Pneumatic systems are essential automation tools that offer various benefits and are vital in multiple industries.

Did you know?

Pneumatic-based automatic machines and industrial equipment have been used since the early 1900s. Even then, these systems had already significantly impacted work efficiency and productivity. It shows that the advantages of pneumatic technology have been recognized for decades.

With the rapid advancements in technology today, we are hopeful that the benefits of pneumatic systems will continue to expand. However, there are still many misconceptions surrounding their potential downsides, such as:

- Air pollution or harmful substances emitted from pneumatic lines

- Cylinders bursting like high-pressure cookers

- Loud, worrisome noises reminiscent of gas leaks

- The risk of serious accidents resulting from air leaks

These concerns are largely unfounded.

Pneumatic systems are recognized as one of the safest technologies in industrial automation. They carry minimal risk of explosion or dangerous leaks, as the air released from these systems is clean and pollution-free.

Since its inception in the 10th century, pneumatic technology has been extensively used and has evolved significantly over time. This advancement has led to increased efficiency and productivity in various applications.

Unbeknownst to many, pneumatic systems play a vital role in our everyday lives. They are found in:

- Air brakes for buses, trains, and airplanes

- Automatic cutting and pressing machines

- Automatic door systems

- Dental treatment equipment

- Air conditioners and refrigerators

- Food industry applications

- Packaging systems

- The automotive sector

- And beyond

These facts illustrate how deeply embedded pneumatic systems are in our daily lives, especially in industrial operations.

To provide you with a thorough understanding of pneumatic systems, the Bawalaksana Central Industrial team is excited to explore these systems’ advantages and disadvantages for industrial use.

By reading this article, you’ll gain valuable insights into the multitude of benefits that pneumatic systems can bring to your industry and your company.

Advantages of Pneumatic Systems

Pneumatic systems are widely recognized for their numerous advantages, which include:

- Operational safety

- Flexibility in technology integration

- Low initial investment costs

- Ease of maintenance

- High component durability

Beyond these five key points, a significant benefit of pneumatic automation systems is their capability to uphold stringent cleanliness standards. This strong point explains why pneumatic system automation is extensively employed in critical industries such as automotive manufacturing, electronics, food and beverage, petrochemicals, and pharmaceuticals.

In a previous article, we delved into 4 Key Advantages of Pneumatic Systems, emphasizing their benefits and strategies for optimizing performance. This piece will uncover several additional advantages that weren’t addressed earlier.

Let’s take a closer look at the full spectrum of benefits pneumatic systems bring to the table:

1. Seamless Integration with Technology

One of the most notable advantages of pneumatic systems is their seamless integration with technology. While we’ve touched on this benefit in various articles, it’s worth revisiting due to its ongoing significance.

Pneumatic system automation has become a staple in many industries. Its continued relevance is fueled by rapid technological advancements and straightforward integration, making it a lasting solution.

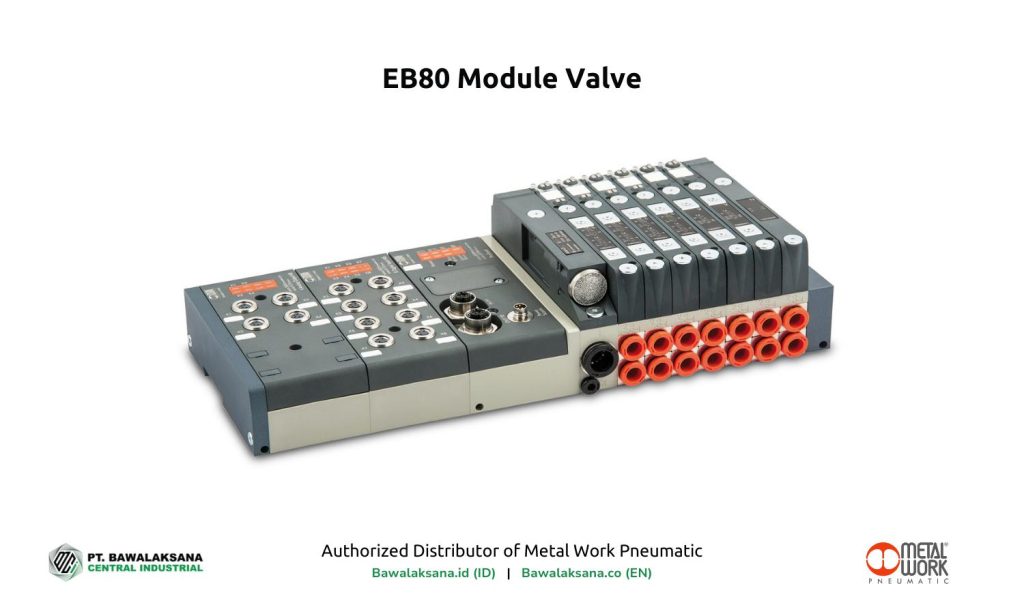

There are numerous ways to connect pneumatic systems with cutting-edge technology. For instance, introducing innovative components like the EB80 Island Valve and FLUX Flowmeter exemplifies this integration.

Our article Strategic Actions to Improve Pneumatic System Efficiency discusses how these components contribute to energy savings. They enhance machine performance and play an essential role in analyzing performance data, predictive diagnostics, and evaluating energy consumption on the factory floor.

By implementing the EB80 Island Valve and FLUX Flowmeter, your company’s pneumatic plant can reap a host of advantages, such as:

- Enhanced operational control with a modern touch allows seamless integration into PLC systems.

- Streamlined management of multiple pneumatic valves and actuators at once.

- The ability to record statistical data at the machine level, which can store information for up to 50 years, aids in operational analysis and predictive diagnostics.

- Engineers can monitor energy parameters in real time through an IoT-based system, which tracks energy consumption and allows for the early detection of potential air leaks.

- Collecting both qualitative and quantitative data at the machine level supports preventive maintenance and timely corrective actions to boost overall energy efficiency across the plant.

- Valuable insights include predictions for component end-of-life, long-term system assessments, and improved spare parts management.

By embracing these technologies, your pneumatic operation can significantly enhance efficiency and reliability.

Effective management of qualitative and quantitative data at the pneumatic machine level is crucial for optimizing information processing within ERP and supervisory systems.

However, traditional PLC systems cannot currently conduct comprehensive monitoring of statistical data or predictive diagnostics directly at the machine level, such as for valves, actuators, sensors, and switches.

This gap underscores the need for more advanced technologies, like the EB80 Island Valve and FLUX Flowmeter, which can facilitate more innovative and more efficient data management in the era of Industry 4.0.

2. Reliable Operation in Extreme Environments

Pneumatic systems stand out as dependable automation solutions in a variety of extreme environments, including:

- Car wash facilities, where humid and cold conditions are common.

- Petrochemical production sites often expose equipment to harsh chemicals and high temperatures.

- Manufacturing plants face heavy workloads, elevated temperatures, and even dusty conditions such as those found in cement factories.

- Food and beverage industries, where maintaining cleanliness and hygiene is paramount, frequently encounter components exposed to cleaning agents.

- Industrial settings require highly resilient components that can perform well with minimal maintenance.

- ATEX environments, where components need to have antistatic electrical resistivity to reduce the risk of explosions.

It’s crucial to recognize that stringent regulations regarding the use of electronic equipment and automation devices govern ATEX-classified environments. In these sectors, static electricity from surrounding materials can present a real danger, potentially leading to fires or explosions.

The encouraging news is that pneumatic systems provide an excellent solution to these challenges.

Numerous manufacturers can now supply pneumatic components that meet ATEX standards, and one of our top recommendations is Metal Work Pneumatic.

Metal Work is an industrial group specializing in designing, producing, and marketing components for pneumatic automation systems. With over 50 years of experience, Metal Work has established itself as a global leader in innovation, precision, and outstanding quality for pneumatic devices.

Metal Work’s products meet European standards for pneumatic components used in ATEX environments, ensuring they suit extreme settings such as dusty conditions, chemical exposure, and high temperatures. Relying on components from a reputable manufacturer is crucial to achieving this level of dependability.

Furthermore, it’s worth mentioning that pneumatic systems operating in harsh environments need regular maintenance to ensure smooth operation and to extend their lifespan. Proper upkeep is key to keeping these systems running efficiently.

3. Quick and Responsive Motion with Adjustability

One of the standout benefits of pneumatic systems is their quick and responsive motion. This feature can boost production output, cost efficiency, and business profitability.

The magic happens thanks to the valves, which manage the airflow in and out of the pneumatic cylinders and act as the system’s primary drivers.

Pneumatic systems offer key advantages, such as speed and responsiveness. However, to ensure they fit seamlessly into your production line, it’s crucial to select the correct type of cylinder and adjust its speed as needed.

A single pneumatic facility may incorporate numerous cylinders of various types and sizes. The EB80 Valve Module guarantees smooth and synchronized operation across all cylinders. This module helps control the movement rhythm of each cylinder, ensuring that the actuators work together harmoniously to align with the production line.

Can the speed of a pneumatic cylinder’s motion be adjusted?

This is a frequently asked question regarding controlling the actuation speed of pneumatic cylinders. Fortunately, there are several ways to modify how fast these cylinders move. You can achieve this by adding components like:

- Speed control fittings

- Quick exhaust valves

- Speed control mufflers

Additionally, with advancements in technology, Hydraulic Pneumatic-System actuators now offer even more sophisticated speed control options, including features like:

- Skip: Changing the actuator’s movement from fast to slow

- Stop: Temporarily pausing the stroke

- Speed regulation: Setting an adjustable stroke speed

To dive deeper into these capabilities, check out the following video.

It’s essential to understand that pneumatic actuators exhibit continuous movement throughout the stroke.

The continuous movement means that once the cylinder is activated—whether it’s extending or retracting—the piston rod will keep moving until it hits a predetermined endpoint mechanically defined by a stopper or electronically by a sensor.

This is quite different from electric actuators, which can position themselves at any desired point based on the motor’s rotation and guidance from the PLC unit.

While electric actuators shine in motion control, pneumatic actuators stand out regarding speed.

4. Simple Components, Yet High Performance

Pneumatic systems are a key technology in industrial automation, combining simple components with impressive performance. Remarkably, these systems can generate substantial power relative to their compact size. By avoiding complex devices, pneumatic equipment operates with considerable force and high speed, making it an ideal choice when weight and space constraints are paramount in your industry.

Thanks to their straightforward design and significant power output, pneumatic components boast an excellent power-to-weight ratio. For small-scale businesses, the convenience of loading all pneumatic equipment onto a single truck is an important advantage.

Furthermore, these components’ lightweight and compact nature allows for easy relocation with just one or two people.

This ease of mobility enables quick transitions from one site to another, highlighting the practicality of pneumatic systems. Ultimately, they present a lighter and more cost-effective solution than automation systems that rely on electric or hydraulic actuators.

5. Ability to Maintain High Cleanliness Standards

Thanks to their use of compressed air as a power source, pneumatic systems emerge as a top choice for applications that demand exceptional cleanliness. The air in these systems is thoroughly filtered and passes through an air dryer, effectively removing any moisture. This meticulous process ensures that the air released by pneumatic systems is clean and does not harm the environment.

In sectors where high cleanliness is crucial—such as semiconductor manufacturing, pharmaceuticals, and food and beverage (F&B) industries—pneumatic systems easily meet stringent requirements. Nowadays, many products and components are specifically designed for these critical industries.

To explore this further, we’ve published articles on Pneumatic System Applications for Electronics Manufacturing and the F&B Industry—these articles concisely overview pneumatic systems’ roles and functions in these sectors.

Suppose you’re interested in pneumatic components that meet stringent cleanliness standards. In that case, we invite you to check out our page dedicated to Pneumatic Systems for Life Science and the Food and Beverage Industry.

It’s important to highlight that pneumatic system leaks will not harm the environment or lead to significant negative consequences. This starkly contrasts hydraulic systems, where leaks can result in serious issues despite preventive efforts.

Oil or hydraulic fluid spills can contaminate surrounding soil, water, and ecosystems, causing substantial damage.

6. Low Air Pressure Operation

Pneumatic systems function at relatively low air pressure, typically 72 to 145 psi (5 to 10 BAR). This contrasts hydraulic systems operating at much higher pressures between 1,000 and 5,000 psi (69 to 344 BAR).

Due to this lower pressure range, pneumatic systems are generally safe for use across various industrial sectors. It is a misconception to think that pneumatic components pose a high risk of explosion or danger, as some people may fear.

Even with the lower operating pressure, pneumatic systems offer quick and responsive movement. This is because air, having a much lower density than hydraulic fluids, is easily compressible.

Additionally, the airlines in these systems carry no risk of electric shock, making them safe to handle with bare hands or other body parts. Electricity only flows through components like compressors, valves, or flowmeters, meaning most of the system remains safe.

Furthermore, the air expelled from pneumatic components is entirely free of toxic substances, ensuring a safe environment for operators nearby. The air that enters and exits the pneumatic system is filtered, making it suitable for use in industrial settings.

7. Environmentally Friendly

As previously highlighted, pneumatic systems are inherently safe for the environment. It is evident in several ways:

First, the air that enters the pneumatic system is meticulously filtered and dried, ensuring that the air released remains clean and dry.

In industrial settings, every pneumatic component undergoes regular cleaning to remove dust, oil, and other contaminants and maintain its top condition.

Pneumatic components are often made from stainless steel for critical applications, such as in the petrochemical and food and beverage industries. This material is easy to clean, non-contaminating, and chemically inert.

Moreover, a broad selection of high-quality products meets stringent cleanliness standards, ensuring environmental safety.

Given these advantages, pneumatic systems are an excellent choice for green manufacturing and stand out in industrial automation.

Did you know that most vendors of pneumatic components typically hold internationally recognized declarations and authenticity certificates?

These documents cover the types of materials used and the manufacturing processes involved and provide assurances regarding the reliability of their products for critical applications. In essence, reputable manufacturers of pneumatic components can confidently assert that their product lines adhere to high standards.

For instance, consider two noteworthy examples of declarations and product certificates related to pneumatic components:

- Product Declarations and Certificates for Pneumatic Components by Metal Work

- Product Declarations and Certificates for Pneumatic Tubing by Mebra Plastik Italy

We encourage you to verify the certificates for your company’s pneumatic products as a best practice. This step helps ensure that each component performs effectively and minimizes environmental impact.

8. Free and Sustainable Energy Source

One of the standout benefits of pneumatic systems is that their energy source is essentially free. Air, the primary driver, can be sourced at no cost. All required is an air compressor, which draws in air from the environment and compresses it into pressurized air. The operational costs of a pneumatic system largely hinge on this air compressor.

According to a scientific article by Science Direct titled “Enhanced energy conservation and response accuracy of a pneumatic control system,” these systems are recognized for their low operational costs, pollution-free performance, and simple maintenance.

The article highlights that pneumatic systems account for approximately 9% of the total industrial electricity consumption in the United States, while in Europe, this figure is around 10%.

Given our pressing energy challenges, concerns have emerged regarding the inefficiencies and considerable waste associated with pneumatic systems. Consequently, energy-saving strategies for these systems have sparked lively discussions among academic institutions and industrial companies.

The encouraging news is that addressing the Dead Zone in solenoid valves can lead to savings of up to 26.27% in air consumption and 32.35% in power consumption.

It’s important to understand that the Dead Zone refers to a specific range where a system’s output remains relatively unchanged despite fluctuations in the input signal to the on-off solenoid valve. When the solenoid valve’s performance declines, the pneumatic cylinder loses its responsiveness. This decreased responsiveness negatively impacts airflow control and the pneumatic cylinder’s overall energy efficiency.

A larger Dead Zone leads to longer response times for the pneumatic cylinder, resulting in lower productivity, diminished product quality, higher energy consumption, and various other complications. One potential solution to mitigate the effects of the Dead Zone is to boost the input voltage to the on-off valve. However, this approach can lead to increased temperatures and higher electricity usage.

To tackle this issue effectively, technological advancements can provide a more responsive valve performance by utilizing an electro-pilot system. This system can be paired with intelligent control mechanisms that allow for an initial increase in voltage. Once the electro-pilot engages, the voltage reduces, and the on-off valve still operates effectively.

The great news is that the EB80 Island Valve electro-pneumatic system delivers outstanding performance. With its Speed Up Technology, this system ensures the solenoid valve operates seamlessly while significantly reducing the pneumatic cylinder’s response time.

The EB80 Island Valve initially consumes 3W of energy for the first 15 milliseconds during electro-pilot activation. After this brief period, the energy consumption drops to just 0.3W as the system continues to operate.

This innovation generates notable energy and compressed air savings without sacrificing the pneumatic system’s productivity. Thus, technology plays a pivotal role in enhancing the efficiency and effectiveness of pneumatic automation systems.

9. Ease of Maintenance

One of the key advantages of pneumatic systems is their ease of maintenance. This feature is often regarded as the most appealing aspect of pneumatic devices, primarily because their components are generally straightforward and not overly complicated.

Pneumatic components are designed for durability and a long service life. However, it’s important to note that these systems still require regular maintenance. Diligent upkeep is essential to ensure that the system runs efficiently and smoothly.

We detailed this process in our article, 10 Essential Steps for Maintaining Pneumatic Systems. Adhering to a regular maintenance schedule can reduce downtime by as much as 70% and enhance overall efficiency by up to 30%.

It’s essential to recognize that pneumatic systems are susceptible to three main issues: dust, moisture, and air leaks. If these problems aren’t effectively addressed, they can reduce productivity and unnecessary energy waste.

To ensure proper maintenance of pneumatic systems, consider the following important guidelines:

- Regularly check the FRL (Filter-Regulator-Lubricator) unit and the pneumatic hoses and fittings.

- Keep all components clean by removing dust and moisture.

- Lubricate and grease every moving part to ensure smooth operation.

- Drain accumulated water from critical points such as FRL units, drain valves, water separators, and air reservoirs.

- Conduct routine maintenance on actuator units based on their usage cycles.

- Maintain clean, dry air in the system.

- Install diagnostic tools and air-leak detectors to monitor efficiency.

- Keep an eye on air pressure, ensuring it stays within safe limits as required by the system, ideally between 5 to 10 BAR.

Following these tips can help keep your pneumatic systems running efficiently.

We want to emphasize that while maintaining pneumatic components is relatively straightforward, the company’s operator team needs to receive appropriate training.

Given the increasing complexity of pneumatic technology, enhancing their knowledge of pneumatic maintenance is vital. This proactive approach can help your company’s pneumatic plant prevent significant losses from negligence in assessing overall system performance.

That wraps up our discussion of pneumatic systems’ nine advantages in industry and manufacturing. We recognize that additional benefits are not covered here; however, the nine points we’ve outlined should suffice due to time constraints.

Now, let’s focus on some of the disadvantages of pneumatic systems.

Disadvantages of Pneumatic Systems

The same applies to pneumatic systems when discussing the downsides of automation systems in manufacturing. Commonly cited drawbacks of these systems include air leakage and energy loss.

However, it’s worth noting that we can often mitigate these challenges by adopting appropriate technology and regular maintenance practices. Below, the team at Bawalaksana will delve into the disadvantages of pneumatic systems and present practical solutions to address these issues.

1. Air Leakage and Energy Waste

Air leaks in pneumatic systems can lead to significant energy waste if not properly managed. However, it’s essential to recognize that the potential for these leaks often arises from challenging conditions in the field that make these systems vulnerable.

In a pneumatic circuit, pressurized air travels through pipes from the compressor to the air reservoir and, ultimately, to the pneumatic panel. This pressurized air is then directed through pneumatic hoses connecting to valves, fittings, and cylinder actuators.

These hoses often navigate through tight and winding spaces and must endure high mobility due to the movement of cylinders or robotic arms. Due to wear and degradation, such demanding conditions can lead to hose compression, stretching, bent, or even rupture over time.

This is among the factors why pneumatic systems are prone to leakage, but it is necessary to support the demand and productivity in the manufacturing sector. Thus, pneumatic system automation can complete critical tasks even without human intervention.

While air leakage is a downside, it’s worth noting that pneumatic systems have several advantages, such as their ability to adapt to varying field conditions, ultimately enhancing factory productivity.

How to Address the Risk of Air Leakage in Pneumatic Systems

The good news is that air leaks in pneumatic systems are straightforward to identify and rectify. Various technologies can assist in this process, such as:

- Flowmeter Flux: This tool helps pinpoint wasted air usage and assesses energy consumption trends.

- EB80 Island Valve: This device serves as both a control mechanism for cylinders and valves and a diagnostic tool to monitor wear in pneumatic machinery, which can lead to leaks and inefficiencies.

- Ultrasonic Acoustic Detector: This instrument detects hissing sounds that signal potential air leaks within pneumatic facilities.

In addition to utilizing these technologies, careful planning during system installation can mitigate energy loss. Consider the following best practices:

- Design air pathways with efficiency in mind to avoid unnecessary complexity that could result in pressure drops and diminished performance.

- Regularly maintain air piping to prevent issues such as corrosion.

- Select the right type and size of pneumatic hoses based on the application, ensuring they comply with industry standards. For instance, opt for PU hoses that offer excellent flexibility and durability when dealing with high-mobility robot applications.

- Choose suitable pneumatic cylinders tailored to the industrial environment, lifting loads, and specific requirements (like food-grade, chemical resistance, or lubricant-free options).

- Invest in high-quality components and supporting technology that promise longevity.

- Properly manage air moisture issues using suitable methods to ensure system reliability.

By taking these steps, you can significantly reduce the risk of air leakage and ensure optimal performance from your pneumatic systems.

2. Disturbing Noise Levels

Noise is a notable downside of pneumatic systems that warrants attention. Typically, this noise originates from three main components: the air compressor, solenoid valve, and pneumatic cylinder.

Noise from the Air Compressor

The most significant noise usually comes from the air compressor. However, if your pneumatic facility utilizes an air reservoir tank to store energy, the noise can be mitigated when the compressor is turned off.

Generally, the noise produced by pneumatic systems isn’t particularly grating; wearing earplugs isn’t necessary while working in most pneumatic plants. However, the compressor noise can become quite distracting for individuals who are more sensitive to sound, making them feel the need to distance themselves from the working environment.

To address this concern, consider creating a quiet area away from the production zone. This approach allows production operators to focus on their tasks without being disrupted by the loud sounds generated by the air compressor.

Noise from the Solenoid Valve

When the pneumatic system operates, the solenoid valve can produce noticeable noise, particularly as air is expelled into the atmosphere. Fortunately, this issue can be easily resolved by installing an appropriate silencer, which effectively lowers the decibel level of the air release from the valve.

Noise from the Pneumatic Cylinder

While the cylinder actuator does generate some sound, it’s generally not loud. However, the accumulated noise can become quite disruptive if multiple cylinders function simultaneously within a facility. Moreover, if a cylinder emits unusually loud or squeaky sounds, it could be a sign that the seal or gasket is worn and needs to be replaced.

3. Dependence on the Air Compressor

Compressed air is the pneumatic system’s primary energy source, making the compressor an essential component. This device draws air from the atmosphere and compresses it into pressurized air. If the compressor fails to function, the pneumatic system will be inoperable unless air is still available in the air reservoir tank.

While this dependence is a drawback, it is reasonably acceptable, as hydraulic systems also rely on a motor to pump pressurized fluid throughout their operation.

4. Limited Motion Control and Force

One notable drawback of pneumatic systems is their limited control over motion and force. However, this limitation is relatively minor and shouldn’t be a dealbreaker when considering their use.

In manufacturing automation, not every production station needs intricate motion control or extremely high force levels. There’s ample opportunity for pneumatic systems to enhance productivity on the factory floor.

For instance, tasks such as cutting raw materials into smaller pieces or transporting items from one location to another don’t typically demand high precision or a significant amount of force.

Various technologies are now available to improve motion control for pneumatic cylinders. Pneumatic systems are often paired with robotic arms or advanced manufacturing mechanisms, effectively fine-tuning pneumatic equipment’s control and working speed.

Despite their limitations, pneumatic systems can handle various tasks within the industry and manufacturing sectors. For more details, we’ve compiled a summary of the significant roles pneumatic systems play in different industrial applications on our page, which is dedicated to Examples of Pneumatic System Applications.

5. Vulnerable to Moisture and Dust

Moisture and dust pose significant challenges to the efficiency of pneumatic systems. Dust can obstruct air passages and increase friction in pneumatic actuators, leading to decreased performance. On the other hand, moisture can result in corrosion and accelerated wear on components, ultimately shortening their lifespan.

Dust and moisture contamination can lead to production failures and compromised quality in critical industries such as electronics manufacturing, food and beverage, and pharmaceuticals. Dust accumulates on FRL units, pneumatic cylinders, solenoid valves, and other moving parts. Additionally, moisture can build up along airlines, collecting water in certain areas and further exacerbating the issues.

Water can accumulate in pneumatic lines for several reasons, including:

- When air is compressed, moisture present in humid air tends to stick to nearby surfaces.

- Temperature fluctuations can lead to water vapor condensation, particularly during warmer months.

- Variations in temperature along the pneumatic lines, transitioning from hot to cold, can also condense water vapor, leading to gradual accumulation.

To tackle this issue effectively, pneumatic systems must incorporate air dryers and perform regular inspections of the FRL (Filter, Regulator, Lubricator) units and several key vulnerable points in the system.

A previous article explored How to Remove Water from Pneumatic Systems and Understand Its Importance. Please refer to that discussion for a detailed overview of how to combat moisture issues in your company’s pneumatic setup.

6. Sensitivity to Vibration

Pneumatic systems tend to have robust main driving components that can effectively withstand vibrations. Cylinder actuators are securely fastened, providing stability during operation.

However, measurement devices, control units, and other electronic equipment are sensitive to vibrations, as they house sensors and electronic elements that can be disrupted while the pneumatic system is in operation.

To mitigate this issue, it’s advisable to position devices such as flowmeters, electro-pneumatic units, valves, and FRL units at a distance from the cylinder actuators or any primary vibration sources. Following this guideline can enhance the pneumatic system’s overall stability and performance.

We’ve mentioned all six disadvantages of pneumatic systems in industrial automation. Having covered these points, we arrive at the final but essential consideration regarding pneumatic systems, as summarized by the Bawalaksana Central Industrial team.

We hope this article has provided your company with valuable insights, empowering you to make informed decisions and thoughtful plans if you want to implement pneumatic system automation.

It’s essential to recognize that pneumatic systems may not be the perfect fit for every industrial or manufacturing sector. Nevertheless, in various scenarios, pneumatic technology can be the optimal choice.

Before you finish reading, please check out the upcoming brief segment, which discusses the key factors necessary to maintain pneumatic efficiency at its best.

Factors for Enhancing Pneumatic System Efficiency

The efficiency of a pneumatic system is determined by several key factors, with the most important being:

- Component Type and Quality: The longevity of a pneumatic system largely hinges on the types of components used, the quality of materials, and the manufacturer’s design. These aspects become even more pronounced when the system operates in extreme environments or high temperatures.

- Technology Employed: Effective technology is vital for keeping efficiency at peak levels. Utilizing the right technology enables your operational team to conduct predictive diagnostics and schedule maintenance, helping to avoid potential system failures.

- Pneumatic Plant Design: Achieving optimal efficiency requires careful planning and execution. This often depends on the collaboration between the vendors and the engineering teams your company engages with to develop the pneumatic facility.

If the current pneumatic plant isn’t performing well, the best action is to conduct a thorough system audit and performance evaluation. After this, consider gradually replacing less effective pneumatic components with better performance upgrades.

Ultimately, no automation system is flawless, and pneumatic systems are no exception. When we examine the essential role of pneumatic technology in critical industries, it’s clear that it remains a highly favored option. This technology offers practical solutions for processes that demand exceptional durability. Additionally, it requires a minimal initial investment and is straightforward to maintain.

Pneumatic systems also uphold high cleanliness standards and show impressive resilience in harsh industrial conditions. Their inherent simplicity has made them particularly popular in high-productivity manufacturing environments.

Moreover, the field of pneumatics is advancing rapidly, providing significant flexibility for integration with modern technology. We are optimistic about the various innovations in pneumatic automation systems, which are allowing more industries and manufacturers to reap the benefits of enhanced industrial productivity.

PT Bawalaksana Central Industrial proudly serves as the official distributor for Metal Work Pneumatic. We deliver a wide range of comprehensive solutions tailored to enhance the implementation of pneumatic automation systems within your organization.

Our expertise spans various industries, ensuring we can meet the unique demands of your specific applications.

In addition, we are an authorized system integrator for Phoenix Contact, which allows us to supply high-quality components and offer extensive support and integration services for automation in the manufacturing sector.

Our capabilities enable us to optimize your production processes, increase efficiency, and drive innovation.

Bawalaksana’s team of professional engineers is committed to collaborating with you to bring your vision of an innovative industry to life in today’s digital era. We understand the complexities of modern manufacturing, and we are equipped to guide you every step of the way.

For a deeper understanding of our cutting-edge innovations, diverse product offerings, and tailored services, we invite you to connect with our engineering team through the consultation button below.

We look forward to partnering with you to achieve a successful automation journey.

Romanta Pinrih Linuwih

Pneumatic Automation Systems Expert

This article was written in collaboration with Romanta Pinrih Linuwih, an expert in Pneumatic Automation Systems, to ensure accuracy and high quality insights.

![10+ Examples of Pneumatic Tools in Daily Life and Industry [2025]](https://bawalaksana.co/wp-content/uploads/2025/05/Sandblasting-large-diameter-pipes-to-remove-surface-contaminants-1080x675.jpg)