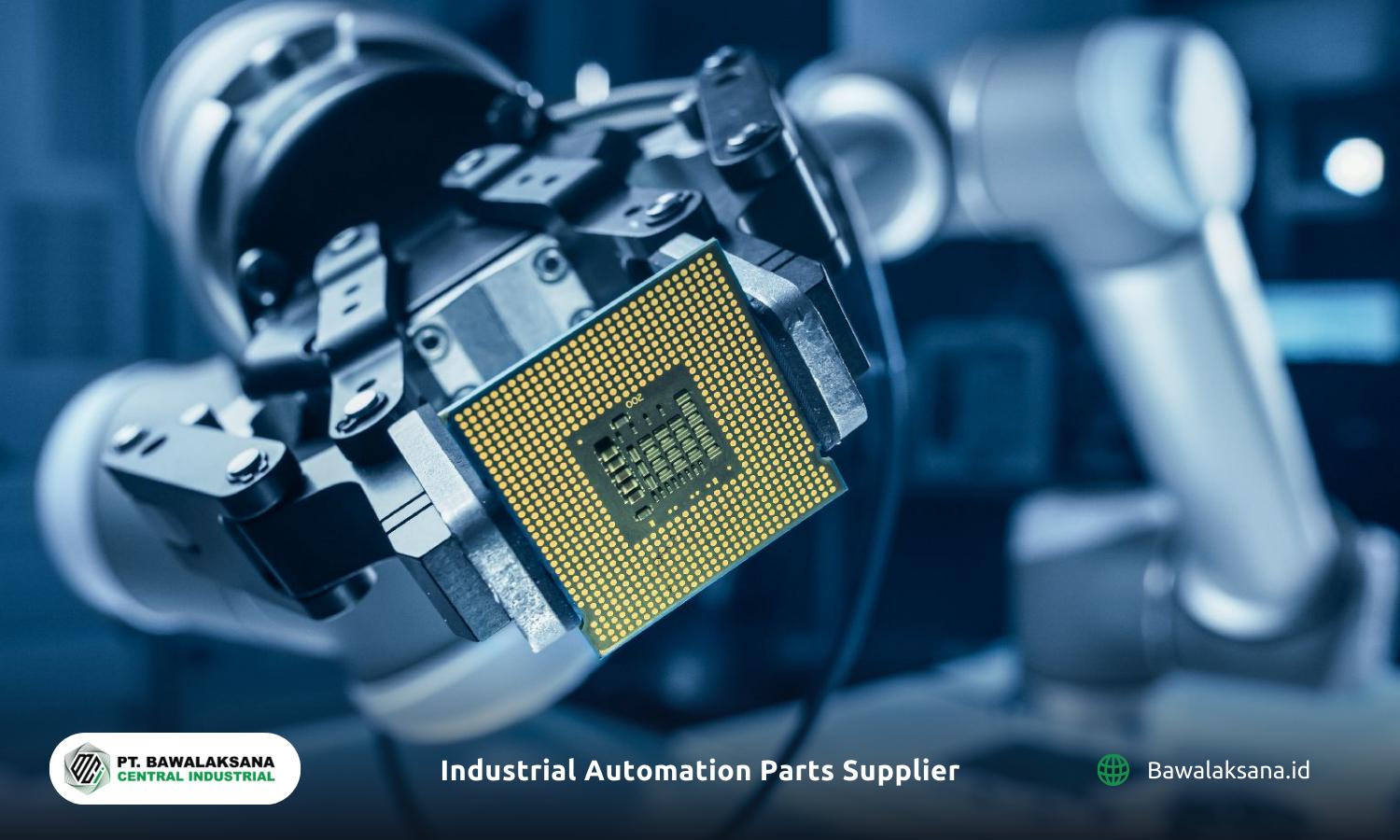

Handling and Assembly

Pneumatic systems ensure the cleanliness of cleanroom environments and are employed in various production lines, including handling and assembly processes. A pertinent example is the utilization of pick-and-place robots equipped with pneumatic vacuum systems. These robots are designed to lift and accurately position small components onto printed circuit boards (PCBs).

Furthermore, automated assembly processes are employed for component placement and soldering. In these instances, pneumatic cylinders are frequently integrated into robotic arms. Once the soldering points have been identified, the pneumatic cylinder can rapidly and precisely insert and solder electronic components.

Integrated additional technologies, such as Programmable Logic Controllers (PLC), motors, and sensors, facilitate such advanced functionalities, enhancing operational efficiency and precision in manufacturing settings.

Pneumatic Conveyor System

Manufacturing electronics and computer devices entails handling many small components distributed throughout the production line. Before entering the assembly and installation phases, it is imperative that these components be sorted and transferred with speed and precision. This practice ensures accurate placement and mitigates the risk of component mix-ups.

Electronics manufacturers require an advanced conveyor system capable of effectively controlling, organizing, and systematically transferring components. Pneumatic conveyor systems are an ideal solution for addressing this requirement.

Pneumatic systems are designed to execute this task both efficiently and continuously. These pneumatic-powered conveyors facilitate the secure transfer of small electronic components between various workstations along the production line. A pneumatic conveyor system can efficiently conduct a fast and safe transfer process.

Testing and Inspection

In electronics manufacturing, product testing plays a crucial role in ensuring the reliability and quality of electronic devices. Automated testing procedures are frequently utilized to verify the functionality of specific circuits and components within a product.

This process confirms that the product operates as intended and guarantees the integrity of the installed parts.

Pneumatic cylinders are often employed to enhance the efficiency and accuracy of testing and inspection. These devices apply controlled and repetitive pressure during testing, facilitating swift evaluations directly on the production line. This methodology significantly contributes to maintaining high product quality standards throughout the assembly process.

Packaging and Sealing

In the final stage of the electronics manufacturing process, pneumatic devices play a crucial role in sealing products within protective or antistatic packaging. These pneumatic cylinders offer precise control and adjustable speed, making them an effective solution for ensuring that packaging is sealed tightly and securely.

The role of pneumatic technology extends beyond sealing; it is also instrumental in preparing cartons and packaging materials, filling them with finished products, and ensuring the final packaging is securely closed.

Pneumatic technology is crucial in various industries, demonstrating its versatility and effectiveness. In electronics manufacturing, for instance, pneumatic systems transport components efficiently on assembly lines, ensuring precise placement and reducing the risk of damage.

This technology is vital for cleanroom operations in the semiconductor production sector, where it aids in the safe handling of delicate wafers and minimizes contamination risks.

Additionally, in developing computer devices, pneumatic systems facilitate the assembly and testing processes by providing the necessary force and control, enhancing productivity while maintaining high-quality standards. This multifaceted application of pneumatic technology underscores its significance in driving innovation and efficiency across these critical fields.

High-Quality Pneumatic System Components for Electronics Manufacturing

Pneumatic systems are integral to the production processes within the electronics manufacturing industry. The selection of high-quality components is critical to achieving optimal and consistent performance in production operations.

Key Benefits of Pneumatic Systems in Electronics Manufacturing

Implementing pneumatic systems in this sector offers several advantages, including:

- Pneumatic technology’s adaptability and ease of integration into various applications make companies feel innovative and forward-thinking.

- Clean and Hygienic Environment: These systems are well-suited for environments that require stringent cleanliness standards, minimizing the risk of contamination.

- Control over Speed and Force: Pneumatic systems allow for straightforward adjustments in speed and force, catering to specific operational requirements.

- Precision and Reliability: They provide accurate and dependable movement, essential for maintaining consistency throughout the production cycle.

- Enhanced Efficiency and Speed: By utilizing pneumatic systems, companies can improve production efficiency and accelerate processes, making them a valuable asset for businesses aiming to scale economically and boost profitability.

PT. Bawalaksana Central Industrial is the official distributor for Metal Work Pneumatic and Mebra Plastik Italia. We supply high-quality, advanced pneumatic devices to offer comprehensive solutions tailored to your manufacturing requirements.

Metal Work Pneumatic has established itself as a leader in pneumatic automation systems, boasting over 50 years of industry experience. It is internationally recognized for its reliability and superior quality and provides extensive pneumatic solutions across various critical sectors.

In parallel, Mebra Plastik Italia specializes in producing pneumatic and industrial hoses. Mebra’s industrial tubing products are distinguished by their exceptional quality and detailed specifications, serving a diverse array of industries.

Unlike many competitors, Metal Work Pneumatic and Mebra Plastik Italia deliver highly detailed product specifications, enabling you to integrate their products seamlessly into your systems confidently.

With extensive professional experience across diverse industrial sectors and collaborative partnerships in multiple countries throughout Asia and Europe, we offer precise and practical solutions to enhance your company’s productivity.

If you are considering implementing a modern and advanced pneumatic system for your enterprise, you have arrived at the best destination. Bawalaksana Central Industrial is your ideal partner for integrating new pneumatic technologies or maintaining industrial automation systems.

We invite you to consult with our engineering team today by selecting the Free Consultation button below.

Featured image by Shutterstock.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)