Pneumatic fittings are connecting components (connectors) that function to create a safe connection from leaks in compressed air systems (pneumatic systems).

This component is also known as Pneumatic Connector which will connect pneumatic hoses, cylinders, valves, FRL and other components in the pneumatic system. Pneumatic connectors are vital, as they serve to make it easier for the engineer team to design and customize air ducts in pneumatic systems.

The following are among the common examples of the benefits of pneumatic connections:

- Make it easy to disassemble components when maintaining or replacing devices

- Make it easier for engineers to add new technologies to improve system productivity.

- Reduce the air flow rate to certain components of the pneumatic system

- Designing air ducts for complex applications

- Increase system mobility for cylinder movement or pneumatic system connected devices

There is no doubt that the use of the right pneumatic fitting is the main foundation in maintaining system performance and efficiency at the most optimal level.

Conversely, improper implementation of pneumatic fittings contributes to decreased productivity and causes the system to experience frequent problems.

In this article, the Bawalaksana.id team will discuss in full what pneumatic fittings are, their types and functions for automation systems in industry.

What are Pneumatic Fittings and Their Functions?

Pneumatic fittings are components used to connect pneumatic hoses, cylinders, valves, FRLs and other components in compressed air systems.

The functions of pneumatic fittings include the following:

- Ensure each connection of the compressed air line is secure from leaks.

- Facilitate the process of loading and unloading pneumatic components, either for maintenance or adding tools.

- Makes it easy to connect various types of air ducts that have differences in size, material and shape.

- Facilitate the distribution of compressed air according to system needs.

- Increased air duct flexibility for applications requiring high mobility.

We need to inform you that pneumatic connectors have several types that are tailored to the hose material, pipe, operating pressure and industrial sector.

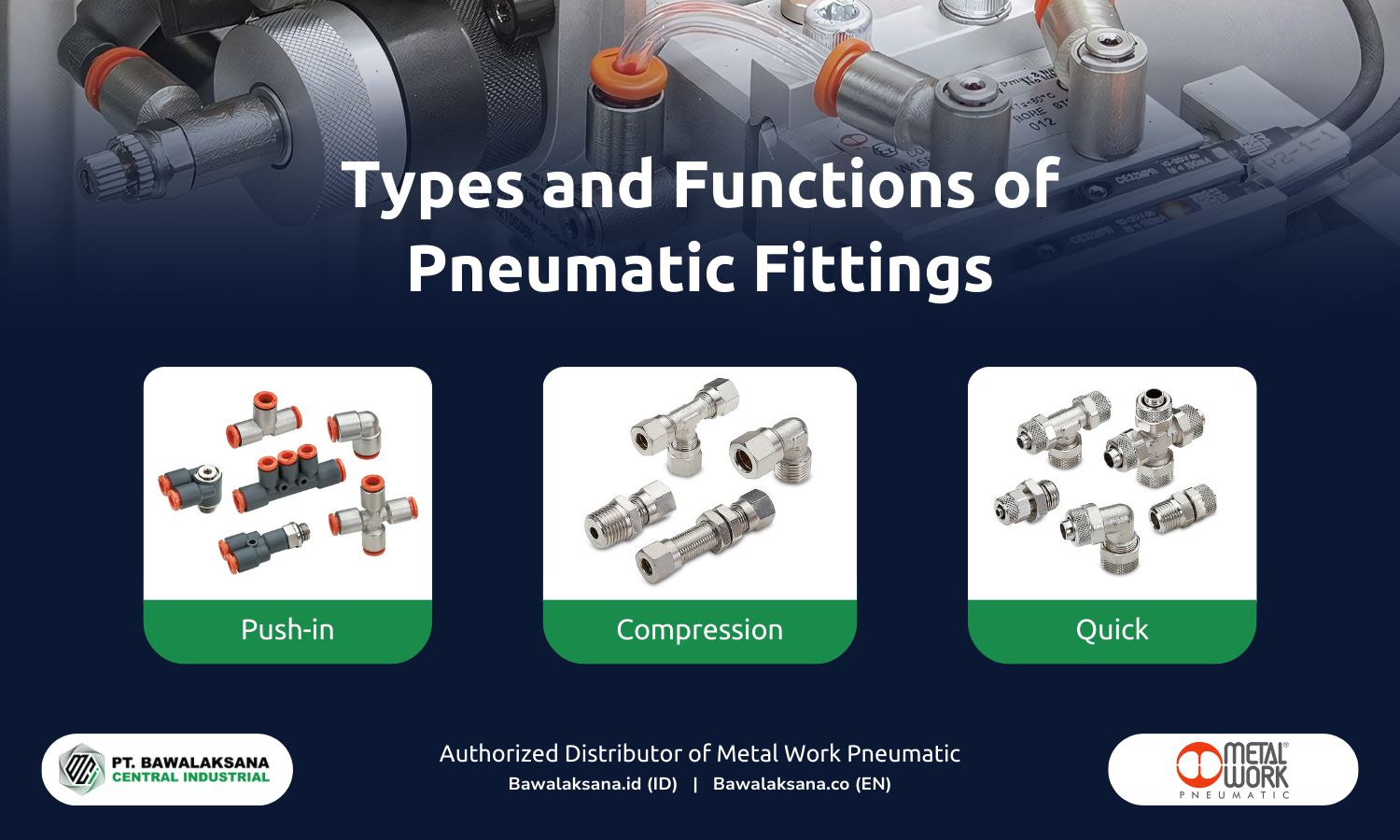

The types of pneumatic connectors at least include some types as follows:

- Push-in

- Standard (threaded)

- Compression

- Quick

- Plug-in (push-to-connect)

- And others

The materials of the fittings are also quite diverse, generally using 3 types of materials as follows:

- Technopolymer (plastic)

- Brass (white/yellow)

- Stainless steel

Please note, that each type of pneumatic connector has different compatibility and performance characteristics.

However, what must be realized is that with the many choices of pneumatic fittings available, this requires a team of engineers in the industry to be selective in making choices.

In addition, it is also necessary to ensure that the fittings used are not only suitable in terms of specifications, but also in terms of regulations that apply in your industry.

It is intended that the fittings used are not easily damaged resulting in disruption to the pneumatic system and productivity on the factory floor.

In fact, if the material used is not compatible with the application, it can contaminate the production process, reducing its quality.

Next, let’s discuss the types of pneumatic connections based on the shape and type of connector.

Types of Pneumatic Fittings Based on Their Shape

Basically, the types of pneumatic connections (pneumatic connectors) are very diverse and vary greatly in number, depending on the manufacturer or vendor who makes them.

The fitting products for each vendor also have their own advantages. Therefore, the most important thing to note is that the type and specifications chosen are suitable for the application in your company.

The following are among the most common types of pneumatic fittings used in industry:

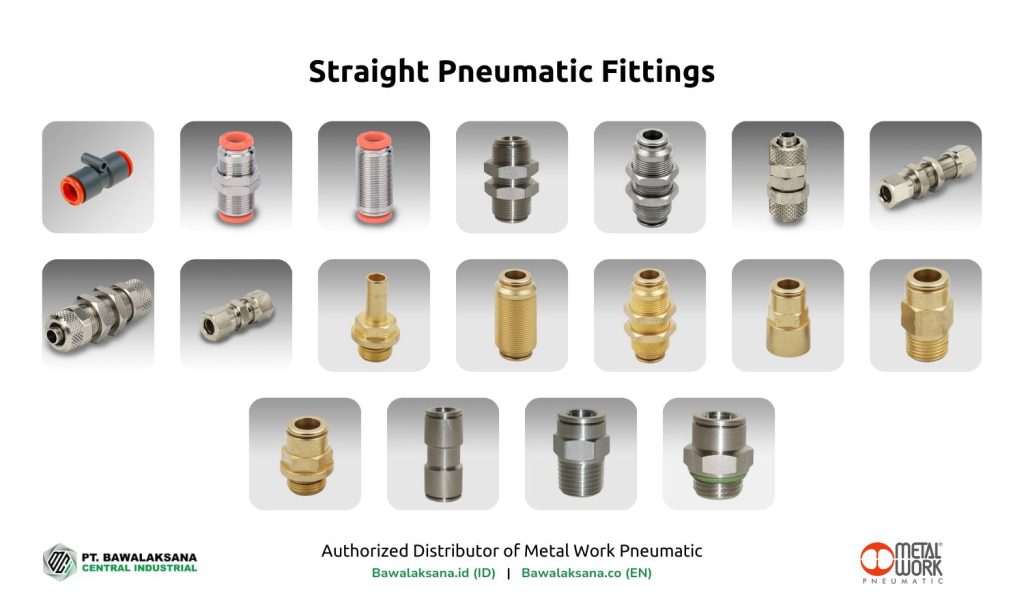

Straight

Straight pneumatic fittings or straight connectors are the most basic type and are widely used in pneumatic lines. Its main function is to connect two sections of hose that have the same size in a straight line or connect them with moving components.

Straight fitting applications include:

- Extend the pneumatic hose line at the same size.

- Connecting hoses to other components such as actuators and solenoid valves.

- Helps to connect polymer (plastic) hoses to metal conduits or vice versa.

- Reconnect the damaged hose by cutting off the unused part and reconnecting it.

- Inserting joints in distribution lines such as in pneumatic panels or airtight dashboards.

Connection types available for straight fittings include:

- Push-in

- Quick

- Standard

- Compression

The materials used for straight fittings consist of:

- Technopolymer (plastic)

- White or yellow brass

- Stainless steel

When selecting straight type fittings, it is necessary to consider environmental factors, working pressure, operating temperature and connection type compatible with hose or pipe material.

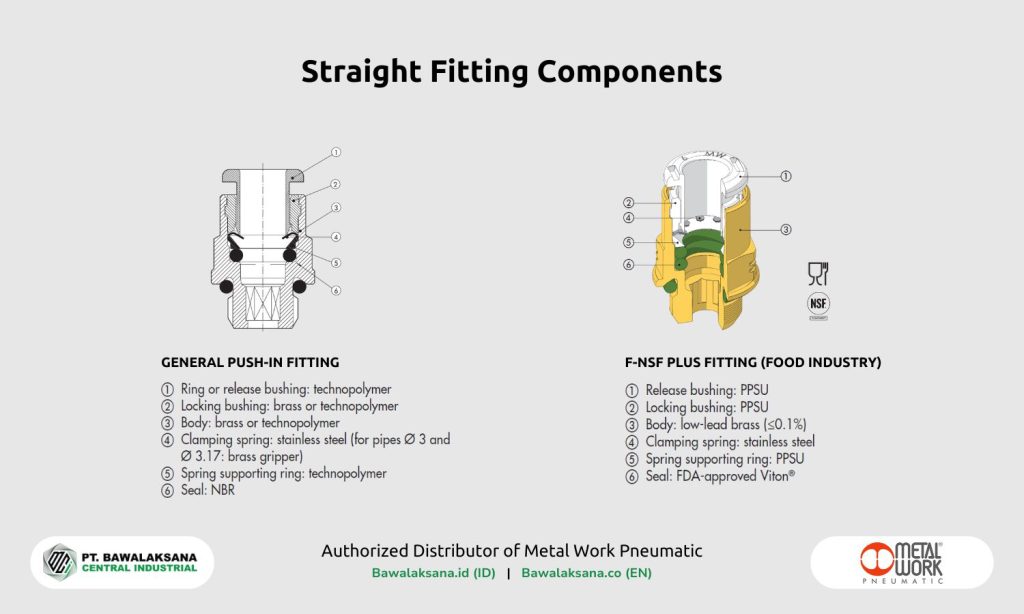

As general information, that the highest quality pneumatic connectors can offer various important advantages to improve operating standards in the industry, such as:

- It has a fine clamping spring that serves to hold the hose firmly without damaging or injuring it.

- Equipped with O-rings to promote a secure and leak-free connection. This feature is important as it can improve the thread seal to beveled, rough and slightly convex surfaces. Fittings with this feature no longer require sealants.

- It can be used thousands of times, without even needing a sealant of any material. That way, the lines of your pneumatic system will be clear of sealant contamination that may come off every time the fitting is turned.

- Especially for the F&B industry, you can choose the NSF/ANSI series which can be used for applications that experience frequent liquid and food contact.

| Also Read: Food Grade and Heat Resistant Pneumatic Fitting Recommendations |

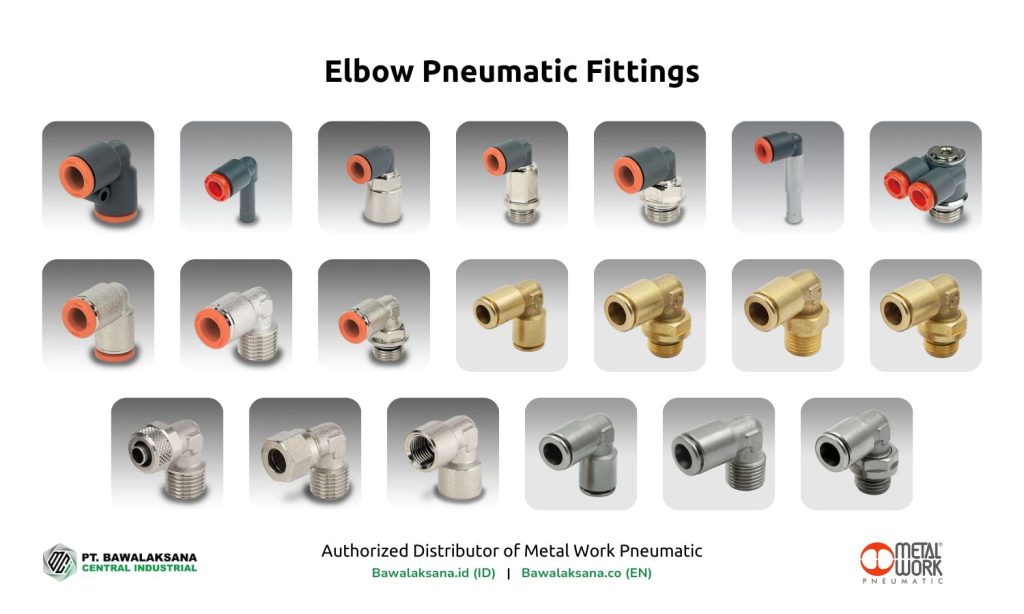

Elbow

Pneumatic elbow fittings function to make turns in the air flow and direct it to pass through obstacles or obstacles. This type of fitting is essential for optimizing the layout of the air path in a pneumatic system.

In some vendors, you can find elbows forming a right angle (90°) or with other angles.

Applications of elbow fittings include:

- Making turns in the air path of a pneumatic system in a confined space.

- Connect the hose to other components such as actuators and solenoid valves in a position perpendicular (90°) to the hose.

- Helps to connect polymer (plastic) hoses to metal conduits.

- Directing airflow to bypass obstacles or obstructions.

- Easy management of hoses and air distribution lines.

Connection types available for elbow fittings include:

- Push-in

- Quick

- Standard

- Compression

- Plug-in (push-to-connect)

The materials used for elbow fittings consist of:

- Technopolymer (plastic)

- White or yellow brass

- Stainless steel

Elbow type fittings are available in various connector types, sizes and configurations. Even so, we recommend using it wisely so that the airflow rate of the pneumatic system remains optimal.

Among the types of elbows that are worth mentioning are swivel fittings that can rotate to follow the displacement of the hose.

These advantages provide flexibility in installation and flexibility, so that it can follow the mobility of pneumatic cylinders that move in rotation.

In this article we will also discuss swivel fittings in full in the next section.

Tee (T)

Tee (T) pneumatic fittings function to divide or combine air flow in a pneumatic system. Tee fittings have three conduit holes that form a branch like the letter “T” and can provide a wide variety of connections in one component.

T fitting applications include:

- Divides the airflow in a pneumatic system from one source to two different paths.

- Combines airflow from two sources into one unidirectional path.

- Used to create tapping points for installing flowmeters, pressure gauges or other pneumatic components.

- Ease in air path adjustment and pneumatic system modification.

In general, T-type fittings have 3 options, such as:

- Equal: Each channel has the same size.

- Reducing: One of the ducts has a smaller diameter size, used to connect to air lines of different sizes.

- Branch: One of the air paths points sideways like a branch, while the other is in a straight/aligned position.

Connection types available for T fittings include:

- Push-in

- Quick

- Standard

- Compression

- Plug-in (push-to-connect)

The materials used for T fittings consist of:

- Technopolymer

- White or yellow brass

- Stainless steel

T-type fittings are available in a variety of connector types, materials, sizes and configurations. Therefore, proper selection according to the application in the industry contributes to the overall productivity and efficiency of the pneumatic system.

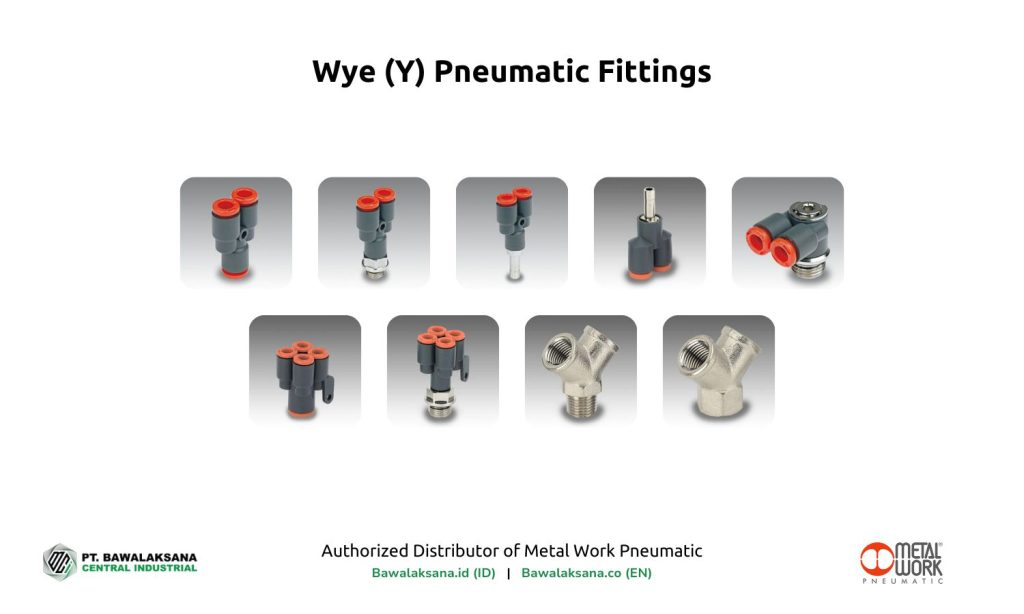

Wye (Y)

Wye (Y) pneumatic fittings have the same function as T fittings, which is to divide or combine flow in the air path of a pneumatic system.

The difference is that the branching for Y fittings is more sloping or does not form a 90° angle. in full. This is very important as it reduces turbulence in the pneumatic line to prevent pressure drop.

However, this advantage does not apply to parallel or dual branch Y fittings, as they have a more complex design.

Y fitting applications include:

- Divides the airflow in a pneumatic system from one source to two different paths, but with lower turbulence than a T fitting.

- Combines airflow from two sources into one unidirectional path.

- Used to produce 2 to 4 branching paths with smoother airflow (dual branch version).

- Ease in air path adjustment and pneumatic system modification.

In general, Y-type fittings have several options, such as:

- Equal: Each channel has the same size.

- Reducing: One of the ducts has a smaller diameter size, used to connect to air lines of different sizes.

- Parallel: A combination of elbow and wye (Y), the shaft consists of one line, while the elbow forms a branch.

- Dual Branch: A combination of 2Y fittings, the shaft consists of one line, then forms 4 branches.

- Y90°: The branching forms a perfect Y curve, resulting in minimal air turbulence.

Connection types available for Y fittings include:

- Push-in

- Standard

- Plug-in (push-to-connect)

The materials used for Y fittings consist of:

- Technopolymer

- White brass

Y fitting types have relatively few options than elbow and tee types. Similarly, the materials used are only available in 2 types, plastic and white brass.

Apart from that, each fitting vendor can offer options and advantages that vary with other vendors.

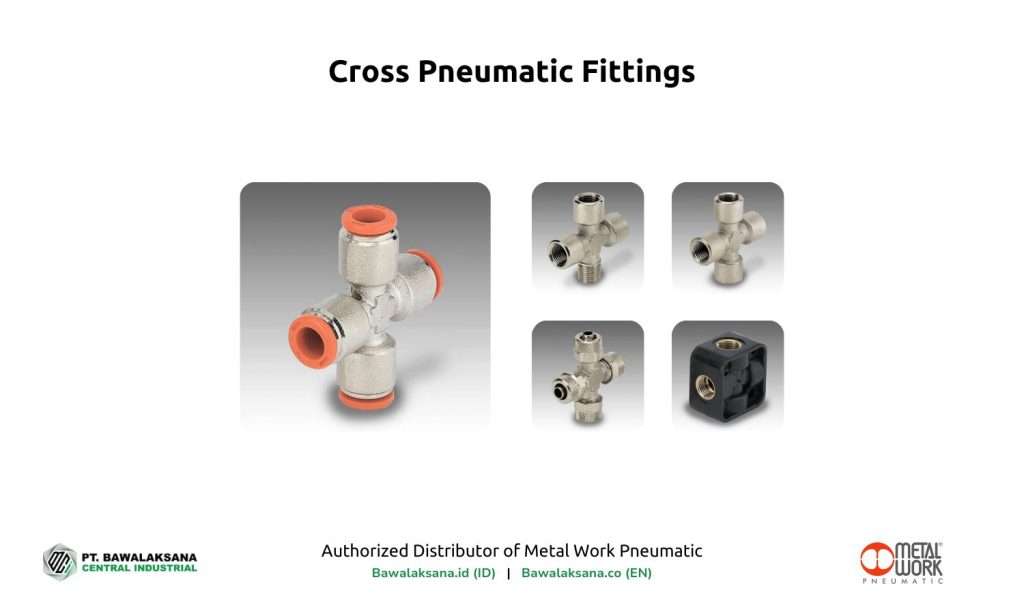

Cross (X)

Cross (X) pneumatic fittings or often called four-way fittings have four open airways and are perpendicular / crossed.

The function of this cross fitting is to distribute pressurized airflow in three directions at once from one source. As well as to connect several vital components in the pneumatic system.

Cross fitting applications include:

- Divides the airflow in a pneumatic system from a single source to three different paths in a crosswise manner, allowing four-way connections in a single fitting.

- Eases the layout of complex pneumatic systems and connects several vital components.

- Ease in air path adjustment and pneumatic system modification

Connection types available for cross fitting include:

- Push-in

- Standard

- Compression

The material for cross fitting uses:

- Technopolymer

- White brass

Cross fittings offer convenience in the distribution of air paths, but they have some disadvantages, such as:

- It has more significant turbulence compared to Y or T fitting.

- Prone to breakage, it is recommended to choose a cross fitting made of brass or technopolymer with a sturdy design.

- Cross fittings are often larger in size and less flexible in terms of shape, hence rarely used for applications in confined spaces.

Although this four way fitting has some drawbacks, it remains an important part of pneumatic systems in some applications.

And actually, you can also use T or Y connectors in combination to replace cross fittings, if you want to get better flexibility with lower turbulence.

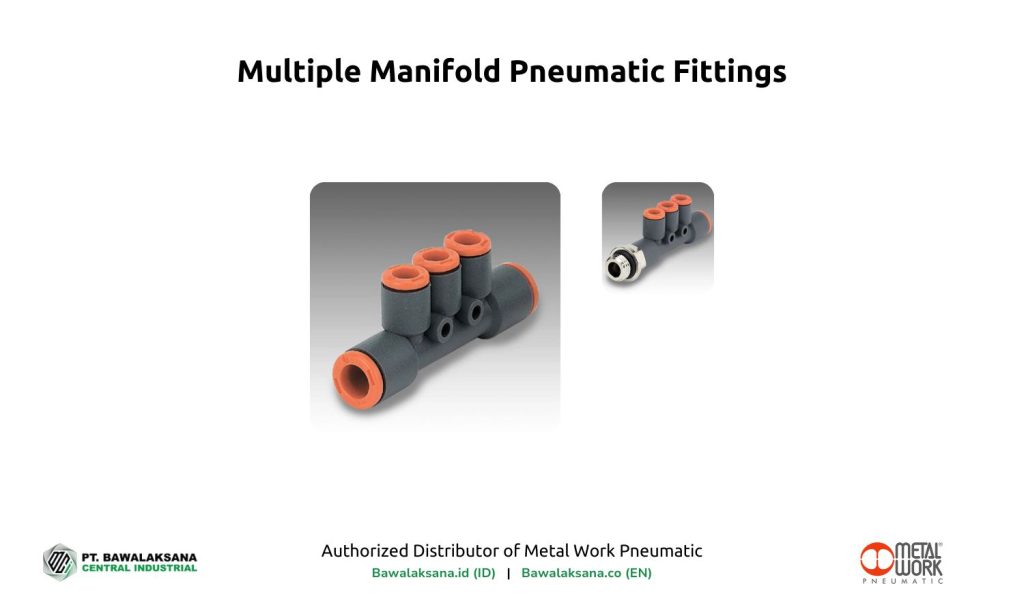

Multiple Manifolds

Multiple manifold fittings serve to divide the airflow from one source into several branches (up to 4 air paths).

Although functionally similar to the four-way fitting, the most striking difference is the formation. Multiple manifolds have one parallel air path (minimal turbulence), while the other three branch off to the side like a T fitting.

Although quite rarely used, multiple manifolds are one type of fitting that is very much needed, especially for complex pneumatic circuits.

Connection types available for manifold fittings include:

- Push-in

- Standard

The material for manifold fittings uses:

- Technopolymer

Note that the use of multiple manifold fittings is highly dependent on the design of the pneumatic system, airflow requirements and the complexity of the industrial application.

This type of fitting is needed when a single source of compressed air needs to be supplied to several pneumatic actuators or solenoid valves.

This method can also reduce the need for many pneumatic fittings and hoses, especially for applications in very limited spaces.

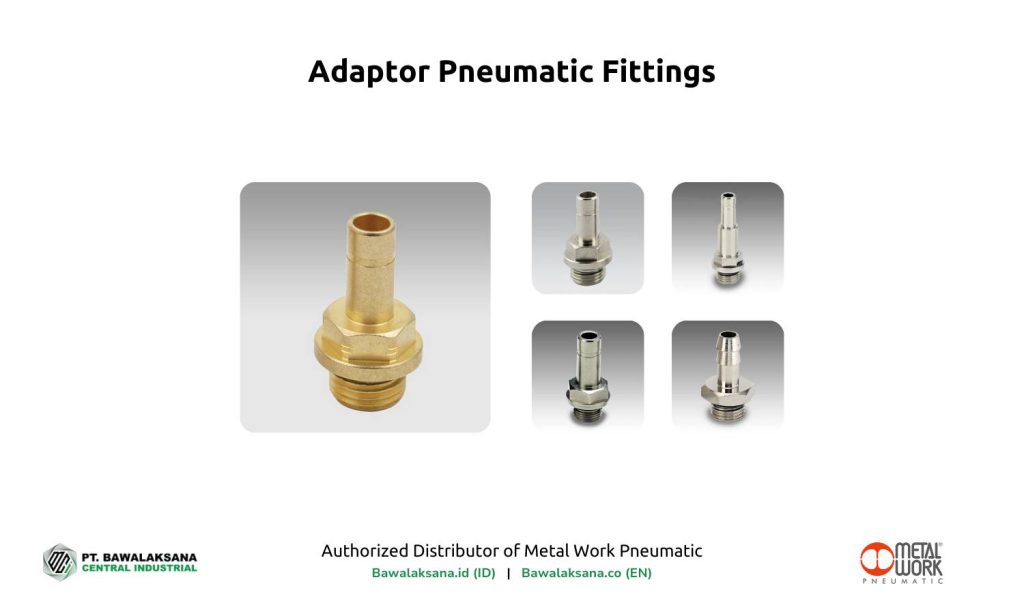

Adapter

Pneumatic adapters serve to convert lines from two different connection types so that they can be connected tightly without any leaks. Adapter fittings connect two different channels that should not be directly compatible.

We need to mention, that pneumatic adapter fittings vary greatly for each vendor. Therefore, we will showcase just a few of them to represent the many types of adapters that exist.

Like straight fittings, pneumatic adapters have a straight shape and only consist of two configurations, such as :

- Thread to plug-in: Connects a threaded connection type to a push-in fitting

- Thread to barb: Connecting threaded connection type into pneumatic hose directly

Notes: The barb connection type is similar to the plug-in but has cleats that can be inserted into the hose and then tightened using clamps. While the plug-in connection type can be connected to push-in fittings quickly and conveniently.

Connection types available for pneumatic adapter fittings include:

- Standard

- Plug-in (push-to-connect)

- Barb

The material for the adapter fitting uses:

- White or yellow brass

Although adapter type fittings are fairly simple as well as straight, their configuration is very critical. By using adapters, different connections can be connected quickly and practically without any potential leakage.

Pneumatic adapter fittings are crucial for connecting pneumatic pipelines of fellow metal or technopolymer (plastic) materials via push-in connections.

That way, the flexibility of the air path of the pneumatic system can be adjusted easily and quickly, without the need for expensive costs.

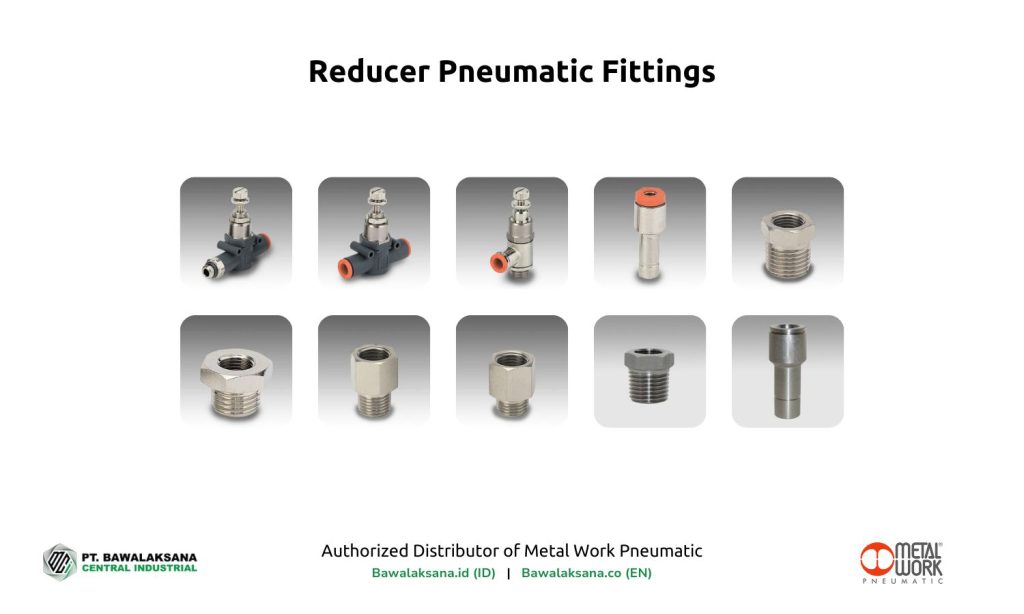

Reducer

Reducer fittings are connecting components for pneumatic lines that function to change the air flow rate.

This type of fitting can be straight or elbow-shaped, while both ends use the same or different connectors.

Reducer fittings can be designed with two different sized duct ends or fitted with a small regulator to make the air duct narrower.

The constriction further contributes to a decrease in airflow rate.

Applications of reducer fittings include:

- Adjust the air flow rate based on system requirements.

- Connecting pneumatic components that have different port sizes.

- Reduce or increase the size of the air duct to suit the needs of the system.

In general, reducer type fittings have several options, including:

- Straight: With a straight shape and one end has a smaller diameter which aims to reduce the air flow rate. In the other version both ends are the same size, but in the center there is a miniature pressure regulator to reduce the air flow rate.

- Elbow: Combines the right angle (90°) format and is equipped with a miniature pressure regulator.

- Thread: Has the shape of a male and female thread with a slightly different diameter at both ends.

Connection types available for reducer fittings include:

- Push-in

- Plug-in (push-to-connect)

- Standard

The material for the reducer fitting uses:

- Technopolymer

- White brass

- Stainless steel

In form, reducer fittings may be considered similar to adapter fittings (for certain variants). However, when viewed in terms of function, the reducer has a very significant difference.

Reducer fitting serves to reduce or enlarge (increaser) the air flow accuracy. While the pneumatic adapter serves to connect two incompatible air ducts directly, both in terms of size and type of connection.

As a consideration, for applications that aim to accurately regulate the speed of cylinder movement, a reducer equipped with a miniature pressure regulator is the best choice.

However, for applications that aim to reduce the airflow rate to a specific component, a thread reducer or plug-in can be used.

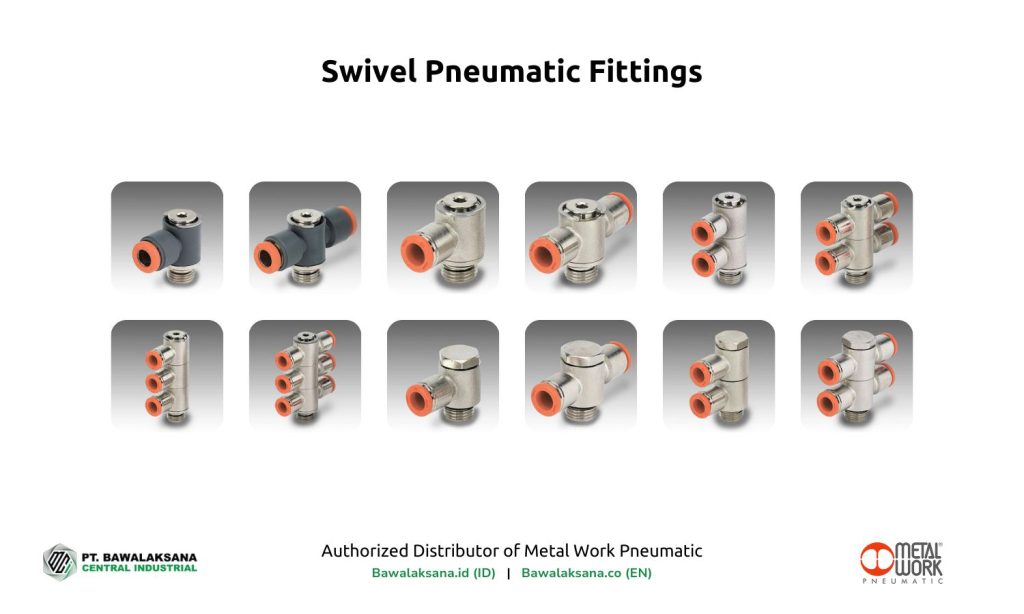

Swivel

Swivel fittings are a type of connector whose body can rotate to adjust the movement of a freely moving pneumatic hose.

This feature reduces the risk of hose rupture due to frequent kinking. This serves to reduce mechanical stress on the hose and extend its service life.

Swivel fittings become very crucial in rotary pneumatic cylinder applications, where the hose needs to follow the mobility of the rotary movement so that it does not break easily due to frequent pulling.

Applications of swivel fittings include:

- Systems that involve mechanical movement in a rotational, linear or combination of both.

- Application to systems where the air path must move freely and adjust to changes dynamically.

- Applications that require customization in installation, following the space available in a limited space.

In general, swivel type fittings have several options, such as:

- Single: Provides 1 rotatable air duct

- Double: Provides 2 air ducts in a straight line and can rotate together

- Dual single: Provides 2 air ducts in parallel that can rotate

- Dual double: Provides 2+2 air ducts in parallel that can rotate

- Triple single: Provides 3 parallel air ducts that can rotate

- Triple double: Provides 3+3 air ducts in parallel that can rotate

The connection types available for swivel fittings are:

- Push-in

The material for the swivel fitting uses:

- Technopolymer

- White brass

The flexibility of the swivel fitting is very important to support the durability of the pneumatic hose. This will also contribute to efforts to reduce the cost of maintenance or replacement of ruptured hoses due to the high mobility of pneumatic tools.

Banjo

A banjo fitting is a type of connector that is similar in shape to a swivel, but cannot rotate. This fitting is used to connect the hose or pipe to other components of the pneumatic system at a predetermined rotating angle.

In other words, the rotating angle of the body part of the banjo fitting cannot be adjusted once the screw (thread) has been tightened.

The banjo is an alternative connector to the elbow that can create a bend in the airflow. However, with this banjo fitting, we can adjust the angle at which the air flow goes when the screw is tightened.

Based on technical specifications, banjo type fittings are intended for high-pressure applications. While swivel fittings are more often used for systems that require flexibility of movement.

In general, banjo-type fittings have several options, such as:

- Single: Provides 1 air duct (cannot rotate).

- Double: Provides 2 air ducts in a straight line (cannot rotate).

- Dual single: Provides 2 air ducts in parallel (cannot rotate).

- Dual double: Provides 2+2 air ducts in parallel (cannot rotate).

The connection types available for banjo fittings are:

- Quick

- Standard

- Compression

The material for the banjo fitting uses:

- White brass

- Stainless steel

In order to make it easier to know the difference in function between swivel and banjo fittings, the following table can be used as a reference:

| Advantages | Swivel | Banjo |

| Rotation | Has the ability to rotate at a certain angle to follow the movement of the pneumatic hose. | Has a fixed turning angle when the fitting screws are tightened. |

| Application | For applications with high flexibility and moving dynamically, such as in linear or rotational pneumatic actuators. | For applications that have a fixed turning angle with ease in adjusting the airflow direction. |

| Flexibility | It has better flexibility with a swivel or rotation angle that can follow the displacement of the hose. This advantage can help prevent the hose from bending or breaking easily. | It has a fixed swivel angle so it cannot follow the dynamic movement of the hose. |

| Operating pressure | More often used for relatively low operating pressures. | Can be used for high operating pressures, and with compression and thread fittings to prevent leakage. |

Accessories Pneumatic Fittings

Accessories pneumatic fittings have a more complex design than some of the fitting types we have mentioned previously. Fitting accessories are connectors in pneumatic lines with several additional features to improve the function and performance of the pneumatic system.

The options available for fitting accessories are numerous and each vendor has different options.

In the following we will mention some of the options for pneumatic fittings accessories:

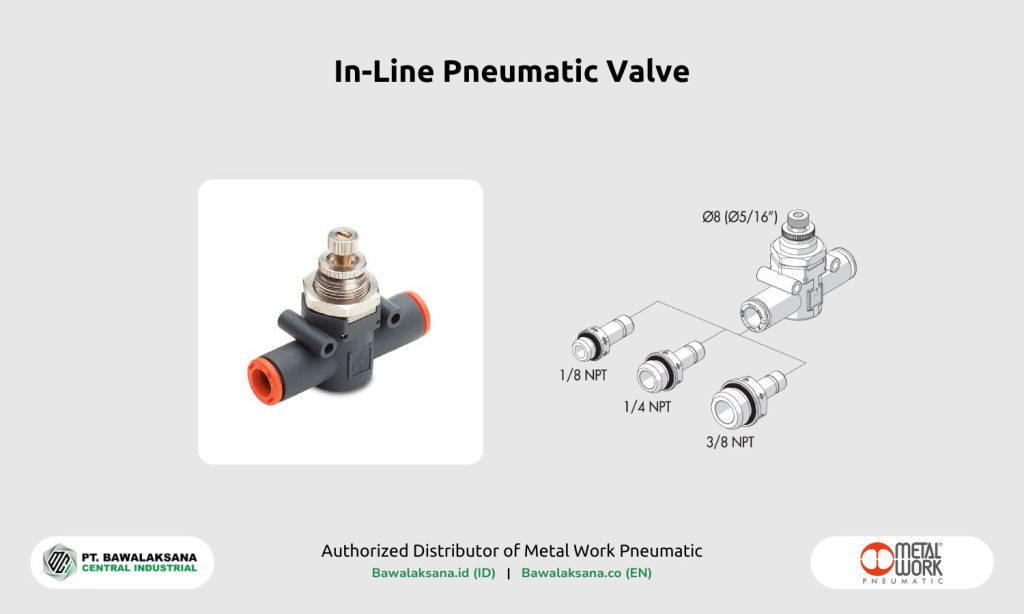

In-Line Pneumatic Valve

An in-line pneumatic valve is a type of fitting that is equipped with a unidirectional valve. These fittings can be connected in series or parallel with other products that have the appropriate connection type.

Its main function is to direct airflow in one direction. When air enters from port 1, the air flow will be continued. However, when air enters from port 2 (opposite direction), the valve will close to stop the air flow.

Features like this are important because they ensure that the airflow directions do not oppose each other, causing turbulence and performance degradation.

In-Line Pressure Gauge

In-line pressure gauges have the function of measuring the air pressure passing through a fitting with accurate readings. These fittings can also be connected in series or parallel with other products that have the appropriate connection type.

In-Line Pressure Switch

Fittings with a pressure switch function provide the benefit of closing or opening airflow that can be controlled via an electrical switch.

The available configurations for this pressure switch are normally open (NO) and normally close (NC).

If the default configuration is NO, the air duct will be sealed. However, when an electrical signal is activated, the valve opens and pressurized air can flow through the fitting until the electrical current is stopped.

In-Line Quick-Exhaust Valve

The quick exhaust valve serves to increase air exhaust, especially for airflow from the opposite direction.

Basically, this valve has a similar function to the In-Line Pneumatic Valve, directing air in one direction. But the difference is that when air comes from the opposite direction, it will be discharged quickly into the atmosphere.

A quick dump valve is often used to quickly exhaust air coming out of a pneumatic cylinder. By doing so, the cylinder movement becomes more responsive as there is no delay in the process of exhausting air into the atmosphere.

This is an explanation of some pneumatic fittings accessories that we can mention. Due to time constraints, we can only show you a few of them.

We believe that there are still many types of pneumatic fittings that are very crucial for industry, but in this article we have not been able to discuss in full.

Even so, of the many fittings that we have described, it is enough to provide an overview of pneumatic fittings and their types.

| Also Read: 10+ Pneumatic System Components to Know |

Types of Materials Commonly Used for Pneumatic Fittings

Bawalaksana.id team has discussed several types of pneumatic fittings that are categorized by type. Next, we would like to briefly explain some of the materials that are commonly used by these fittings.

The following are some types of materials that are commonly used for pneumatic fittings:

Technopolymer

Technopolymer is a type of engineering plastic that has good mechanical, thermal and chemical contact resistance. These engineered plastics are certainly superior to conventional plastics.

The R&D team of a pneumatic component manufacturer has different standards and values for each engineering plastic product. Therefore, the quality of each vendor will also be very different from various sides.

In general, the advantages of technopolymer materials are light weight, corrosion resistance, resistance to high pressure and temperature.

Fittings that use technopolymer materials have the following specifications:

- Operating temperature: -20°C to 60°C

- Working pressure: -0.99 to 12 BAR

It is important to note that every fitting product needs to meet applicable regulatory standards, as a form of compliance with industry norms. Also included in this are the types of pneumatic fittings that we have mentioned above.

Please go to the following page for more details, Product Declarations and Certificates for Pneumatic Components by Metal Work.

White brass

White brass is a component made of brass material with a high zinc (Zn) content. This results in a color that is closer to white than brass which tends to have a yellowish color.

The composition of white brass is of course very different for each pneumatic component manufacturer, as are the specifications offered.

In general, fitting materials that use white brass have the following specifications:

- Operating temperature: -20°C to 60°C / -20°C to 80°C / depending on the type of fitting used

- Working pressure: -0.99 to 16 BAR

Yellow Brass

Yellow brass is a component made of brass material with a higher copper (Cu) content than zinc (Zn). This results in a color that tends to be more golden yellow.

This type of brass is often used in various critical industrial applications due to its corrosion-resistant and heat-resistant properties.

In general, fitting materials that use yellow brass have the following specifications:

- Operating temperature: -20°C to 150°C

- Working pressure: -0.99 to 16 BAR

Stainless steel

Stainless steel is a material made with a blend of steel and contains at least 10.5% chromium (Cr), so it has good resistance to corrosion.

Stainless pneumatic fittings are better than technopolymer or brass. Stainless steel pneumatic fittings are often used in various critical industries because of their strong, heat-resistant and chemical-resistant properties.

In general, stainless steel fittings have the following specifications:

- Operating temperature: -20°C to 150°C / -40°C to 150°C / depending on the type of fittings and tubing used

- Working pressure: -0.99 to 18 BAR

For information, that in choosing the right fitting for your industry, it is necessary to consider a number of aspects such as environmental conditions, temperature, operating pressure, substances that interact with components and other important aspects.

In order to make the right choice, please consult with the engineers in your company or the professionals who recommend the fitting products.

Quality Fittings for Optimal Pneumatic System Performance

Finally, we have completed the discussion of the types of pneumatic fittings for industrial automation systems. With a complete explanation in this article, we can realize the crucial role of the pneumatic connector component and its main function.

With this wide range of options for connecting components, it should be possible to build a pneumatic system with reliable performance.

Choosing the right type of fitting is a vital key to maintaining the productivity of a pneumatic system at an optimal level.

Because fittings are pneumatic components that are closely related to high safety standards in the industrial sector.

Therefore, use fittings that can meet high industry standards and have internationally recognized certificates. This aims to sustain productivity and business sustainability in the long term.

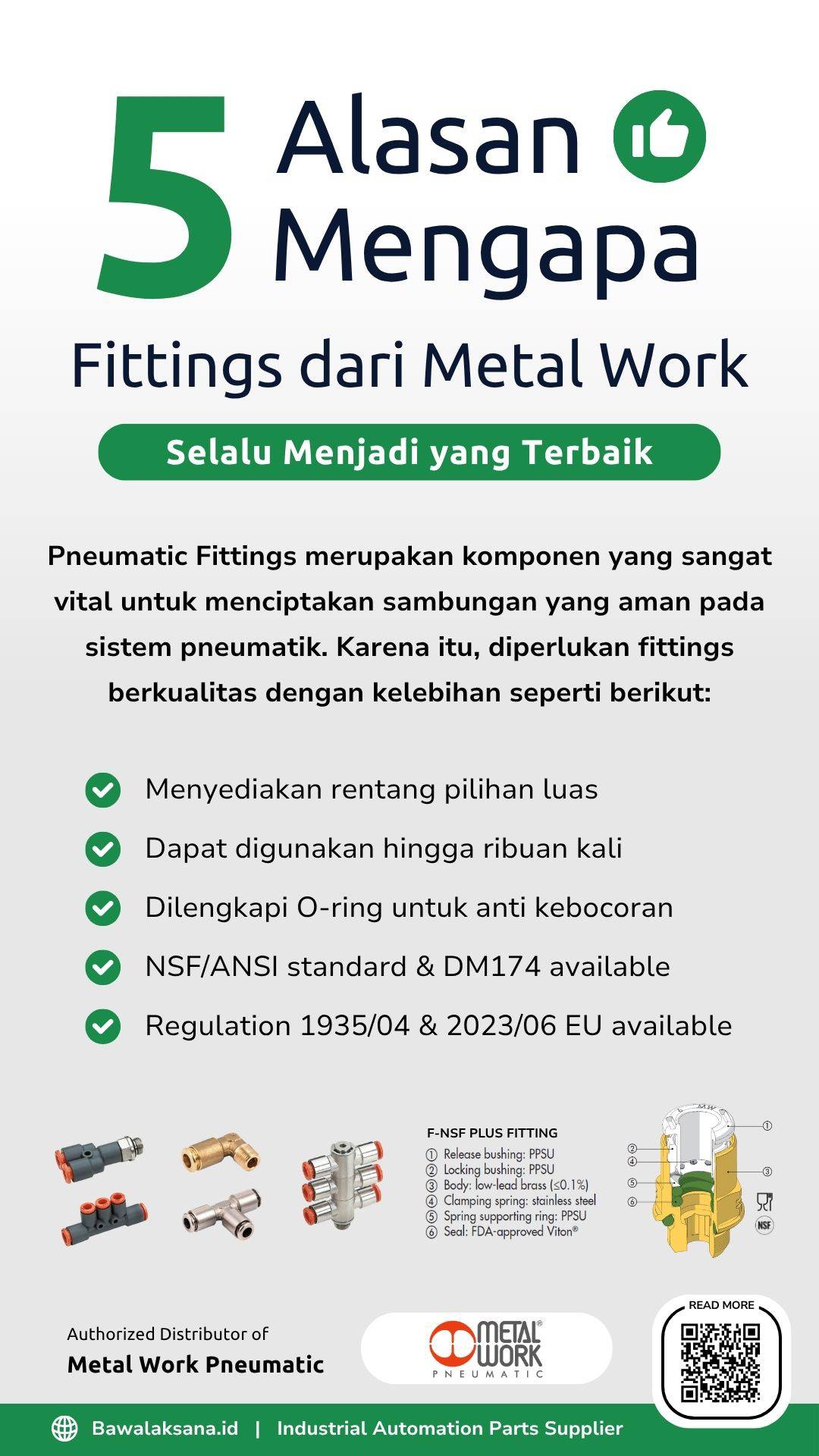

Advantages of Metal Work Pneumatic Fittings

Keep in mind, that there are many types of fittings available for pneumatic systems, including as shown in the following infographic. Each vendor can create different types and designs for fittings, with all their advantages and disadvantages.

The fittings from Metal Work Pneumatic have 4 important advantages as follows:

- A wide range of options to support productivity and application flexibility in various industry sectors.

- It does not require sealant from Teflon material, so it is safe from the risk of fragments being released during installation which could potentially contaminate the production process.

- Each type of fitting features an O-ring to promote a secure and leak-free connection, as well as improved thread seal to beveled, rough and slightly convex surfaces (can be used thousands of times).

- Options are available for the F&B industry sector (NSF/ANSI standard, regulation 1935/04 EU & 2023/06 EU, DM 174).

PT. Bawalaksana Central Industrial is the authorized distributor of Metal Work Pneumatic which can supply a wide and comprehensive range of options for pneumatic automation systems.

We have also become an authorized distributor of Mebra Plastik Italy and Instruments To Industry (ITI) as well as being an Authorized System Integrator for Phoenix Contact.

With the support of a team of professional and experienced engineers, as well as solid partners in Asia and Europe, we are confident that we can be your best partner to build smart and modern manufacturing.

We are currently opening the widest possible collaboration opportunities with your company to realize an advanced and sustainable industry.

If you have any questions regarding our products and services, or those related to industrial automation systems, please consult with our professional team.

Please click the consultation button below to start greeting and talking with the Bawalaksana.id engineer team.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)